SBR elastomer response to renewable diesel blends: An experimental investigation

DOI:

https://doi.org/10.55713/jmmm.v34i4.2020Keywords:

Biodiesel, HVO, elastomer, swelling, polymer contentAbstract

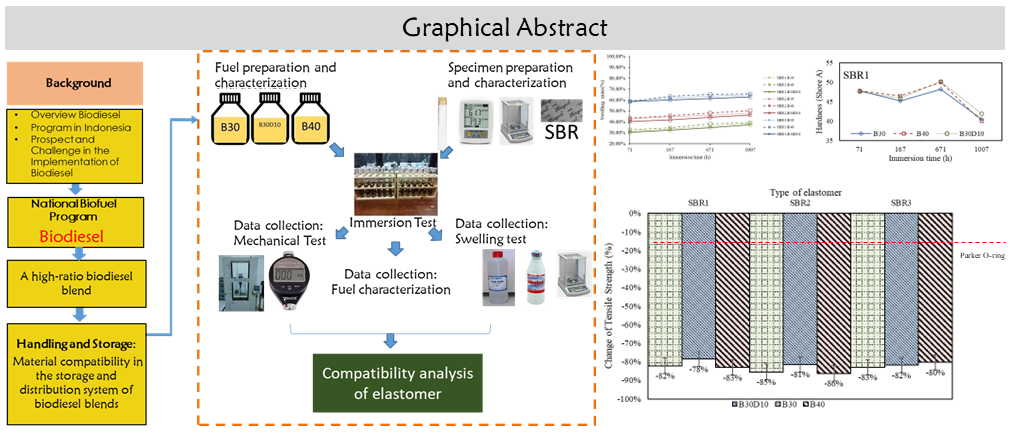

To investigate the impact of Styrene Butadiene Rubber (SBR) exposure to renewable fuels during handling and storage processes, compatibility tests were conducted on three different renewable fuel mixtures: 30% biodiesel, 40% biodiesel, and 30% biodiesel + 10% hydrogenated vegetable oil. These tests involved static immersion experiments conducted at room temperature for a duration of 1000 h, following the ASTM D471 standards. Before and after the immersion tests, the physical properties and visually assessed elastomers concentrations were investigated by varying the SBR content. Additionally, the post-immersion fuel properties were examined. The results showed that mass and volume swelling increased with the SBR-to-bound sulfur ratio. Enhanced mechanical strength was observed, particularly in cases with medium SBR content, which correlated with higher carbon black concentrations. The increasingly subtle morphological appearance was also captured via SEM. After immersion, fuel characterization showed that parameters such as acid number and water content remained stable without significant alterations.

Downloads

References

United Nation, “The Sustainable Development Goals Report,” 2022.

G. Knothe, and J. Van Gerpen, Biodiesel Handbook. AOCS Publishing, 2005. DOI: https://doi.org/10.1201/9781439822357

B. Norjannah, H. C. Ong, H. H. Masjuki, J. C. Juan, and W. T. Chong, “Enzymatic transesterification for biodiesel production: A comprehensive review,” RSC Advances, vol. 6, no. 65, pp. 60034-60055, 2016. DOI: https://doi.org/10.1039/C6RA08062F

M. Mittelbach, and C. Remschmidt, “Fuel stability,” in Biodiesel: The comprehensive handbook, 1st ed., Vienna (AUT): Boersedruck Ges.m.b.H, 2004, p. 148.

H. M. Mahmudul, F. Y. Hagos, R. Mamat, A. A. Adam, W. F. W. Ishak, and R. Alenezi, “Production, characterization and performance of biodiesel as an alternative fuel in diesel engines – A review,” Renewable and Sustainable Energy Reviews, vol. 72, no. November 2016, pp. 497-509, 2017. DOI: https://doi.org/10.1016/j.rser.2017.01.001

I. K. Reksowardojo, H. Setiapraja, R. Fajar, E. Wibowo, and D. Kusdiana, “An investigation of laboratory and road test of common rail injection vehicles fueled with B20 biodiesel,” Energies (Basel), vol. 13, no. 22, 2020. DOI: https://doi.org/10.3390/en13226118

