Investigating the high-impact deformation behavior of induced-nano precipitation hardened in718 alloy

DOI:

https://doi.org/10.55713/jmmm.v34i1.1855Keywords:

dynamic impact, flow stress, Hopkinson pressure bar, strain rate, superalloyAbstract

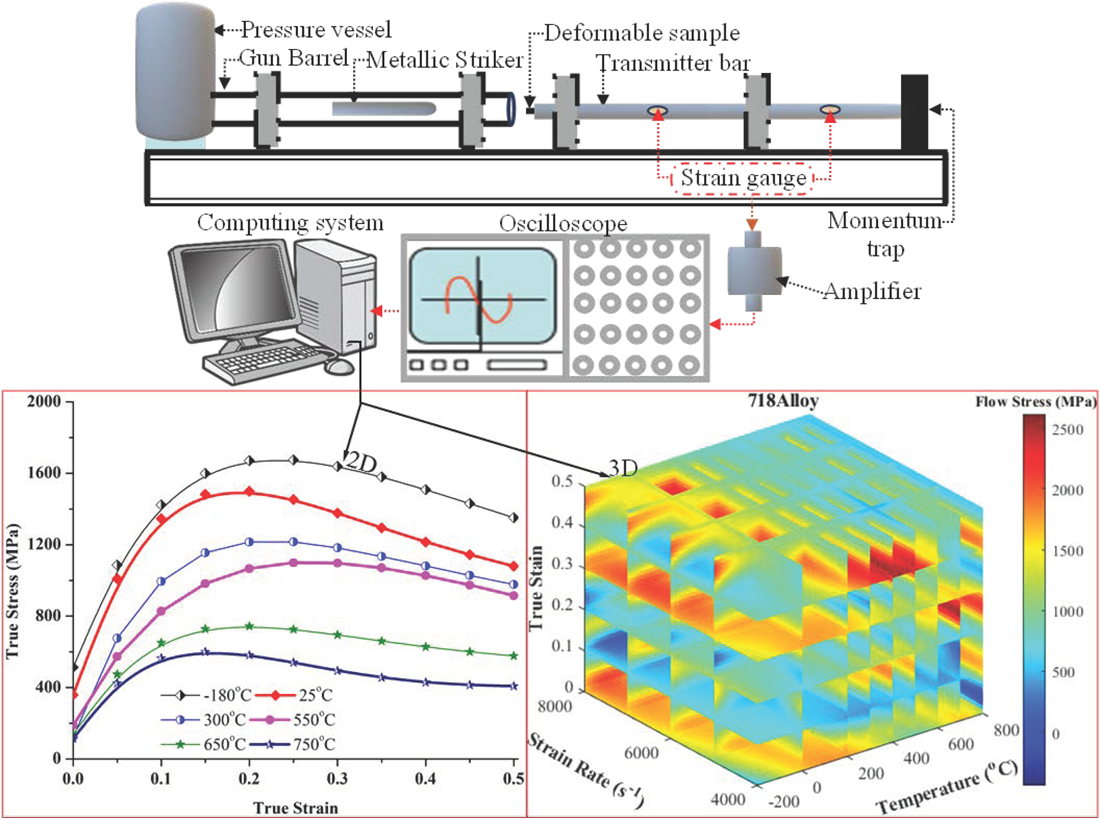

Superalloys are the preferred materials for modern high-rotational complex components due to their exceptional ability to maintain critical properties such as strength, oxidation/corrosion resistance, even under extreme temperatures and dynamic impacts. This study investigates the dynamic impact response of nanoprecipitation-hardened 718 alloy (NPH-718 alloy) under various loading conditions. The wrought nickel-based NPH-718 alloy was transformed into a nanostructured state through a precise heat treatment process involving controlled cooling rates (28℃∙s‒1 to 30℃∙s‒1). A mechanical compression test, leading to failure, was employed to assess the alloy's ability to withstand dynamic impacts. The compressive dynamic behavior of the alloy at high strain rates (4000 s‒1 to 7500 s‒1) and temperatures ranging from ‒180℃ to 750℃ was evaluated using a custom-built direct impact Hopkinson pressure bar apparatus. The flow data obtained for NPH-718 alloy exhibited sensitivity to thermally activated processes. Consequently, as the temperature increased at a constant high loading rate, both flow stress and adiabatic effect increased. Conversely, at a constant deformation temperature, the flow characteristics exhibited an increase as the loading rate decreased. This study establishes key trends in the flow stress, adiabatic effect, temperature, and the strain rate sensitivities of NPH-718 alloy, offering valuable insights for design and performance evaluation purposes. It underscores the significant influence of temperature and strain rate on the flow behavior of NPH-718 alloy, further solidifying its reliability in demanding applications.

Downloads

References

H. J. Penkalla, J. Wosika, and A. Czyrska-Filemonowicz, “Quantitative microstructural characterization of Ni-base superalloys.” Materials Chemistry and Physics, vol. 81, no. 2-3, pp. 417-423, 2003.

P. K. Sarkar, R. Ghosal, P. Rao, and V. G. Kumar, “High temperature low cycle fatigue behaviour of hot isostatically pressed superalloy Udimet 720 LI.” Materials at High Temperatures, vol. 27, pp. 295-300, 2010.

