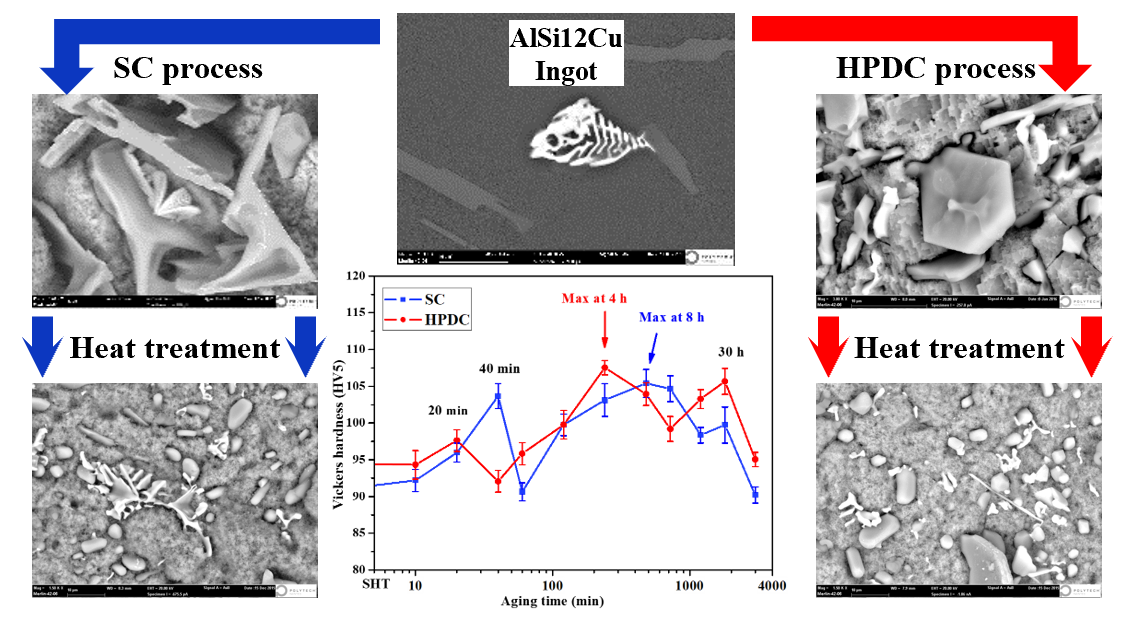

Influence of the casting processes and aging times on the microstructure and hardness of AlSi\(_{12}\)Cu cast alloys

DOI:

https://doi.org/10.55713/jmmm.v35i2.2220Keywords:

AlSi12Cu alloys, Microstructure, Aging, Precipitation, HardnessAbstract

The present study investigated the effects of the casting processes and aging times on the micro-structure and hardness of commercial AlSi12Cu alloys. The primary goal was to assess how various aging times affect the maximum hardness of the alloy and to evaluate the influence of cooling rates on hardness values obtained from sand casting (SC) and High-pressure die casting (HPDC). For both casting alloys, the solution heat treatment was performed at 540℃, followed by quenching. The alloys were then aged at 180℃ for various durations, ranging from 10 min to 50 h. The results reveal significant microstructural changes in the size and morphology of the eutectic silicon and intermetallic phases between the SC and HPDC. The α-Fe intermetallics predominantly exhibit a Chinese-script morphology in SC, whereas in HPDC, they are primarily present as polyhedral particles. The maximum hardness peak was observed at 8 h of aging in SC; in HPDC, it was achieved at only 4 h of aging. The results of the hardness and X-ray diffraction (XRD) analyses exhibit consistent trends, strong alignment, and good agreement with each other. The HPDC process, combined with heat treatment, significantly enhances the mechanical properties of cast aluminum alloys.

Downloads

References

ASM Handbook Committee, Materials Park, technical editor. ASM International, USA, Casting of Nonferrous Alloys, vol. 15. 2008. pp 1009-1018.

A. M. A. Mohamed, A. M. Samuel, F. H. Samuel, and H. W. Doty, “Influence of additives on the microstructure and tensile properties of near-eutectic Al-10.8%Si cast alloy,” Materials and Design, vol. 30, no. 10, pp. 3943-3957, 2009. DOI: https://doi.org/10.1016/j.matdes.2009.05.042

S. Beroual, Z. Boumerzoug, P. Paillard, and Y. Borjon-piron, “Comparative study on the microstructures and hardness of the AlSi10.6CuMg alloy produced by sand casting and high pressure die casting,” International Journal of Cast Metals Research, vol. 00, no. 00, pp. 1-22, 2019. DOI: https://doi.org/10.1080/13640461.2019.1603681

M. Okayasu, Y. Ohkura, S. Takeuchi, S. Takasu, H. Ohfuji, and T. Shiraishi, “A study of the mechanical properties of an Al-Si-Cu alloy (ADC12) produced by various casting processes,” Materials Science and Engineering A, vol. 543, pp. 185-192, 2012. DOI: https://doi.org/10.1016/j.msea.2012.02.073