D. Singh, K. A. Subramanian, and M. O. Garg, “Comprehensive review of combustion, performance and emissions characteristics of a compression ignition engine fueled with hydroprocessed renewable diesel,” Renewable and Sustainable Energy Reviews, vol. 81, no. July 2016, pp. 2947-2954, 2018. DOI: https://doi.org/10.1016/j.rser.2017.06.104

C. McCaffery, H. Zhu, C. M. S. Ahmed, A. Canchola, J. Y. Chen, L. Chengguo, K. C. Johnson, T. D. Durbin, Y-H. Lin, G. Karavalakis, “Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine,” Fuel, vol. 323, no. April, p. 124283, 2022. DOI: https://doi.org/10.1016/j.fuel.2022.124283

P. Zeman, V. Honig, M. Kotek, J. Taborsky, M. Obergruber, J. Marik, V. Hartova, and M. Pechout, “Hydrotreated vegetable oil as a fuel from waste materials,” Catalysts, vol. 9, no. 4, pp. 1-16, 2019. DOI: https://doi.org/10.3390/catal9040337

T. Hartikka, M. Kuronen, and K. Ulla, Technical Performance of HVO (Hydrotreated Vegetable Oil) in Diesel Engines, vol. 9. 2012. DOI: https://doi.org/10.4271/2012-01-1585

S. Mustika, and W. Wahyu Purwanto, “Multi-objective optimization of blending strategy of FAME, HVO, and petroleum diesel,” IOP Conference Series: Materials Science and Engineering, vol. 1143, no. 1, p. 012046, 2021. DOI: https://doi.org/10.1088/1757-899X/1143/1/012046

B. Rochmanto, H. Setiapraja, and M. Ekasari, “Kajian emisi dan konsumsi bahan bakar dalam penggunaan campuran bahan bakar biosolar pada kendaraan penumpang,” Rotor, vol. 13, no. 2, 2020. DOI: https://doi.org/10.19184/rotor.v13i2.19148

MEMR, “Surat Edaran - No.10.E/EK.05/DJE/2022-tentang implementasi penahapan pemanfaatan bahan bakar nabati jenis biodiesel sebagai campuran bahan bakar minyak jenis minyak solar dalam kerangka pembiayaan oleh BPDPKS,” 2022.

A. Syafiuddin, J. H. Chong, A. Yuniarto, and T. Hadibarata, “The current scenario and challenges of biodiesel production in Asian countries: A review,” Bioresource Technology Reports, vol. 12, no. November, p. 100608, 2020. DOI: https://doi.org/10.1016/j.biteb.2020.100608

X. F. Wei, Q. Meng, K. J. Kallio, R. T. Olsson, and M. S. Hedenqvist, “Ageing properties of a polyoxymethylene copolymer exposed to (bio) diesel and hydrogenated vegetable oil (HVO) in demanding high temperature conditions,” Polymer Degradation and Stability, vol. 185, Mar. 2021. DOI: https://doi.org/10.1016/j.polymdegradstab.2021.109491

A. S. M. A. Haseeb, T. S. Jun, M. A. Fazal, and H. H. Masjuki, “Degradation of physical properties of different elastomers upon exposure to palm biodiesel,” Energy, vol. 36, no. 3, pp. 1814-1819, 2011. DOI: https://doi.org/10.1016/j.energy.2010.12.023

K. A. Sorate, P. V. Bhale, and B. Z. Dhaolakiya, “A material compatibility study of automotive elastomers with high FFA based biodiesel,” Energy Procedia, vol. 75, pp. 105-110, 2015. DOI: https://doi.org/10.1016/j.egypro.2015.07.151

D. S. Maharani, A. R. Wimada, A. G. Arisanti, F. Karuana, H. Ghazidin, H. P. Putra, F. T. Pratiwi, and B. B. Restituta, “Influence of B30 palm-based biodiesel blends upon degradation of elastomers,” in IOP Conference Series: Earth and Environmental Science, Institute of Physics, 2022. DOI: https://doi.org/10.1088/1755-1315/1034/1/012052

