The Effect of two-stage heat treatment on the microstructure and mechanical properties of high chrome austenitic manganese steel

DOI:

https://doi.org/10.55713/jmmm.v34i1.1898Keywords:

Austenitic manganese steel, Dispersed hardened austenite, Two-stage heatingAbstract

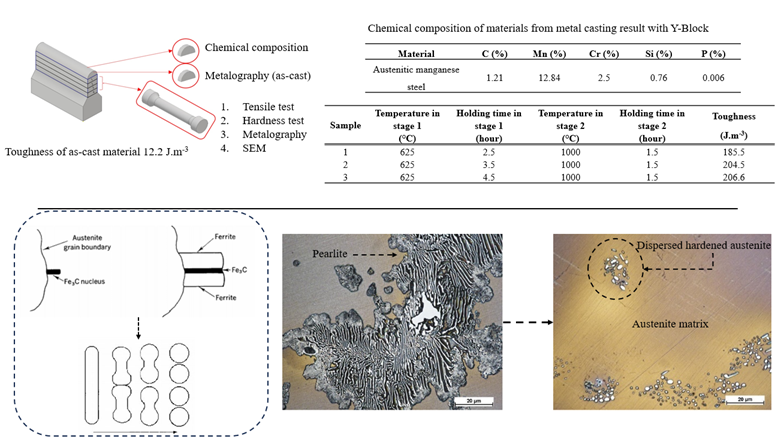

In this research, heat-treatment was used to determine changes in the microstructure and mechanical characteristics of austenitic manganese steel equivalent to ASTM A128-C. Carbide formed in as-cast conditions is transformed into dispersed hardened austenite to increase the toughness of the material because it can inhibit dislocation movement. Heat treatment is carried out in two heating stages. The first stage of heating was carried out at a temperature of 625°C with a holding time varying by 2.5, 3.5, and 4.5 h, and the second stage was carried out at a temperature of 1000°C with a constant holding time of 1.5 h. Microstructure observations were carried out to observe the structural morphology and carbide transformation in both the first and second stages of heating. Tensile and hardness tests were also carried out to determine the mechanical properties and their effect on two-stage heating. The research results show that the pearlite structure is formed in the first stage of heating with different lamella thicknesses. With the help of ImageJ software, the measured pearlite fraction was higher as the holding time increased in the first stage of heating. This affects the morphology of the carbide colonies formed in the second stage of heating. The higher the pearlite fraction, the more uniform the morphology of the carbide formed with round shapes that are more evenly distributed. These dispersed carbide colonies can increase the toughness of the material up to 17 times higher than the as-cast condition obtained through mechanical testing.

Downloads

References

S. Kuyucak, “Austenitic manganese steel castings,” in Metallograhy and Microstructures, ASM International, 2004, pp. 701-718.

N. Tsujimoto, “Casting practice of abrasion resistant austenitic manganese steel,” International Journal of Cast Metals Research, vol. 4, no. 2, pp. 62-77, 1979.

Z. Pei, R. Song, Q. Ba, and Y. Feng, “Dimensionality wear analysis: Three-body impact abrasive wear behavior of a martensitic steel in comparison with Mn13Cr2,” Wear, vol. 414, pp. 341-351, 2018.

P. N. Bidulya, and A. Troitsky, Технология Стальных Отливок. Steel Foundry Practice. Translated... by Anatoly Troitsky. Peace Publishers, 1965.

C. Chen, F. C. Zhang, F. Wang, H. Liu, and B. D. Yu, “Effect of N+ Cr alloying on the microstructures and tensile properties of Hadfield steel,” Materials Science and Engineering: A, vol. 679, pp. 95-103, 2017.

S. Alyaz, “Effects of heat treatment and chemical composition on microstructure and mechanical properties of hadfield steels,” Middle East Technical University, 2003.

S. Hosseini, and M. B. Limooei, “Optimization of heat treatment to obtain desired mechanical properties of high carbon Hadfield steels,” World Applied Sciences Journal, vol. 15, no. 10, pp. 1421-1424, 2011.

M. Azadi, A. M. Pazuki, and M. J. Olya, “The effect of new double solution heat treatment on the high manganese Hadfield steel properties,” Metallography, Microstructure, and Analysis, vol. 7, pp. 618-626, 2018.

B. Bal, “A study of different microstructural effects on the strain hardening behavior of Hadfield steel,” International Journal of Steel Structures, vol. 18, pp. 13-23, 2018.

