The effect of Fe-NiMnMo high entropy alloy electrode on enhancing the weldability and mechanical properties of railway steel 900A

DOI:

https://doi.org/10.55713/jmmm.v35i1.2292Keywords:

Railway steel 900A, Fe-NiMnMo electrode, The flux-cored arc welding (FCAW), Carbon equivalent (CE), High entropy alloyAbstract

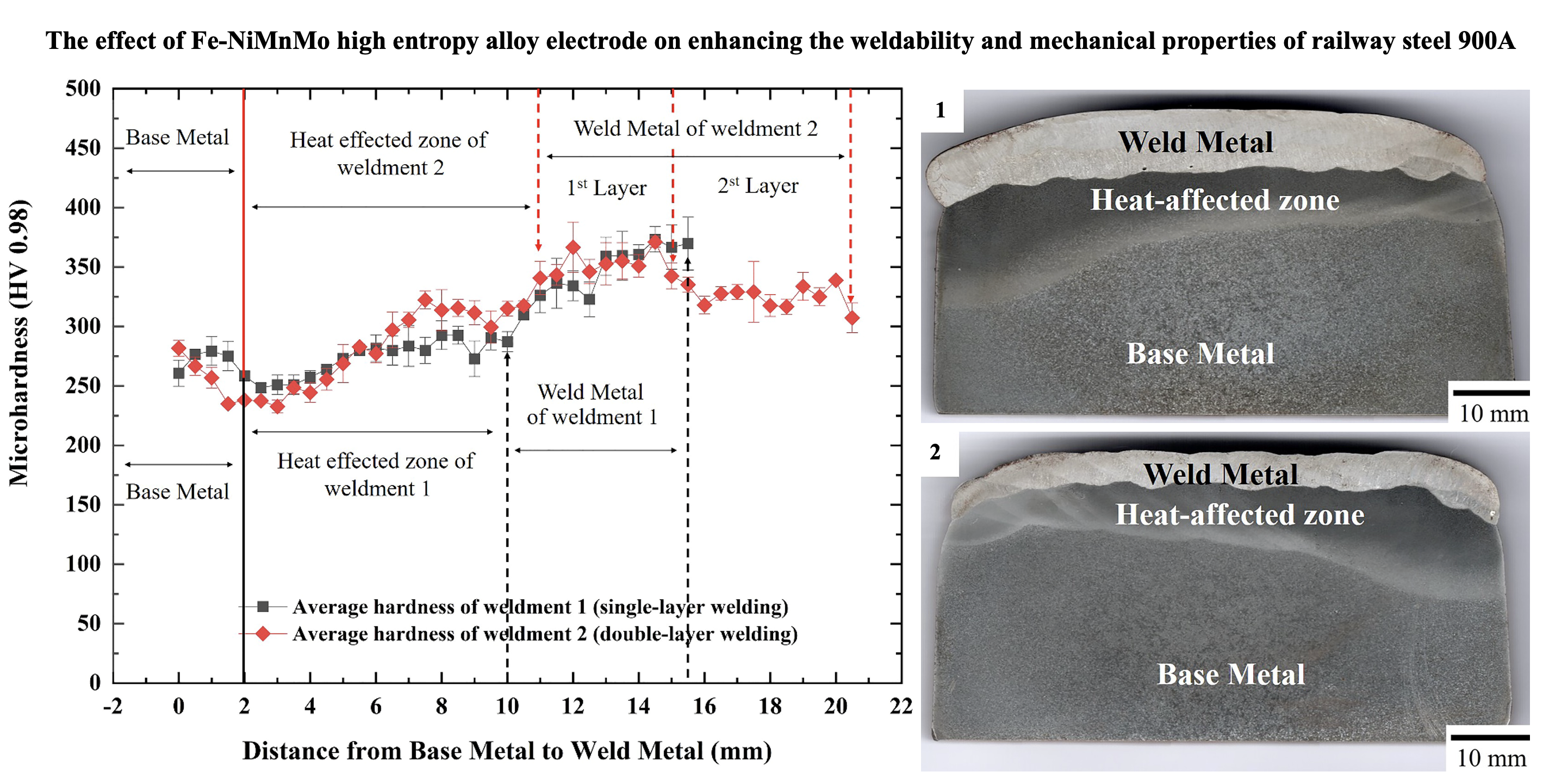

The rail transport system is essential for moving passengers and heavy goods over long distances, with steel 900A being a common material used for rail tracks in Thailand. Prolonged exposure to heavy loads and variable environmental conditions can lead to rail track damage known as "engine burn”, which results from friction between the train’s wheels and the rail. The flux-cored arc welding (FCAW) process is employed to repair these burns due to its use of readily available electrode wires and the efficiency of the repair. However, welding high-carbon steel like rail steel 900A poses challenges, such as a tendency to form martensite in the heat-affected zone and susceptibility to hydrogen cracking. The Fe-NiMnMo electrode has been identified as effective for hard-facing and repairing damaged rail surfaces. This study investigates the efficacy of the FCAW process using Fe-NiMnMo electrodes for repairing engine burns on rail steel 900A. Results demonstrate that the Fe-NiMnMo electrode strongly bonds with rail steel 900A. Multi-pass welding offers superior mechanical properties compared to single-pass welding, showing lower friction coefficients and wear rates. Detailed analysis using X-ray diffraction (XRD), energy dispersive spectroscopy (EDS), Vickers hardness testing, and high-temperature tribometry was studied to assess the mechanical properties and performance of the repaired rails.

