Thermal and mechanical evaluation of natural fibers reinforced gypsum plaster composite

DOI:

https://doi.org/10.55713/jmmm.v33i1.1669Keywords:

Natural fibers, Gypsum, Thermal conductivity, Microstructure, Compressive strengthAbstract

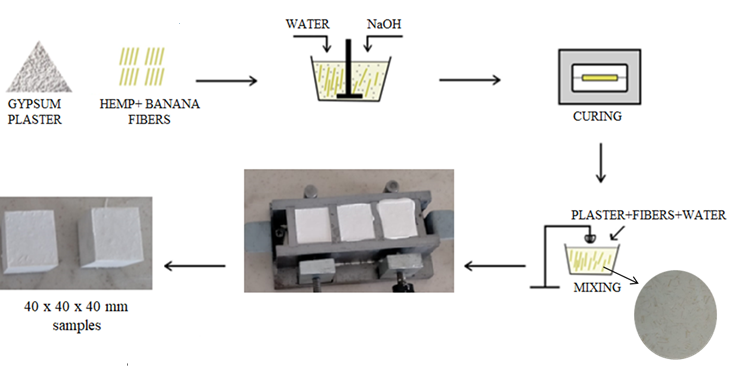

Many problems such as the increase in the world population, global drought, and greenhouse gases have caused materials used in industries to be reconsidered. This is how the concept of green composite material emerged. Using natural fibers to obtain such materials is important in terms of sustainability. This study is aimed to use hemp fiber and banana fiber as natural fiber additives in the gypsum composite to produce green bio-composite. Natural fibers are chemically modified with 5% NaOH solution. In this way, a good fiber/matrix interface interaction is provided. The composite hardness test result of 5 wt% HB fiber added sample is obtained as 50.4. Compared to the control plaster sample test result, which is 53.6, a slight decrease can be seen. However, it is observed that the fibers held the structure together and sopped the crack propagation. The increase in the porous structure with fiber addition caused a decrease in the thermal conductivity of the composite. Comparing thermal conductivity result of 5 wt% HB fiber reinforced gypsum composite (0.131 W⸳mK-1) with respect to pure gypsum result (0.237 W⸳mK-1), it gave a promising result as an insulation material.

Downloads

References

S. Awang Ngah, B. Dams, M. P. Ansell, J. Stewart, R. Hempstead, and R. Ballet, “Structural performance of fibrous plaster. Part 1: Physical and mechanical properties of hessian and glass fiber reinforced gypsum composites,” Construction and Building Materials, vol. 259, p. 120396, 2020

J. B. Kengoh, E. Peter Etape, B. Victorine Namondo, J, Foba-Tendo, Y. R. Nafu, and B. E. Fabien, “Influence of urena lobata fiber treatment on mechanical performance development in hybrid urena lobata: fiber/gypsum plaster composites,” Advances in Materials Science and Engineering, vol. 2021, pp. 1-10, 2021.

L. Shiroma, G. Camarini, and A. L. Beraldo, “Effect of wood particle treatment on the properties of gypsum plaster pastes and composites,” Matéria (Rio de Janeiro), vol. 21, no. 4, pp. 1032-1044, 2016.

K. Zając, M. Janus, and A. W. Morawski, “Improved self-cleaning properties of photocatalytic gypsum plaster enriched with glass fiber,” Materials (Basel, Switzerland), vol. 12, no. 3, 2019.

M. A. Ali, and F. J. Grimer, “Mechanical properties of glass fiber-reinforced gypsum,” Journal of Materials Science, vol. 4, no. 5, pp. 389-395, 1969.

M. Y. Durgun, “Effect of wetting-drying cycles on gypsum plasters containing ground basaltic pumice and polypropylene fibers,” Journal of Building Engineering, vol. 32, p. 101801, 2020.