T. Białecki, A. Sitkiewicz, B. Giemza, J. Sarnecki, M. Skolniak, and B. Gawron, “Compatibility of different automotive elastomers in paraffinic diesel fuel,” Applied Sciences (Switzerland), vol. 11, no. 23, 2021. DOI: https://doi.org/10.3390/app112311312

D. Bockey, “The significance and perspective of biodiesel production - A European and global view,” OCL - Oilseeds and fats, Crops and Lipids, vol. 26, 2019. DOI: https://doi.org/10.1051/ocl/2019042

A. Abdel-Hakim, S. A. el-Mogy, and A. I. Abou-Kandil, “Novel modification of styrene butadiene rubber/acrylic rubber blends to improve mechanical, dynamic mechanical, and swelling behavior for oil sealing applications,” Polymers and Polymer Composites, vol. 29, no. 9_suppl, pp. S959-S968, 2021. DOI: https://doi.org/10.1177/09673911211031351

A. Dorigato, D. Rigotti, and G. Fredi, “Recent advances in the devulcanization technologies of industrially relevant sulfur-vulcanized elastomers,” Advanced Industrial and Engineering Polymer Research, vol. 6, no. 3, pp. 288-309, 2023. DOI: https://doi.org/10.1016/j.aiepr.2022.11.003

EBTKE, Standar dan Mutu (Spesifikasi) Bahan Bakar Nabati (Biofuel) Jenis Biodiesel sebagai Bahan Bakar Lain yang Dipasarkan di Dalam Negeri D. EBTKE-ESDM Keputusan Dirjen EBTKE No.195.K/EK.05/DJE/2022 jo. Keputusan Dirjen EBTKE No.207.K/EK.05/DJE/2022. 2022. EBTKE, 2022.

EBTKE, Standar dan Mutu (Spesifikasi) Bahan Bakar Nabati Jenis Diesel Biohidrokarbon sebagai Bahan Bakar Lain yang Dipasarkan di Dalam Negeri. EBTKE, 2022.

Migas, Standar dan Mutu (Spesifikasi) Bahan Bakar Minyak Jenis Solar yang Dipasarkan di Dalam Negeri, SK Dirjen Migas No. 146.K/10/DJM/2020. Migas, 2020.

Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension, ASTM D412-16.

Parker O-Ring Handbook ORD 5700,” 2018. [Online]. Available: www.parkerorings.com

Standard Test Method for Rubber Property - Effect of Liquids, ASTM D471 − 16a.

Standard Test Method for Rubber Property-Durometer Hardness, ASTM D2240.

M. D. Stelescu, M. Sonmez, L. Alexandrescu, M. Nituica, D. F. Gurau, and M. Georgescu, “Structure and properties of blends based on vulcanized rubber waste and styrene–butadiene–styrene thermoplastic elastomer,” Journal of Rubber Research, vol. 25, no. 5, pp. 421-434, 2022. DOI: https://doi.org/10.1007/s42464-022-00187-y

B. Szadkowski, A. Marzec, and P. Rybiński, “Silane treatment as an effectiveway of improving the reinforcing activity of carbon nano-fibers in nitrile rubber composites,” Materials, vol. 13, no. 16, 2020. DOI: https://doi.org/10.3390/ma13163481

W. D. Callister and J. G. David Rethwisch, Materials Science and Engineering: An Introduction, Wiley, 2013.

J. Fröhlich, W. Niedermeier, and H. D. Luginsland, “The effect of filler-filler and filler-elastomer interaction on rubber reinforcement,” Composites Part A: Applied Science and Manufacturing, vol. 36, no. 4, pp. 449-460, 2005. DOI: https://doi.org/10.1016/j.compositesa.2004.10.004

I. M. Alarifi, “A comprehensive review on advancements of elastomers for engineering applications,” Advanced Industrial and Engineering Polymer Research, vol. 6, no. 4, pp. 451-464, 2023. DOI: https://doi.org/10.1016/j.aiepr.2023.05.001

