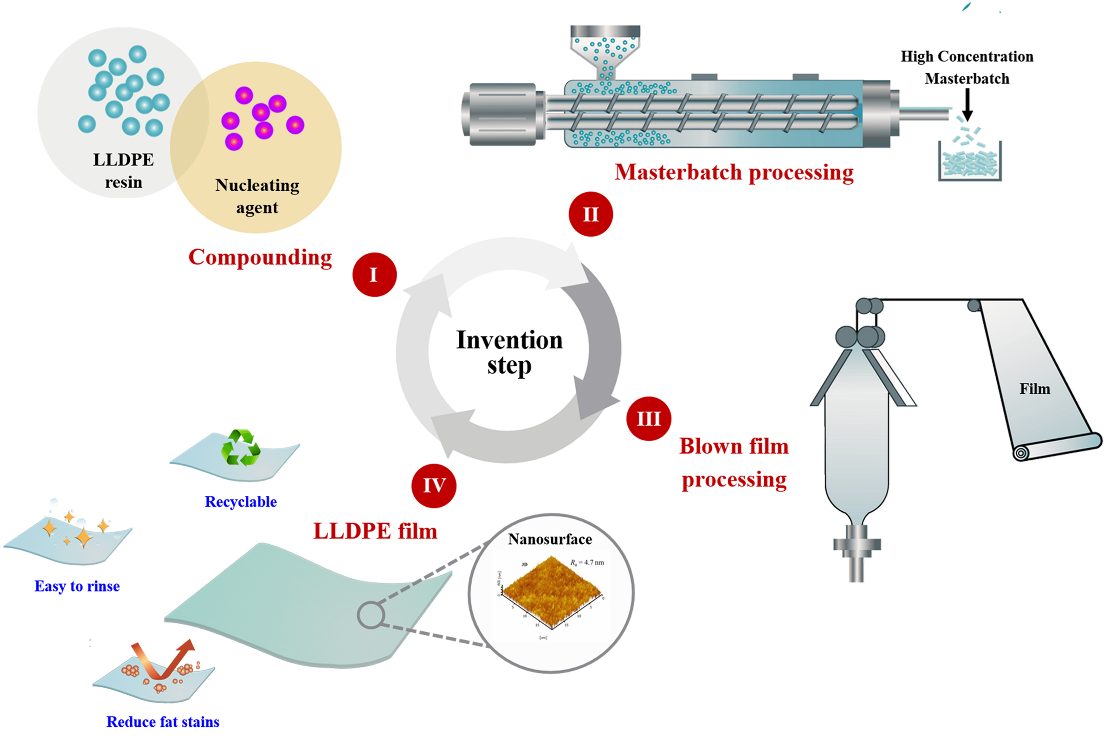

LLDPE film development surface with nucleating agents to reduce fat stains from food adherence on the film surface for easy rinsing before recycling

DOI:

https://doi.org/10.55713/jmmm.v34i1.1807Keywords:

LLDPE, Fat stains, Nucleating agent, Film surface, Blown filmAbstract

The purpose of this research was to enhance the surface of linear low-density polyethylene (LLDPE) film by using single and hybrid nucleating agents to reduce fat stains from food adherence on the film surface for easy rinsing before recycling, consequently reducing energy consumption before recycling. The process begins with the preparation of a high-concentration masterbatch of LLDPE with nucleating agents and polyethylene glycol (PEG), followed by blown film and test analysis. The results showed that both single and hybrid nucleating agents resulted in substantial modifications in the surface characteristics of the film. The altered surface texture of the film makes fat stains easy to remove. In addition, the use of hybrid nucleating agents resulted in considerable roughness on the film's surface. It can calculate the average roughness (Ra) from atomic force microscopy (AFM) images, which is very low at 4.7 nm, and the roughness is consistent. The contact angle was 99.17 degrees, and the percentage of crystallinity was clearly higher than that of a single nucleating agent. As a result, the fat stains on the film surface are easier to remove. The visual appearance, morphology, functional group, and mechanical properties of the films, on the other hand, were not significantly different. In summary, using a nucleating agent helped to rinse fat stains from the film easily.

Downloads

References

E. Tito, J. S. dos Passos, S. Bensaid, R. Pirone, and P. Biller, "Multilayer plastic film chemical recycling via sequential hydrothermal liquefaction," Resources, Conservation and Recycling, vol. 197, pp. 107067, 2023.