A. Wang, S. Cao, and E. Yilmaz, “Effect of height to diameter ratio on dynamic characteristics of cemented tailings backfills with fiber reinforcement through impact loading,” Construction and Building Materials, vol. 322, p. 126448, 2022

A. Wang, S. Cao, and E. Yilmaz, “Influence of types and contents of nano cellulose materials as reinforcement on stability performance of cementitious tailings backfill,” Construction and Building Materials, vol. 344, p. 128179, 2022.

O. Onuaguluchi, and N. Banthia, “Plant-based natural fiber reinforced cement composites: A review,” Cement and Concrete Composites, vol. 68, pp. 96-108, 2016.

J. Zach, J. Peterková, and M. Sedlmajer, “Hygrothermal behavior of thermal insulating material based on technical hemp and its application in construction,” Advanced Materials Research, 860-863, pp. 1223-1226, 2013.

X. Zhou, H. Saini, and G. Kastiukas, “Engineering properties of treated natural hemp fiber-reinforced concrete,” Frontiers in Built Environment, vol. 3, 2017.

A. P. Fantilli, D. Jóźwiak-Niedźwiedzka, and P. Denis, “Bio-fibers as a reinforcement of gypsum composites,” Materials (Basel, Switzerland), vol. 14, no. 17, 2021.

M. Vailati, M. Mercuri, M. Angiolilli, and A. Gregori, “Natural-fibrous lime-based mortar for the rapid retrofitting of heritage masonry buildings,” Fibers, vol. 9, no. 11, p. 68, 2021.

N. G. Ozerkan, B. Ahsan, S. Mansour, and S. R. Iyengar, “Mechanical performance and durability of treated palm fiber reinforced mortars,” International Journal of Sustainable Built Environment, vol. 2, no. 2, pp. 131-142, 2013.

X. Y. Ding, G. Y. Tian, and A. M. Ge, “Comparative study on properties of different straw fiber cement composites,” IOP Conference Series: Materials Science and Engineering, vol. 479, p. 12097, 2019.

N. Belayachi, D. Hoxha, and M. Slaimia, “Impact of accelerated climatic aging on the behavior of gypsum plaster-straw material for building thermal insulation,” Construction and Building Materials, vol. 125, pp. 912-918, 2016.

R. Gellert, “Natural fiber and fiber composite materials for insulation in buildings,” in Materials for Energy Efficiency and Thermal Comfort in Buildings, pp. 229-256, Elsevier, 2010.

V. K. Mathur, “Composite materials from local resources,” Construction and Building Materials, vol. 20, no. 7, pp. 470-477, 2006.

Z. D. Gao, and G. Z. Li, “Effect of Straw Fiber Modification on Performance of Gypsum Composite,” Advanced Materials Research, 168-170, pp. 1455-1458, 2010.

B. Çomak, A. Bideci, and Ö. Salli Bideci, “Effects of hemp fibers on characteristics of cement based mortar,” Construction and Building Materials, vol. 169, pp. 794-799, 2018.

A. Donatelli, D. Cuna, M. A. Tagliente, M. L. Protopapa, A. Mevoli, P. Aversa, C. Blasi, L. Capodieci, and V. A. M. Luprano, “Effect of treatments on the aging behaviour of hemp fibers for building construction in the Mediterranean Area,” Journal of Building Engineering, vol. 11, pp. 37-47, 2017.

M. Charai, H. Sghiouri, A. Mezrhab, and M. Karkri, “Thermal insulation potential of non-industrial hemp (Moroccan cannabis sativa L.) fibers for green plaster-based building materials,” Journal of Cleaner Production, vol. 292, p. 126064, 2021.

F. Iucolano, B. Liguori, P. Aprea, and D. Caputo, “Evaluation of bio-degummed hemp fibers as reinforcement in gypsum plaster,” Composites Part B: Engineering, vol. 138, pp. 149-156, 2018.

F. Pacheco-Torgal, and S. Jalali, “Cementitious building materials reinforced with vegetable fibers: A review,” Construction and Building Materials, vol. 25, no. 2, pp. 575-581, 2011.