Downloads

References

J. B. Akers, "Rail failures resulting from engine wheel burns, including effect of repairing such burns by oxyacetylene or electric welding" American Railway Engineering Association, vol.53, pp 894-898, 1952.

S. Kou, Welding Metallurgy. 2nd ed. New Jersey: A John Wiley & Sond, Inc., 2002. DOI: https://doi.org/10.1002/0471434027

B. Dahl, and B. Mogard, Repair of the rails on site by welding. Göthenburg: The ESAB group.

M. N. Saiful Akmal, and M. N. Wahab, "Characterization of UIC-54 rail head surface welded by hardfacing using flux-cored steel wire" In M. N Osman Zahid A. S. Abdul Sani, M. R. Mohamad Yasin, Z. Ismail, N. A. Che Lah, and F, Mohd, “Recent trends in manufacturing and materials towards industry 4.0, lecture notes in mechanical engineering”, Springer, Singapore, pp. 763-775, 2021. DOI: https://doi.org/10.1007/978-981-15-9505-9_68

H. Z. Oo, and P. Muangjunburee, “Improving microstructure and hardness of softening area at HAZ of thermite welding on rail running surface,” Materials Today communications, vol. 34, 10438, 2023. DOI: https://doi.org/10.1016/j.mtcomm.2023.105485

M. Alhassan, and Y. Bashiru, “Carbon equivalent fundamentals in evaluating the weldability of microalloy and low alloys steels,” World Journal of Engineering and Technology, vol. 9, pp. 782-792, 2021. DOI: https://doi.org/10.4236/wjet.2021.94054

T. Kasuya, and N. Yurioka, “Carbon equivalent and multiplying factor for hardenability of steel,” Weld Journal, vol. 72, pp. 263-268, 1993.

J. C. Lippold, Welding metallurgy and weldability. 1st ed., John Wiley & Sons, Inc or related company, 2014. DOI: https://doi.org/10.1002/9781118960332

Amarine Blog, Jan. 2024, “Weld carbon steel to stainless steel,” Amarin Blog. [Online]. Available:https://amarineblog.com/ 2019/05/31/stainless-steel-to-carbon-steel/.

CTF France Sauron. WPS welding procedure specification for translarail. Bondoufle Cedex France.

American National Standard, Recommended Practices for the Welding of Rails and Related Rail Components for Use by Rail Vehicles, AWS D15.2/D15.2M, 2013.

Standard practice for micro etching metals and alloys, ASTM E407-99, ASTM International, 1995.

Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, ASTM G 99-95a, ASTM International , 2000.

P. Muangjunburee, N. Poolsiri, S. Chaideesungnoen, A. Naultem, HZ Oo, and M. Kongpuang , “XRD observation on the weld metal of resurfaced rail steel,” ChiangMai Journal of Science, vol. 50, no. 4, pp. 1-11, 2023.

O. Crisanand, and A. D Crisan, “Phase transformation and exchange bias effects in mechanically alloyed Fe/magnetite powders,” Journal of Alloys and Compounds, vol. 509, pp. 6522-6527, 2011. DOI: https://doi.org/10.1016/j.jallcom.2011.03.147

K. Kiraga, E. Szychta, and L. Szychta L, “Determination of rail steel’s phase composition by mean of X-ray diffraction analysis,” Institute of Electrical and Electronics Engineers, pp. 316-318, 2012. DOI: https://doi.org/10.1109/ELEKTRO.2012.6225611

L. Keller, J. Rask, P. Buseck, Arizona State University, Tempe, Arizona, USA., ICDD Grant-in-Aid, (1986)

D. Smith Penn State University, University Park, Pennsylvania, USA., ICDD Grant-in-Aid, (1976)

Steel Express Limited. “Steel hardness conversion table,” [Online]. Available:https://www.steelexpress.co.uk/steel-hardness conversion.html

H. Boer, and H. Masumoto, “Niobium in rail steel,” Proceedings of the International Symposium Niobium, Orlando, USA, pp. 1-24, 2001.

R. R. Porcaro, G. L. Faria, L. B. Godefroid, G. R. Apolonio, L. C. Candido, and E. S. J. Pinto, “Microstructure and mechanical properties of a flash butt welded pearlitic rail,” Journal of materials processing technology, vol. 270, pp. 20-27, 2019. DOI: https://doi.org/10.1016/j.jmatprotec.2019.02.013

E. Pereloma, and D. V. Edmonds, Phase transformation in steels: Fundamentals and diffusion-Controlled Transformations. Woodhead Publishing Limited, 2012. DOI: https://doi.org/10.1533/9780857096104

Downloads

Published

How to Cite

License

Copyright (c) 2025 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.