M. K. Sinha, R. Madarkar, S. Ghosh, and V. R. Paruchuri. “Some investigations in grindability improvement of Inconel 718 under ecological grinding,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 233, no. 3, pp.727-744, 2019.

Y. Wang, W. Z. Shao, L. Zhen, L. Yang, and X. M. Zhang, “Flow behaviour and microstructures of superalloy 718 during high temperature deformation,” Materials Science and Engineering: A, vol. 497, no. 1-2, pp. 479-486, 2008.

W-S. Lee, C-F. Lin, T-H. Chen, and H-W. Chen, “Dynamic impact response of inconel 718 alloy under low and high temperatures,” Materials Transactions, vol. 52, no. 9, pp. 1734-1740, 2011.

P. H. Pope, and J. E. Field, “Determination of strain in a dynamic compression test,” Journal of Physics E: Scientific Instruments, vol. 17, no. 9, pp. 817-820, 1984.

D. A. Gorham, P. H. Pope, and J. E. Field, “An improved method for compressive stress-strain measurements at very high strain rates.” Proceedings of the Royal Society A: Mathematical, Physical and Engineering sciences, vol. 438, no. 1902, pp. 153-170, 1992.

N. A. Fleck, M. P. F. Sutcliffe, S. Sivashanker, and X. J. Xin, “Compressive R-curve of a carbon fibre-epoxy matrix composite,” Composites Part B: Engineering, vol. 27, no. 6, pp. 531-541, 1996.

W. G. Ferguson, A. Kumar, and J. E. Dorn, “Dislocation damping in aluminum at high strain rates,” Journal of Applied Physics, vol. 38, 1863-1869, 1967.

A. Seeger, “The generation of lattice defects by moving dislocations, and its application to the temperature dependence of the flow-stress of F.C.C. crystals,” The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, vol. 46, no. 382, pp. 1194-1217, 1955.

K. Ogawa, and T. Nojima, “Impact strength of titanium alloys,” Journal of the Society of Materials Science, Japan, vol. 37, no. 421, 1171-1177, 1988.

W. S. Lee, and C. F. Lin, “High-temperature deformation behaviour of Ti6Al4V alloy evaluated by high strain-rate compression tests,” Journal of Materials Processing Technology, vol. 75, no. 1-3, pp. 127-136, 1998.

C. Y. Chiem, and J. Duffy, “Strain rate history effects and observations of dislocation substructure in aluminum single crystals following dynamic deformation,” Materials Science and Engineering, vol. 57, pp. 233-247, 1983.