Z. Li, X. Wang, and L. Wang, “Properties of hemp fiber reinforced concrete composites,” Composites Part A: Applied Science and Manufacturing, vol. 37, no. 3, pp. 497-505, 2006.

B. T. Węcławski, M. Fan, and D. Hui, “Compressive behaviour of natural fiber composite,” Composites Part B: Engineering, vol. 67, pp. 183-191, 2014.

B. A. Akinyemi and C. Dai, “Development of banana fibers and wood bottom ash modified cement mortars,” Construction and Building Materials, vol. 241, p. 118041, 2020.

M. Mostafa and N. Uddin, “Effect of banana fibers on the compressive and flexural strength of compressed earth blocks,” Buildings, vol. 5, no. 1, pp. 282-296, 2015.

R. B. Mugume, A. Karubanga, and M. Kyakula, “Impact of addition of banana fibers at varying fiber length and content on mechanical and microstructural properties of concrete,” Advances in Civil Engineering, vol. 2021, pp. 1-15, 2021.

Turkish Standard, “Gypsum binders and gypsum plasters - Part 1: Definitions and requirements,” 2/12/2009, TS EN 13279-1.

S. KAYA and E. ONER, “Production, characteristics and applications of hemp fibers in textile industry,” The Journal of Graduate School of Natural and Applied Sciences of Mehmet Akif Ersoy University, vol. 11, no. 1, pp. 108-123, 2020.

A. K. Mohanty, M. Misra, and G. Hinrichsen, “Biofibers, biodegradable polymers and biocomposites: An overview,” Macromolecular Materials and Engineering, 276-277, no. 1, pp. 1-24, 2000.

A. Bledzki, “Composites reinforced with cellulose based fibers,” Progress in Polymer Science, vol. 24, no. 2, pp. 221-274, 1999.

X. Li, L. G. Tabil, and S. Panigrahi, “Chemical Treatments of natural fiber for use in natural fiber-reinforced composites: A review,” Journal of Polymers and the Environment, vol. 15, no. 1, pp. 25-33, 2007.

M. M. Kabir, H. Wang, K. T. Lau, F. Cardona, and T. Aravinthan, “Mechanical properties of chemically-treated hemp fiber reinforced sandwich composites,” Composites Part B: Engineering, vol. 43, no. 2, pp. 159-169, 2012.

M. Le Troedec, D. Sedan, C. Peyratout, J. P. Bonnet, A. Smith, R. Guinebretiere, V. Gloaguen, and P. Krausz, “Influence of various chemical treatments on the composition and structure of hemp fibers,” Composites Part A: Applied Science and Manufacturing, vol. 39, no. 3, pp. 514-522, 2008.

S. Kalia, B. S. Kaith, and I. Kaur, “Pretreatments of natural fibers and their application as reinforcing material in polymer composites-A review,” Polymer Engineering & Science, vol. 49, no. 7, pp. 1253-1272, 2009.

L. Y. Mwaikambo, and M. P. Ansell, “Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization,” Journal of Applied Polymer Science, vol. 84, no. 12, pp. 2222-2234, 2002.

D. Sedan, C. Pagnoux, A. Smith et al., “Mechanical properties of hemp fiber reinforced cement: Influence of the fiber/matrix interaction,” Journal of the European Ceramic Society, vol. 28, no. 1, pp. 183-192, 2008.

L. Y. Mwaikambo, N. Tucker, and A. J. Clark, “Mechanical properties of hemp-fiber-reinforced euphorbia composites,” Macromolecular Materials and Engineering, vol. 292, no. 9, pp. 993-1000, 2007.

M. Le Troëdec, C. S. Peyratout, A. Smith, and T. Chotard, “Influence of various chemical treatments on the interactions between hemp fibers and a lime matrix,” Journal of the European Ceramic Society, vol. 29, no. 10, pp. 1861-1868, 2009.

