Preparation of spent coffee grounds-rubber composites using natural rubber latex as binder

DOI:

https://doi.org/10.55713/jmmm.v32i4.1543Keywords:

natural rubber latex, rubber composite, spent coffee grounds, green binderAbstract

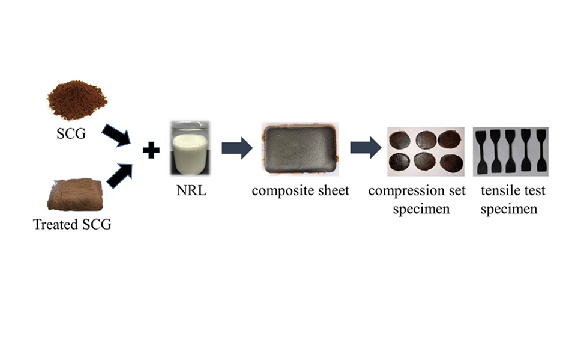

The aim of this work was to explore the use of natural rubber latex (NRL) as a natural binder (according to the BCG concept) to replace commercial synthetic binders such as polyurethane resin. A composite sheet of spent coffee ground (SCG) and natural rubber (NR) was prepared by mixing of SCG in NRL compounds having concentrations of 30% and 60% dry rubber content (DRC). The amount of SCG in the composites was varied from 33 to 167 part per hundred rubber (phr). The mixture was cast in a mold to form a thin sheet then left drying at room temperature for 24 h. TGA thermogram shows 3 decomposition stages composed of moisture (including volatile matters), polysaccharide and lipid at 44%, 42% and 13% weight, respectively. Hardness (Shore A) increases gradually with increasing the amount of SCG, while tensile strength and elongation at break tend to decrease. Tensile strength decreases from 2.6 MPa to 1.2 MPa for the composites containing 33 phr and 133 phr of SCG, respectively. Alkaline surface treatment of SCG could improve the adhesion between SCG and NR as evidenced by the increase in tensile strength, elongation at break and compression set properties.

Downloads

References

C. Siriwong, S. Boopasiri, V. Jantarapibun, B. Kongsook, S. Pattanawanidchai and P. Sae-Oui, “Properties of natural rubber filled with untreated and treated spent coffee grounds,” Applied Polymer Science, vol. 135, pp. 46060-1- 46040-9, 2017.

A. S. Campos de Bomfim, D. Magalhaes de Oliveira, H. J. C. Voorwald, K. C. Coelho de Calvalho Benini, M. J. Dumont and D. Rodrigue, “Valorization of spent coffee grounds as precursors for biopolymers and composite production,” Polymer, vol. 14, no. 3, pp. 14030437-1-14030437-25, 2022.

F. V. Wadson, P. L. Daniela, S. F. Adriana, and S. O. Leandro, “Effect of peroxide treatment on functional and technological properties of fiber-rich powders based on spent coffee grounds”, International Journal of Food Engineering, vol. 2, pp. 42-47, 2016.

R. Leemasathaporn and T Tachatiemchan, “A preliminary study on the application of coffee grounds in latex,”APEC Youth Scientist Journal, vol. 8, pp. 9-14, 2016.

I. V. Telekhov, and E. M. Chistyakov, “Binders used for the manufacturing of composites materials by liquid composite molding”, Polymer, vol. 14, no. 87. pp. 14010087-1-14010087-30, 2022.

L. F. Ballesteros, J. A. Teixeira, and S. I. Mussatto, "Chemical, functional, and structural properties of spent coffee grounds and coffee silverskin,” Food Bioprocess Technol, vol. 7, pp. 3493-3503.

J. S. Tango, “Industrial utilization of coffee and its byproducts,” International Journal of Food Engineering, vol. 28, pp. 48-73, 1971.

S. S. Sikka, M. Bakshi and J. S. Ichhponani, “Evaluation un vitro of spent coffee grounds as a livestock feed,” Agricultural Wastes, vol. 13, pp. 315-317, 1985.

C. S. Wu, “Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability,” Polymer Degradation and Stability, vol 121, pp. 51-59, 2015.

W. Pechurai, S. Saengdian, and W. Chairuen, Proceedings of the 10th International Conference on Science, Technology and Innovation Sustainable Well-Being. Vientiane, Lao PD, 2018.

G. Raju, M. Khalid and H. M. Akil, “Epoxidised natural rubber filled spent coffee ground green biocomposites”, Polymer and the Environment, vol. 30, pp.1415-1422, 2022.

S.M.K. Thiagamani, R. Nagarajan, M. Jawaid, V. Anumakonda and S. Siengchin, “Utilization of chemically treated municipal solid waste (spent coffee bean powder) as reinforcement in cellulose matrix for packaging applications," Waste Management, vol. 69, pp. 445-454, 2017.

W.A. Kyei-Manu, C.R. Herd, M. Chowdhury, and J.J Busfield, “The Influence of colloidal properties of carbon black on static and dynamic mechanical properties of natural rubber,” Polymers, vol. 14, pp. 1194-1213, 2022.

A. A. Cerit, M. B. Karamis, F. Nair, and K. Yildizli, “Effect of reinforcement particle size and volume fraction on wear behavior of metal matrix composites,” Tribology in Industry, vol. 30, pp. 31-36, 2008.

F. Kundie, C. H. Azhari, A. Muchtar, and Z. A. Ahmad, “Effect of filler size on the mechanical properties of polymer-filled dental composites: A review of recent developments,” Journal of Physical Science, vol. 29, no. 1, pp. 141-165, 2018.

Y. S. Shi, X. Feng, H. Y. Wang, C. Liu, and X. H. Lu, “Effect of filler crystal structure and shape on the tribological properties of PTFE composites,” Tribology International, vol. 40, pp. 1195-1203, 2007.

Z. X. Ooi, H. Ismail and A. A. Bakar, “Study of the ageing characteristics of oil palm ash reinforced natural rubber composites by introducing a liquid epoxidized natural rubber coating technique,” Polymer Testing, vol. 37, pp. 156-162, 2014.

W. Cao, S. Liu, X. Ciu and X. Yu, “Effect of crumb rubber particle size and content on properties of crumb rubber modified (CRM) asphalt,” Mechanics and Materials, vol. 99-100, pp. 955-959, 2011.

C. Wongsiridetchai, W. Chiangkham, N. Khlaihiran, T. Sawangwan, P. Wongwathanarat, T. Charoenrat, and S. Chantorn, “Alkaline pretreatment of spent coffee grounds for oligosaccharides production by mannanase from Bacillus sp. GA2(1),” Agriculture and Natural Resources, vol 52, pp. 222-227, 2018.

X. Li, L. G. Tabil, and S. Panigrahi, “Chemical treatment of natural fiber for use in natural fiber-reinforced composites”, J Polym Environ, vol. 15, pp. 25-35, 2007.

H. Sharma, A Detail Chemistry of Coffee and Its Analysis. IntechOpen, 2020.

M. Y. Hashim, A. M. Amin, O. M. F. Marwah, M. H. Othman, M. R. Yunus, and N. C. Huat, “The effect of alkali treatment under various conditions on physical properties of kenaf fiber,” Journal of Physics: Conf. Series 914, 012030, 2017.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.