Production of autoclaved lightweight concretes using pottery stone and bagasse ash

DOI:

https://doi.org/10.55713/jmmm.v33i2.1601Keywords:

Autoclaved lightweight concrete, Pottery stone, Bagasse ash, AluminiumAbstract

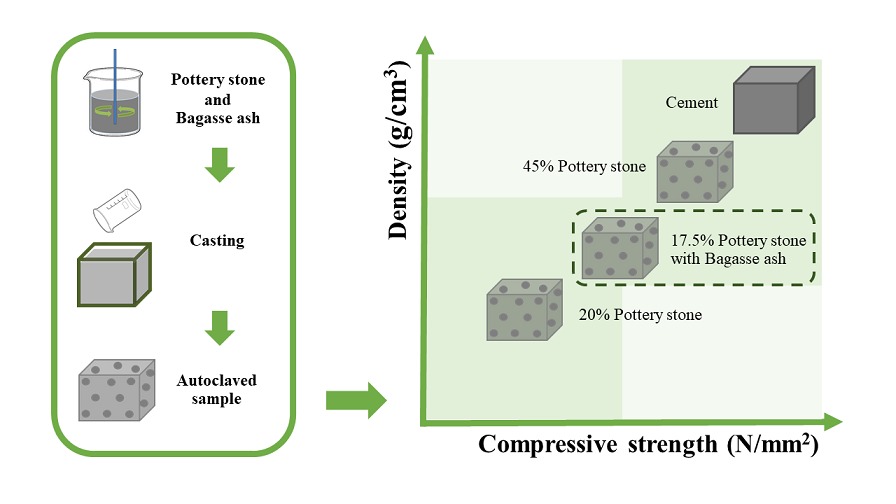

This study investigated the influence of pottery stone and bagasse ash on the mechanical features of autoclaved lightweight concrete. Pottery stone is a natural resource of igneous rock weathering commonly exists with white clay, feldspar and limestone. This raw material is mainly composed of quartz and mica that has been used for the production of ceramic products. Bagasse ash is a waste product of the sugar refining process that causes serious environmental pollution. Pottery stone and bagasse ash waste were physically characterized and partially substituted by the weight of cement in lightweight concrete with the addition of aluminium powder at a certain amount. The use of aluminium powder showed a positive effect on the porosity of lightweight bodies. Compressive strength, density and thermal conductivity were determined. Pottery stone can be used as a natural pozzolan for the production of lightweight concrete. Lightweight concrete manufactured with 17.5% pottery stone and 17.5% bagasse ash showed low density and good compressive strength. Autoclaved lightweight concrete is considered an economy in the consumption of pottery stone and bagasse ash waste as cement replacement, therefore enhancing the possibility of its reuse in a sustainable way.

Downloads

References

M. Norouzi, M. Chàfer, L. F. Cabeza, L. Jiménez, and D. Boer, "Circular economy in the building and construction sector: A scientific evolution analysis," Journal of Building Engineering, vol. 44, p. 102704, 2021.

M. Ghufran, K. I. A. Khan, F. Ullah, A. R. Nasir, A. A. Al Alahmadi, A. N. Alzaed, and M. Alwetaishi, "Circular economy in the construction Industry: A Step towards sustainable development," Building, vol. 12, no. 7, pp. 1-26, 2022.

S. Thiansem, W. Schulle, K. Kaew-kam-nerd, P. Thavornyutikarn and S. Phanichphant, "Quality improvement of Lampang clay for porcelain bodies," ScienceAsia, vol. 28, pp. 145-152, 2002.

P. Sirilar, N. Srisukhumbowornchai, P. Thanakijkasem, S. Sirisoonthorn, and G. Klein, "Influence of Lampang pottery stone: local materials in Thailand on C-Q-F ratio, key properties, mullite formation and glaze-body fit of vitreous ceramic sanitary ware," Journal of the Australian Ceramic Society, vol. 55, pp. 1153-1160, 2019.

P. To-on, P. Witchayaphong, and J. Pansuwan, "A Study of the properties of bagasse ash for the possibility in making light weight block," RMUTI Journal Science and Technology, vol. 9, no. 3, pp. 1-10, 2016.

M. Maragatham, "Experimental study on bagasse ash and its strength on M25 & M30 grade concrete," International Research Journal of Engineering and Technology, vol. 5, no. 12, pp. 884-890, 2018.

N. Chusilp, C. Jaturapitakkul and K. Kiattikomol, "Utilization of bagasse ash as a pozzolanic material in concrete," Construction and Building Materials, vol. 23, no. 11, pp. 3352-3358, 2009.

Y. Yang, B. Chen, W. Zeng, Y. Li, Q. Chen, W. Guo, H. Wang, and Y. Chen, "Utilization of completely recycled fine aggregate for preparation of lightweight concrete partition panels," International Journal of Concrete Structures and Materials, vol. 15, no. 32, pp. 2-11, 2021.

M. Bediako, and A. O. Rimpong, "Alternative binders for increased sustainable construction in Ghana—A guide for building professionals," Materials Sciences and Applications, vol. 4, pp. 20-28, 2013.

S. Kashef-Haghighi, Y. Shao, and S. Ghoshal, "Mathematical modeling of CO2 uptake by concrete during accelerated carbonation curing," Cement and Concrete Research, vol. 67, pp. 1-10, 2015.

A. J. Hamad, "Materials, production, properties and application of aerated lightweight concrete: review," International Journal of Materials Science and Engineering, vol. 2, no. 2, pp. 152-157, 2014.

A. H. Niknamfar, and S. Eesapoor, "Generating a structural lightweight concrete," presented at the 3rd International Conference of Science and Engineering in the Technology Era; Denmark Copenhagen, Nov. 30, 2017.

A. Apiwaranuwat, P. Kitratporn, K. Chuangcham, and T. Punmatharith, "Use of sugarcane bagasse ash as raw material in production of autoclaved lightweight concrete," Advanced Materials Research, vol. 652-654, pp. 1242-1246, 2013.

Cellular lightweight concrete blocks using preformed foam, TIS 2601-2556, Thai Industrial Standard Institute, Ministry of Industry, Sep. 25, 2013.

M. D. Jackson, J. Moon, E. Gotti, R. Taylor, S. R. Chae, M. Kunz, A.-H. Emwas, C. Meral, P. Guttmann, P. Levitz, H.-R. Wenk, and P. J. M. Monteiro, "Material and elastic properties of Al-tobermorite in ancient roman seawater concrete," Journal of the American Ceramic Society, vol. 96, no. 8, pp. 2598-2606, 2013.

L. Galvánková, J. Másilko, T. Solný, and E. Štepánková, “Tobermorite synthesis under hydrothermal conditions,“ Procedia Engineering, vol. 151, pp. 100-107, 2016.

C. Habsya, K. Diharjo, P. Setyono, and P. Satwiko, " Physical, mechanical and thermal properties of lightweight foamed concrete with fly ash," IOP Conf. Series: Materials Science and Engineering, vol. 420, no. 11, pp. 012062, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.