The effect of mixing sequence on synthesis of PP-g-GMA compatibilizer for multilayer packaging (MLP) compounding

DOI:

https://doi.org/10.55713/jmmm.v34i2.1789Keywords:

multilayer food packaging, PP-g-GMA, GMA grafting degree, Inititator, CompatibilizerAbstract

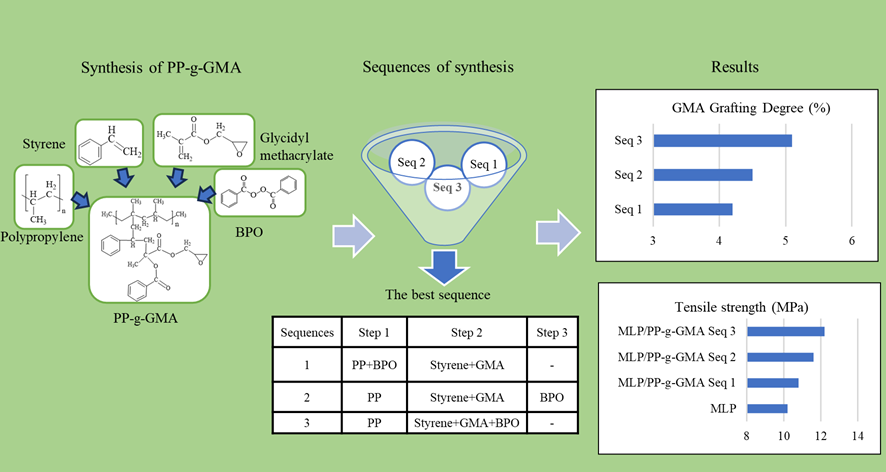

Melt recycling Multilayer Packaging (MLP) waste is difficult due to challenging separation procedures. However, blending techniques with compatibilizers can simplify MLP waste melt recycling. PP-g-GMA is a common compatibilizer in polyolefin and PET blends. PP-g-GMA compatibilizer was synthesized by utilizing an internal mixer at 175℃, 50 rpm, and 10 min using styrene as a comonomer. Titration was a method to examine effect of three different sequences of adding the BPO initiator on GMA grafting. Each sequence's PP-g-GMA samples were compounded with MLP waste using a twin-screw extruder and injection molded to make tensile test specimens. FTIR analysis shows that the GMA and Styrene monomers had grafted onto the PP polymer backbone, with the GMA grafting degree by varying mixing sequence. Sequence 3, which introduced initiator, GMA, and styrene simultaneously to PP melt, yielded PP-g-GMA with the most significant GMA grafting degree of 5.11%. Adding PP-g-GMA produced from sequence 3 into the MLP melt enhanced the highest increase in tensile strength and elongation at break of the MLP/PP-g-GMA compound.

Downloads

References

L. C. M. Lebreton, J. Van Der Zwet, J. W. Damsteeg, B. Slat, A. Andrady, and J. Reisser, “River plastic emissions to the world’s oceans,” Nature Communications, vol. 8, pp. 1-10, 2017. DOI: https://doi.org/10.1038/ncomms15611

D. Honingh, T. van Emmerik, W. Uijttewaal, H. Kardhana, O. Hoes, and N. van de Giesen, “Urban river water level increase through plastic waste accumulation at a rack structure,” Frontiers in Earth Science, vol. 8, no. February, pp. 1-8, 2020. DOI: https://doi.org/10.3389/feart.2020.00028

K. Kaiser, M. Schmid, and M. Schlummer, “Recycling of polymer-based multilayer packaging: A review,” Recycling, vol. 3, no. 1, 2018.1. DOI: https://doi.org/10.3390/recycling3010001

M. C. Mulakkal, A. C. Castillo, A. C. Taylor, B. R. K. Blackman, D. S. Balint, S. Pimenta, and M. N. Charalambides, “Advancing mechanical recycling of multilayer plastics through finite element modelling and environmental policy,” Resources,Conservation and Recycling, vol. 166, no. December 2020, p. 105371, 2021. DOI: https://doi.org/10.1016/j.resconrec.2020.105371

L. Delva, C. Deceur, N. Van Damme, and K. Ragaert, “Compatibilization of PET-PE blends for the recycling of multilayer packaging foils,” in AIP Conference Proceedings, American Institute of Physics Inc., Jan. 2019. DOI: https://doi.org/10.1063/1.5084815

M. Nechifor, F. Tanasă, C. A. Teacă, and M. Zănoagă, “Compatibilization strategies toward new polymer materials from re-/up-cycled plastics,” International Journal of Polymer Analysis and Characterization, vol. 23, no. 8, pp. 740-757, 2018. DOI: https://doi.org/10.1080/1023666X.2018.1509493

D. Feldman, “Polyblend compatibilization,” Journal of Macro-molecular Science - Pure and Applied Chemistry, vol. 42 A, no. 5, pp. 587-605, 2005. DOI: https://doi.org/10.1081/MA-200056331

Z. Baccouch, S. Mbarek, and M. Jaziri, “Experimental investigation of the effects of a compatibilizing agent on the properties of a recycled poly(ethylene terephthalate)/ polypropylene blend,” Polymer Bulletin, vol. 74, no. 3, pp. 839-856, 2017. DOI: https://doi.org/10.1007/s00289-016-1748-6

M. S. Lima, Á. A. Matias, J. R. C. Costa, A. C. Fonseca, J. F. J. Coelho, and A. C. Serra, “Glycidyl methacrylate-based copolymers as new compatibilizers for polypropylene/ polyethylene terephthalate blends,” Journal of Polymer Research, vol. 26, no. 6, 2019. DOI: https://doi.org/10.1007/s10965-019-1784-7

