Fabrication of granular foam glass aggregates from soda lime silicate glass waste

DOI:

https://doi.org/10.55713/jmmm.v33i4.1671Keywords:

Foam glass, Granulation, Lightweight, SinteringAbstract

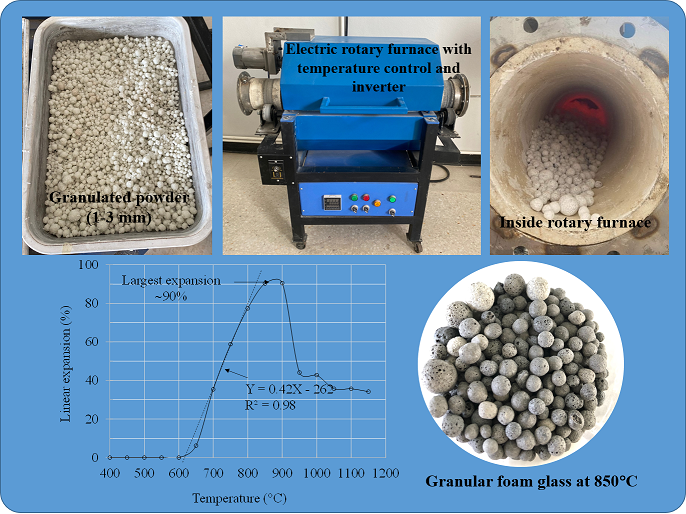

Granular foam glass aggregates were fabricated from a soda lime silicate glass waste which utilized crude glycerol as a foaming agent and sodium silicate as a binder. The granulation and the foaming process were carried out by a granulator and an electric rotary furnace. The study investigated at first the foaming behavior of different foam glass formulations at various sintering temperatures. Three compositions were formulated which utilized glass powder at 85 wt%, 90 wt%, and 95 wt%, respectively. Sintering was carried out at temperatures from 800℃ to 1200℃ to evaluate for the foaming and melting characteristics. Foam glass with 90% glass powder showed overall uniform pore size distribution and small pores at 800℃ to 900℃ while heating above 1000℃ resulted in sample distortion caused by glass melting and the collapse of foam glass structure. Foam glass composition with 90% glass powder was selected for the fabrication of foam glass granules at the sintering temperatures of 850℃ and 900℃ in rotary furnace. The best result was obtained at 850℃ where the granules did not melt and stick together whereas at 900℃ glass melting on the surface of the foam glass granules occurred significantly.

Downloads

References

J. König, R. R. Petersen, and Y. Z. Yue, “Fabrication of highly insulating foam glass made from CRT panel glass,” Ceramics International, vol. 41, pp. 9793-9800, 2015.

Q. Zhang, F. He, Y. Qiao, S. X. Mei, M. F. Jin, and J. Xie, “Preparation of high strength glass ceramic foams from waste cathode ray tube and germanium tailings,” Construction and Building Materials, vol. 111, pp. 105-110, 2016.

M. T. Souza, B. G. Oliveira Maia, L. B. Teixeira, K. G. Oliveira, A. Teixeira, and A. P. N. Oliveira, “Glass foams produced from glass bottles and eggshell wastes,” Process Safety and Environmental Protection, vol. 111, pp. 60-64, 2017.

Y. L. Wei, S. H. Cheng, K. T. Ou, P. J. Kuo, T. H. Chung, and X. Q. Xie, “Effect of calcium compounds on lightweight aggregates prepared by firing a mixture of coal fly ash and waste glass,” Ceramics International, vol. 43, no. 17, pp. 15573-15579, 2017.

Y. Attilaa, M. Güden, and A. Taşdemirci, “Foam glass processing using a polishing glass powder residue,” Ceramic International, vol. 39, pp. 5869-5877, 2013.

G. Bumanis, D. Bajare, and A.Korjakins, “Mechanical and thermal properties of lightweight concrete made from expanded glass”, Journal of Sustainable Architecture and Civil Engineering, vol. 2, no. 3, pp. 19-25, 2003.

G. Bumanis, D. Bajare, J. Locs, and A. Korjakins, “Alkali-silica reactivity of foam glass granules in structure of lightweight concrete,” Construction and building materials, vol. 47, pp. 274-281, 2013.

S. K. Adhikary, D. K. Ashish, and Ž. Rudžionis, “Expanded glass as light-weight aggregate in concrete – A review,” Journal of Cleaner Production, vol. 313, no. 1, p. 127848, 2021.

R. R. Petersen, J. König, and Y. Yue, “The viscosity window of the silicate glass foam production,” Journal of Non-Crystalline Solids, vol. 456, pp. 49-54, 2017.

M. Zhu, R. Ji, Z.M. Li, H. Wang, L. L. Liu, and Z. Zhang, “Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass,” Construction and Building Materials, vol. 112, pp. 398-405, 2016.

J. König, R. R. Petersen, and Y. Z. Yue, “Influence of the glass–calcium carbonate mixture's characteristics on the foaming process and the properties of the foam glass,” Journal of European Ceramic Society, vol. 34, pp. 1591-1598, 2014

H. Fernandes, D. Tulyaganov, and J. Ferreira, “Preparation and characterization of foams from sheet glass and fly ash using carbonates as foaming agents,” Ceramics International, vol. 35, no. 1, pp. 229-235, 2009.

J. König, R. R. Petersen, and Y. Yue, “Influence of the glass particle size on the foaming process and physical characteristics of foam glasses,” Journal of Non-Crystalline Solids, vol. 447, pp. 190-197, 2016.

Y. N Qu, J. Xu, Z. G. Su, N. Ma, X. Y. Zhang, X. Q. Xi, and J. L. Yang, “Lightweight and high-strength glass foams prepared by a novel green spheres hollowing technique,” Ceramics International, vol. 42, no. 2, pp. 2370-2377, 2016.

N. H. Chen, S. H. Zhang, X. Y. Pan, S. Zhou, and M. Zhao, “Foaming mechanism and optimal process conditions of foamed glass based on thermal analysis,” Journal of Porous Materials, vol. 27, pp. 621-626, 2020.

D. Hesky, C. G. Aneziris, U. Gross, and A. Horn, “Water and waterglass mixtures for foam glass production,” Ceramics International, vol. 41, no. 10, pp. 12604-12613, 2015.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.