M. T. Murray, and M. Murray, “High pressure die casting of aluminium and its alloys”, Woodhead Publishing Limited, vol. 1849. pp. 217-261, 2011. DOI: https://doi.org/10.1533/9780857090256.1.217

O. El Sebaie, A. M. Samuel, F. H. Samuel, and H. W. Doty, “The effects of mischmetal, cooling rate and heat treatment on the hardness of A319.1, A356.2 and A413.1 Al-Si casting alloys,” Materials Science and Engineering A, vol. 486, no. 1-2, pp. 241-252, 2008. DOI: https://doi.org/10.1016/j.msea.2007.09.011

C. L. Yang, Y. B. Li, B. Dang, H. Bin Lü, and F. Liu, “Effects of cooling rate on solution heat treatment of as-cast A356 alloy,” Transactions of Nonferrous Metals Society of China (English Edition), vol. 25, no. 10, pp. 3189-3196, 2015.

C. Chanmuang, W. Kongmuang, J. Pearce, and T. Chairuangsri, “Influence of casting techniques on hardness, tarnish behavior and microstructure of Ag-Cu-Zn-Si sterling silver jewelry alloys,” Journal of Metals, Materials and Minerals, vol. 22, no. 2, pp. 19-26, 2012.

S. G. Shabestari, and H. Moemeni, “Effect of copper and solidification conditions on the microstructure and mechanical properties of Al–Si–Mg alloys,” Journal of Materials Processing Technology, vol. 154, pp. 193-198, 2004. DOI: https://doi.org/10.1016/j.jmatprotec.2004.04.302

F. H. Samuel, A. M. Samuel, and H. Liu, “Effect of magnesium content on the ageing behaviour of water-chilled Al-Si-Cu-Mg-Fe-Mn (380) alloy castings,” Journal of Materials Science, vol. 30, no. 10, pp. 2531-2540, 1995. DOI: https://doi.org/10.1007/BF00362130

S. Shankar, and D. Apelian, “Die soldering: Mechanism of the interface reaction between molten aluminum alloy and tool steel,” Metallurgical and Materials Transactions B, vol. 33, no. 3, pp. 465–476, 2002. DOI: https://doi.org/10.1007/s11663-002-0057-7

L. F. Mondolfo. Aluminum alloys: structure and properties. London and Boston, Butterworth; 1976. DOI: https://doi.org/10.1016/B978-0-408-70932-3.50008-5

D. Apelian, and M. Makhlouf, “Casting Characteristics of Aluminum Die Casting Alloys,” FINAL REPORT, pp. 1-46, 2002.

S. A. Kori, M. S. Prabhudev, and T. M. Chandrashekharaiah, “Studies on the microstructure and mechanical properties of A356 alloy with minor additions of copper and magnesium,” Transactions of the Indian Institute of Metals, vol. 62, no. October, pp. 353-356, 2009. DOI: https://doi.org/10.1007/s12666-009-0052-7

I. Alfonso, C. Maldonado, G. Gonzalez, and A. Bedolla, “Effect of Mg content and solution treatment on the microstructure of Al-Si-Cu-Mg alloys,” Journal of Materials Science, vol. 41, no. 7, pp. 1945-1952, 2006. DOI: https://doi.org/10.1007/s10853-006-4494-y

J. A. Taylor, D. H. St John, J. Barresi, and M. J. Couper, “Influence of Mg content on the microstructure and solid solution chemistry of Al-7%Si-Mg casting alloys during solution treatment,” Materials Science Forum, vol. 331, pp. 277-282, 2000. DOI: https://doi.org/10.4028/www.scientific.net/MSF.331-337.277

S. Shivkumar, S. Ricci, C. Keller, and D. Apelian, “Effect of solution treatment parameters on tensile properties of cast aluminum alloys,” Journal of Heat Treating, vol. 8, no. 1, pp. 63-70, 1990. DOI: https://doi.org/10.1007/BF02833067

M. Samoshina, and N. Belov, “The features of phase composition and microstructure of eutectic piston alloys AlSi12CuMgNi and AlSi12Cu2MgNi. In: Weiland, H., Rol-lett, A.D., Cassada, W. A. (eds) ICAA13 Pittsburgh: Proceedings of the 13th International Conference on Aluminum Alloys. Springer, Cham, pp. 1245-1250, 2012. DOI: https://doi.org/10.1002/9781118495292.ch188

E. Sjölander, and S. Seifeddine, “The heat treatment of Al-Si-Cu-Mg casting alloys,” ournal of Materials Processing Technology, vol. 210, no. 10, pp. 1249-1259, 2010. DOI: https://doi.org/10.1016/j.jmatprotec.2010.03.020