N. Sgriccia, M. C. Hawley, and M. Misra, “Characterization of natural fiber surfaces and natural fiber composites,” Composites Part A: Applied Science and Manufacturing, vol. 39, no. 10, pp. 1632-1637, 2008.

H. Shah, B. Srinivasulu, and S. C. Shit, “Influence of banana fiber chemical modification on the mechanical and morphological

properties of woven banana fabric/unsaturated polyester resin composites,” Polymers from Renewable Resources, vol. 4, no. 2, pp. 61-84, 2013.

A. Parre, B. Karthikeyan, B. Alagappan, and R. Udhayasankar, “Investigation of chemical, thermal and morphological properties of untreated and NaOH treated banana fiber,” Materials Today: Proceedings, vol. 22, pp. 347-352, 2020.

K. J Vishnu Vardhini, “Effect of alkali treatment on physical properties of banana fiber,” Indian Journal of Fiber & Textile Research, vol. 44, pp. 459-465, 2019.

W. D. Callister, Materials science and engineering: An introduction / William D. Callister, jr. Solutions manual, Wiley, New York, Chichester, 1991.

P. Zak, T. Ashour, A. Korjenic, S. Korjenic, and W. Wu, “The influence of natural reinforcement fibers, gypsum and cement on compressive strength of earth bricks materials,” Construction and Building Materials, vol. 106, pp. 179-188, 2016.

F. Iucolano, B. Liguori, P. Aprea, and D. Caputo, “Thermo-mechanical behaviour of hemp fibers-reinforced gypsum plasters,” Construction and Building Materials, vol. 185, pp. 256-263, 2018.

K. Suresh Babu, and C. Ratnam, “Mechanical and thermophysical behavior of hemp fiber reinforced gypsum composites,” Materials Today: Proceedings, vol. 44, pp. 2245-2249, 2021.

H. T. ŞAHİN, and E. CAM, “Properties of gypsum boards made with cedrus tree (cedrus libani) components. part 1. physical and mechanical properties,” Bartın Orman Fakültesi Dergisi, p. 1, 2022.

M. Álvarez, D. Ferrández, C. Morón, and E. A. Sanchez., “Characterization of a new lightened gypsum-based material reinforced with fibers,” Materials (Basel, Switzerland), vol. 14, no. 5, 2021.

Turkish Standard, “Gypsum binders and gypsum plasters - Part 2: Test methods,” 4/29/2014, TS EN 13279-2.

Y. A. Çengel, and A. J. Ghajar, Heat and mass transfer: Fundamentals & applications/Yunus A. Çengel, Afshin J. Ghajar, McGraw-Hill, New York, 2011.

R. Stapulionienė, S. Vaitkus, S. Vėjelis, and A. Sankauskaite, “Investigation of thermal conductivity of natural fibers processed by different mechanical methods,” International Journal of Precision Engineering and Manufacturing, vol. 17, no. 10, pp. 1371-1381, 2016.

A. Braiek, M. Karkri, A. Adili, L. Ibos, and S. B. Nasrallah, “Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building,” Energy and Buildings, vol. 140, pp. 268-279, 2017.

R. A. J. Malenab, J. P. S. Ngo, and M. A. B. Promentilla, “Chemical treatment of waste abaca for natural fiber-reinforced geopolymer composite,” Materials (Basel, Switzerland), vol. 10, no. 6, 2017.

Turkish Standard, “Reaction to fire tests Ignitability of products subjected to direct impingement of flame - Part 2: Single-flame source test: TS EN ISO 11925-2,”.

B. Baghaei, M. Skrifvars, M. Salehi, T. Bashir, M. Rissanen, and P. Nousianien, “Novel aligned hemp fiber reinforcement for structural biocomposites: Porosity, water absorption, mechanical performances and viscoelastic behaviour,” Composites Part A: Applied Science and Manufacturing, vol. 61, pp. 1-12, 2014.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.