J. L. Li and X. M. Xie, “Reconsideration on the mechanism of free-radical melt grafting of glycidyl methacrylate on polyolefin,” Polymer (Guildf)., vol. 53, no. 11, pp. 2197-2204. DOI: https://doi.org/10.1016/j.polymer.2012.03.035

S. H. P. Bettini and A. C. R. Filho, “Styrene-assisted grafting of maleic anhydride onto polypropylene by reactive processing,” Journal of Applied Polymer Science, vol. 107, no. 3, pp. 1430-1438, 2008. DOI: https://doi.org/10.1002/app.27201

Q. Shi, L. Zhu, C. L. Cai, J. H. Yin, and G. Costa, “Kinetics study on melt grafting copolymerization of LLDPE with acid monomers using reactive extrusion method,” Journal of Applied Polymer Science, vol. 101, no. 6, pp. 4301-4312, 2006. DOI: https://doi.org/10.1002/app.23877

O. M. Jazani et al., “An investigation on the role of GMA grafting degree on the efficiency of PET/PP-g-GMA reactive blending: morphology and mechanical properties,” Polymer Bulletin, vol. 74, no. 11, pp. 4483-4497, 2017. DOI: https://doi.org/10.1007/s00289-017-1962-x

M. Daneshvar and M. Mahmood, “Synthesis and Application of MDPE-g-GMA as reactive compatibilizer in blends of MDPE/PET and MDPE/PA6,” Journal of Applied Polymer Science, vol. 124, no. 3, pp. 2048-2054, 2012 DOI: https://doi.org/10.1002/app.35235

M. H. Kunita, M. R. Gulherme, L. C. Filho, E. C. Muniz, E. Franceschi, C. Dariva, and A. F. Rubira, “Solid-state radical grafting reaction of glycidyl methacrylate and poly(4-methyl-1-pentene) in super-critical carbon dioxide: Surface morphology and adhesion,” Journal of Colloid and Interface Science, vol. 361, no. 1, pp. 331-337, 2011. DOI: https://doi.org/10.1016/j.jcis.2011.05.024

S. O. Celik, “The release potential of microplastics from face masks into the aquatic environment,” Sustainability, vol. 15, no. 19, 2023. DOI: https://doi.org/10.3390/su151914293

H. Cartier, and G.-H. HU, “Styrene-assisted melt free radical grafting of glycidyl methacrylate onto polypropylene,” Journal of Polymer Science Part A Polymer Chemistry, vol. 36, pp. 1053-1063, 1998.. DOI: https://doi.org/10.1002/(SICI)1099-0518(199805)36:7<1053::AID-POLA3>3.0.CO;2-3

S. Wang, N. Wang, L. Meng, J. Zhao, and Y. Feng, “Multi functionalization of polypropylene with controlled degradation and its structure characterization,” Macromolecular Research, vol. 19, no. 9, pp. 951-964, 2011. DOI: https://doi.org/10.1007/s13233-011-0907-8

X. M. Xie, N. H. Chen, B. H. Guo, and S. Li, “Study of multi-monomer melt-grafting onto polypropylene in an extruder,” Polymer International, vol. 49, no. 12, pp. 1677-1683, 2000. DOI: https://doi.org/10.1002/1097-0126(200012)49:12<1677::AID-PI590>3.0.CO;2-0

E.-L. Burton, M. Woodhead, P. Coates, and T. Gough, “Reactive grafting of glycidyl methacrylate onto polypropylene,” Journal of Applied Polymer Science, vol. 117, no. 5, pp. 2707-2714, 2010. DOI: https://doi.org/10.1002/app.31085

M. . Stevens and I. Sopyan, Kimia Polimer. Jakarta: Pradnya Paramita, 2001.

A. E. Hamielec, P. E. Gloor, and S. Zhu, “Kinetics of, free radical modification of polyolefins in extruders – chain scission, crosslinking and grafting,” The Canadian Journal of Chemical Engineering, vol. 69, no. 3, pp. 611-618, 1991. DOI: https://doi.org/10.1002/cjce.5450690302

N. C. Abdul Razak, I. M. Inuwa, A. Hassan, and S. A. Samsudin, “Effects of compatibilizers on mechanical properties of PET/ PP blend,” Composite Interfaces, vol. 20, no. 7, pp. 507-515, 2013. DOI: https://doi.org/10.1080/15685543.2013.811176

G. A. Uehara, M. P. França, and S. V Canevarolo Junior, “Recycling assessment of multilayer flexible packaging films using design of experiments,” Polimeros, vol. 25, no. 4, pp. 371-381, 2015. DOI: https://doi.org/10.1590/0104-1428.1965

L. Song, Q. Zhang, Y. Hao, Y. Li, W. Chi, Y. Shi, and L-Z, Liu, “Effect of different comonomers added to graft copolymers on the properties of PLA/PPC/PLA-g-GMA blends,” Polymers (Basel)., vol. 14, no. 19, 2022. DOI: https://doi.org/10.3390/polym14194088

A. S. Adekunle, A. A. Adeleke, C. V. Sam Obu, P. P. Ikubanni, S. E. Ibitoye, and T. M. Azeez, “Recycling of plastics with compatibilizer as raw materials for the production of automobile bumper,” Cogent Engineering, vol. 7, no. 1, 2020. DOI: https://doi.org/10.1080/23311916.2020.1801247

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.