P. H. Adler, G. B. Olson, and W. S. Owen, “Strain hardening of Hadfield manganese steel,” Metallurgical and Materials Transactions A, vol. 17, pp. 1725-1737, 1986.

H. Bhadeshia and R. Honeycombe, Steels: microstructure and properties. Butterworth-Heinemann, 2017.

Y. N. Dastur, and W. C. Leslie, “Mechanism of work hardening in Hadfield manganese steel,” Metallurgical transactions A, vol. 12, pp. 749-759, 1981.

B. Hutchinson, and N. Ridley, “On dislocation accumulation and work hardening in Hadfield steel,” Scripta Materialia, vol. 55, no. 4, pp. 299-302, 2006.

M. Lindroos, M. Apostol, V. Heino, K. Valtonen, A. Laukkanen, K. Holmberg, and V-T. Kuokkala“The deformation, strain hardening, and wear behavior of chromium-alloyed Hadfield steel in abrasive and impact conditions,” Tribol Lett, vol. 57, pp. 1-11, 2015.

C. Chen, B. Lv, H. Ma, D. Sun, and F. Zhang, “Wear behavior and the corresponding work hardening characteristics of Hadfield steel,” Tribol Int, vol. 121, pp. 389-399, 2018.

D. K. Subramanyam, G. W. Grube, and H. J. Chapin, “Austenitic manganese steel castings,” ASM Handbook., vol. 9, pp. 237-241, 1985.

A. Kamyabi-Gol, and M. Sheikh-Amiri, “Spheroidizing kinetics and optimization of heat treatment parameters in CK60 steel using taguchi robust design,” Journal of Iron and Steel Research International, vol. 17, no. 4, pp. 45-52, 2010.

G. Tęcza, and S. Sobula, “Effect of heat treatment on change microstructure of cast high-manganese hadfield steel with elevated chromium content,” Archives of Foundry Engineering, vol. 14, no. 3 spec, pp. 67-70, 2014.

I. El-Mahallawi, R. Abdel-Karim, and A. Naguib, “Evaluation of effect of chromium on wear performance of high manganese steel,” Materials Science and Technology, vol. 17, no. 11, pp. 1385-1390, 2001.

M. Sabzi, S. M. Far, and S. M. Dezfuli, “Effect of melting temperature on microstructural evolutions, behavior and corrosion morphology of Hadfield austenitic manganese steel in the casting process,” International Journal of Minerals, Metallurgy, and Materials, vol. 25, pp. 1431-1438, 2018.

J. R. Davis, K. M. Mills, and S. R. Lampman, “Metals handbook. Vol. 1. Properties and selection: irons, steels, and high-performance alloys,” ASM International, Materials Park, Ohio 44073, USA, 1990. 1063, 1990.

M. K. Banerjee, “2.8 Heat treatment of commercial steels for engineering applications,” 2017.

R. F. Mehl, and W. C. Hagel, “The austenite: pearlite reaction,” Progress in Metal Physics, vol. 6, pp. 74-134, 1956.

W. D. Callister Jr and D. G. Rethwisch, Callister’s materials science and engineering. John Wiley & Sons, 2020.

ASM Handbook, Vol 1, Properties and selection: irons, steels, and high performance alloys section: Publication information and contributors publication information and contributors authors and reviewers,” 2005.

W. S. Rasband, “US National Institutes of Health,” http://imagej. nih. gov/ij/, 2011.

M. Abbasi, S. Kheirandish, Y. Kharrazi, and J. Hejazi, “The fracture and plastic deformation of aluminum alloyed Hadfield steels,” Materials Science and Engineering: A, vol. 513, pp. 72-76, 2009.

D. Rittel, and I. Roman, “Tensile fracture of coarse-grained cast austenitic manganese steels,” Metallurgical transactions A, vol. 19, pp. 2269-2277, 1988.

L. Qian, X. Feng, and F. Zhang, “Deformed microstructure and hardness of Hadfield high manganese steel,” Mater Trans, vol. 52, no. 8, pp. 1623-1628, 2011.

J. Kowalska, J. Ryś, G. Cios, and W. Bednarczyk, “The effect of reduced temperatures on microstructure development in tensile tested high-manganese steel,” Materials Science and Engineering: A, vol. 767, p. 138406, 2019.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.