P. Ouellet, and F. H. Samuel, “Effect of Mg on the ageing behaviour of Al-Si-Cu 319 type aluminium casting alloys,” Journal of Materials Science, vol. 34, pp. 4671-4697, 1999. DOI: https://doi.org/10.1023/A:1004645928886

R. X. Li, R. D. Li, Y. H. Zhao, L. Z. He, C. X. Li, H. R. Guan, and Z. Q. Hu “Age-hardening behavior of cast Al-Si base alloy,” Materials Letters, vol. 58, no. 15, pp. 2096-2101, 2004. DOI: https://doi.org/10.1016/j.matlet.2003.12.027

X. Dong, S. Amirkhanlou, and S. Ji, “Formation of strength platform in cast Al-Si-Mg-Cu alloys,” Scientific Reports, vol. 9, no. 1, pp. 1-11, 2019. DOI: https://doi.org/10.1038/s41598-019-46134-7

Material Properties Database, [Online]. Available: http://www. makeitfrom.com/material-properties/413.0-413.0-F-S12B-A04130-Cast-Aluminum

C. M. Gourlay, H. I. Laukli, and A. K. Dahle, “Defect band characteristics in Mg-Al and Al-Si high-pressure die castings,” Metallurgical and Materials Transactions A, vol. 38, no. 8, pp. 1833-1844, 2007. DOI: https://doi.org/10.1007/s11661-007-9243-1

G. Timelli, A. Fabrizi, S. Capuzzi, F. Bonollo, and S. Ferraro, “The role of Cr additions and Fe-rich compounds on microstructural features and impact toughness of AlSi9Cu3(Fe) diecasting alloys,” Materials Science and Engineering A, vol. 603, pp. 58-68, 2014. DOI: https://doi.org/10.1016/j.msea.2014.02.071

X. Cao, and J. Campbell, “The solidification characteristics of Fe-rich intermetallics in Al-11.5Si-0.4Mg cast alloys,” Metallurgical and Materials Transactions A, vol. 35 A, no. 5, pp. 1425-1435, 2004. DOI: https://doi.org/10.1007/s11661-004-0251-0

S. G. Shabestari, and S. Ghodrat, “Assessment of modification and formation of intermetallic compounds in aluminum alloy using thermal analysis,” Materials Science and Engineering A, vol. 467, no. 1-2, pp. 150-158, 2007. DOI: https://doi.org/10.1016/j.msea.2007.05.022

S. Seifeddine, E. Sjölander, and T. Bogdanoff, “On the role of copper and cooling rates on the microstructure, defect formations and mechanical properties of Al-Si-Mg alloys,” Materials Sciences and Applications, vol. 04, no. 03, pp. 171-178, 2013. DOI: https://doi.org/10.4236/msa.2013.43020

S. Beroual, Z. Boumerzoug, P. Paillard, and Y. Borjon-piron, “Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al-Si-Cu and Al- Si-Mg cast alloys,” Journal of Alloys and Compounds, vol. 784, pp. 1026-1035, 2019. DOI: https://doi.org/10.1016/j.jallcom.2018.12.365

E. Tillova, M. Chalupova, and L. Hurtalova, “Evolution of the Fe-rich phases in recycled AlSi9Cu3 cast alloy during solution treatment,” Journal Communications - Scientific Letters of the University of Žilina, vol. 12, no. 4, pp. 95-101, 2010. DOI: https://doi.org/10.26552/com.C.2010.4.95-101

M. T. A. El-khair, “Microstructure characterization and tensile properties of squeeze-cast AlSiMg alloys,” Materials Letters, vol. 59, pp. 894-900, 2005. DOI: https://doi.org/10.1016/j.matlet.2004.11.041

V. Ji, “Contribution à l’analyse par diffraction des rayons X de l’état microstructural et mécanique des matériaux hétérogènes (Contribution to X-ray diffraction analysis of the microstructural and mechanical state of heterogeneous materials), Thesis, Lille University, France, 2004.

Y. Du, Y.A. Chang, B. Huang, W. Gong, Z. Jin, H. Xu, Z. Yuan, Y. Liu, Y. He, and F.Y. Xie, “Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation,” Materials Science and Engineering A, vol 363, pp 140-151, 2003 DOI: https://doi.org/10.1016/S0921-5093(03)00624-5

C. L. Yang, Y. B. Li, B. Dang, H. Bin Lü, and F. Liu, “Effects of cooling rate on solution heat treatment of as-cast A356 alloy,” Transactions of Nonferrous Metals Society of China, vol. 25, no. 10, pp. 3189-3196, 2015. DOI: https://doi.org/10.1016/S1003-6326(15)63952-8

N. Roy, A. M. Samuel, and F. H. Samuel, “Porosity formation in AI-9 Wt Pet Si-3 Wt Pet Cu alloy systems: Metallographic observations,” Metallurgical and Materials Transactions A, vol. 27, no. 2, pp. 415-429, 1996. DOI: https://doi.org/10.1007/BF02648419

Downloads

Published

How to Cite

License

Copyright (c) 2025 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.