L. Martin, “The Theory of the microscope - IV: The boundary-wave theory of image formation,” Proceedings of the Physical Society, Section B, vol. 62, no. 11, pp. 713-725, 1949.

O. A. Idowu, O. A. Ojo, and M. C. Chaturvedi, “Crack-free electron beam welding of Allvac 718Plus® superalloy,” Welding Journal, (Miami Fla), vol. 88, pp. 179s-187s, 2009.

J. Delorme, “Extension of a finite element model to 2D for the prediction of adiabatic shear bands,” M.Sc. Thesis in Mechanical Engineering at the University of Manitoba, Canada, Manitoba, 2012.

W.-S. Lee, C.-F. Lin, T.-H. Chen, and H.-W. Chen, “dynamic impact response of inconel 718 alloy under low and high temperatures,” Materials Transactions, vol. 52, no. 9, pp. 1734-1740, 2011.

J. T. (B.S.) Hammer, “Plastic deformation and ductile fracture of Ti-6Al-4V under various loading conditions,” M.Sc. Degree Thesis in Mechanical Engineering at the Ohio State University, 2012.

Y. Wang, W.Z. Shao, L. Zhen, L. Yang, and X. M. Zhang, “Flow behavior and microstructures of superalloy 718 during high temperature deformation,” Materials Science and Engineering A, vol. 497, pp. 479-486, 2008.

S.-T. Chiou, H.-L. Tsai, and W.-S. Lee, “Effects of strain rate and temperature on the deformation and fracture behaviour of titanium alloy,” Materials Transactions, vol. 48, no. 9, pp. 2525-2533, 2007.

C. I. Garcia, G. D. Wang, D. E. Camus, E. A. Loria, and A. J. DeArdo, “Hot deformation behavior of superalloy 718,” Proceedings of the international symposium on superalloys 7X3,625,706 and various derivatives, The Minerals, Metals and Materials Society, E. A. Loria, ed., pp. 293-302, 1994.

G.-Z. Quan, W.-Q. Lv, Y.-P. Mao, Y.-W. Zhang, and J. Zhou, “Prediction of flow stress in a wide temperature range involving phase transformation for as-cast Ti–6Al–2Zr–1Mo–1V alloy by artificial neural network,” Material Design, vol. 50, pp. 51-61, 2013.

H. Onovo, D. Esezobor, and M. Bodude, “Dynamic impact response of nanosized precipitates bearing waspaloy.” The Journal of Engineering Research [TJER], vol. 19 no. 2, pp. 180-189, 2023.

Y. Ashuach, Z. Rosenberg, and C. Avinadav, “Multi-step Kolsky bar loading of materials which fail by adiabatic shear banding,” Journal of Physics, Conference Series, 500, 2014.

D. MacDougall, “Determination of the plastic work converted to heat using radiometry,” Experimental Mechanics, vol. 40, no. 3, pp. 298-306, 2000.

C. Fichera, “High strain-rate and temperature behaviour of metals: Advanced testing and modelling,” Ph.D. Thesis, Politecnico di Torino (Polytechnic University of Turin), Italy, Turin, 2015.

W.-S. Lee, C.-Y. Liu, and T.-N. Sun, “Dynamic impact response and microstructural evolution of inconel 690 superalloy at elevated temperatures,” International Journal of Impact Engineering, vol. 32, pp. 210-223, 2005.

W.-S. Lee, and C. F. Lin, “Comparative study of the impact response and microstructure of 304L stainless steel with and without prestrain,” Metallurgical and Materials Transactions A, vol. 33, no. 9, pp. 2801-2810, 2002.

W.-S. Lee, T.-H. Chen, C.-F. Lin, and Z.-Y. Li, “Effects of strain rate and temperature on shear properties and fracture characteristics of 316L stainless steel,” Materials Transactions, vol. 53, no. 3, pp. 469-476, 2012.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.