J. Kruželák, A. Kvasničáková, and I. Hudec, “Peroxide curing systems applied for cross-linking of rubber compounds based on SBR,” Advanced Industrial and Engineering Polymer Research, vol. 3, no. 3, pp. 120-128, 2020. DOI: https://doi.org/10.1016/j.aiepr.2020.05.001

F. N. Linhares, H. L. Corrêa, C. N. Khalil, M. C. Amorim Moreira Leite, and C. R. Guimarães Furtado, “Study of the compatibility of nitrile rubber with Brazilian biodiesel,” Energy, vol. 49, no. 1, pp. 102-106, 2013. DOI: https://doi.org/10.1016/j.energy.2012.10.040

W. Trakarnpruk and S. Porntangjitlikit, “Palm oil biodiesel

synthesized with potassium loaded calcined hydrotalcite and effect of biodiesel blend on elastomer properties,” Renew Energy, vol. 33, no. 7, pp. 1558-1563, 2008. DOI: https://doi.org/10.1016/j.renene.2007.08.003

A. R.Wimada, M. D. Sholihah, F. Karuana, A. G. Arisanti, H. Ghazidin, and M. Chalid “Pengaruh bahan bakar campuran biodiesel berbahan dasar minyak sawit terhadap elastomer NBR,” Jurnal Rekayasa Material, Manufaktur dan Energi, vol. 6, no. 1, pp. 66-71, 2023. DOI: https://doi.org/10.30596/rmme.v6i1.12594

R. Gurani, and S. N. Kurbet, “Experimental investigation on compatibility of elastomeric materials with biodiesel,” International Journal of Engineering Research & Technology (IJERT), vol. 06, no. 16, 2018.

W. Balasooriya, B. Schrittesser, G. Pinter, and T. Schwarz, “Induced material degradation of elastomers in harsh environments,” Polymer Testing, vol. 69, pp. 107-115, 2018. DOI: https://doi.org/10.1016/j.polymertesting.2018.05.016

J. Hunicz, P. Krzaczek, M. Gęca, A. Rybak, and M. Mikulski, “Comparative study of combustion and emissions of diesel engine fuelled with FAME and HVO,” Combustion Engines, vol. 184, no. 1, pp. 72-78, 2021. DOI: https://doi.org/10.19206/CE-135066

F. Cataldo, O. Ursini, and G. Angelini, “Biodiesel as a plasticizer of a SBR-based tire tread formulation,” ISRN Polymer Science, vol. 2013, pp. 1-9, 2013. DOI: https://doi.org/10.1155/2013/340426

M. Sadeghalvaad, E. Dabiri, S. Zahmatkesh, and P. Afsharimoghadam, “Preparation and properties evaluation of nitrile rubber nano-composites reinforced with organo-clay, CaCO3, and SiO2 nano-fillers,” Polymer Bulletin, vol. 76, no. 8, pp. 3819-3839, 2019. DOI: https://doi.org/10.1007/s00289-018-2583-8

V. Marturano, P. Cerruti, and V. Ambrogi, “Polymer additives,” Physical Sciences Reviews, vol. 2, no. 6, pp. 1-22, 2019. DOI: https://doi.org/10.1515/psr-2016-0130

I.-S. Kim, B.-W. Lee, K.-S. Sohn, J. Yoon, and J.-H. Lee, “Characterization of the UV Oxidation of raw natural rubber thin film using image and FT-IR analysis,” Elastomers and Composites, vol. 51, no. 1, pp. 1-9, 2016. DOI: https://doi.org/10.7473/EC.2016.51.1.1

M. G. Aboelkheir, J. G. Lima Junior, R. D. Toledo Filho, F. G. Souza Junior, and C. Y. dos Santos Siqueira, “Thermo-oxidative degradation of vulcanized SBR: A comparison between ultraviolet (UV) and microwave as recovery techniques,” Journal of Polymer Research, vol. 28, no. 4, 2021. DOI: https://doi.org/10.1007/s10965-021-02497-y

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.