N. Pinpru, and S. Woramongkolchai, "Crosslinking effects on alginate/carboxymethyl cellulose packaging film properties," Chiang Mai Journal of Science, vol. 47, no. 4, pp. 712-722, 2020.

A. Khumkomgool, T. Saneluksana, and N. Harnkarnsujarit, "Active meat packaging from thermoplastic cassava starch containing sappan and cinnamon herbal extracts via LLDPE blown-film extrusion," Food Packaging and Shelf Life, vol. 26, p. 100557, 2020.

Y. Shen, F. Hu, X. X. Zhang, K. Thakur, K. R. R. Rengasamy, M. R. Khan, R. Busquets, and Z. J. Wei, "Fortification of poly-saccharide-based packaging films and coatings with essential oils: A review of their preparation and use in meat preservation," International Journal of Biological Macromolecules, vol. 242, pp. 124767, 2023.

T. Tábi, T. Ageyeva, and J. G. Kovács, "The influence of nucleating agents, plasticizers, and molding conditions on the properties of injection molded PLA products," Materials Today Communications, vol. 32, p. 103936, 2022.

Y. Phuphuak, Y. Miao, P. Zinck, and S. Chirachanchai, "Balancing crystalline and amorphous domains in PLA through star-structured polylactides with dual plasticizer/nucleating agent functionality," Polymer, vol. 54, no. 26, pp. 7058-7070, 2013.

X. Liu, X. Miao, X. Cai, J. Shao, F. Zou, W. Song, J. Qiao, and C. Wu, "The orientation of the dispersed phase and crystals in an injection-molded impact polypropylene copolymer," Polymer Testing, vol. 90, pp. 106658, 2020.

Y. Huang, G. Chen, Z. Yao, H. Li, and Y. Wu, "Non-isothermal crystallization behavior of polypropylene with nucleating agents and nano-calcium carbonate," European Polymer Journal, vol. 41, no. 11, pp. 2753-2760, 2005.

A. Anam, N. Gamit, V. Prajapati, and B. Z. Dholakiya, "An overview of kaolin and its potential application in thermosetting polymers," Materials Today Communications, vol. 36, p 106827, 2023.

S. C. S. Teixeira, M. M. Moreira, A. P. Lima, L. S. Santos, B. M. da Rocha, E. S. de Lima, R. A. A. F. da Costa, A. L. N. da Silva, M. C. G. Rocha, and F. M. B. Coutinho, "Study of blends of HDPE and different grades of CaCO3. Part I. Factorial experimental design," Polymer Testing, vol. 24, no. 8, pp. 983-987, 2005.

Z. A. Nur Hanani, F. Reich, T. Tolksdorf, H. Siemen, and N. Bandick, "Monitoring the effect of active packaging films with silver-kaolinite using different packaging systems on the quality of beef meat," Heliyon, vol. 8, no. 10, pp. e11019, 2022.

S. Kormin, F. Kormin, and M. D. H. Beg, "Effect of plasticizer on physical and mechanical properties of LDPE/sago starch blend," Journal of Physics: Conference Series, vol. 1150, p. 012032, 2019.

B. M. Tselana, S. Muniyasamy, V. O. Ojijo, and W. Mhike, "Melt processible biodegradable blends of polyethylene glycol plasticized cellulose diacetate with polylactic acid and poly-butylene adipate-co-terephthalate," Journal of Polymers and the Environment, pp. 1-18, 2023.

Y. D. Zhu, G. C. Allen, P. G. Jones, J. M. Adams, D. I. Gittins, P.J. Heard, and D.R. Skuse, "Dispersion characterisation of CaCO3 particles in PP/CaCO3 composites," Composites Part A: Applied Science and Manufacturing, vol. 60, pp. 38-43, 2014.

A. Mallik, A. K. Barikb, and B. Palb, "Comparative studies on physico-mechanical properties of compositematerials of low density polyethylene and raw/calcined kaolin," Journal of Asian Ceramic Societies, vol. 3, pp. 212-216, 2015.

Q. Chen, Z. Wang, S. Zhang, Y. Cao, and J. Chen, "Structure evolution and deformation behavior of polyethylene film during biaxial stretching," ACS Omega, vol. 5, no. 1, pp. 655-666, 2020.

M. Li, Y. Chen, L. Wu, Z. Zhang, and K. Mai, "A novel poly-propylene composite filled by kaolin particles with β-nucleation," Journal of Thermal Analysis and Calorimetry, vol. 135, no. 4, pp. 2137-2145, 2018.

M. Irani, H. Ismail, and Z. Ahmad, "Preparation and properties of linear low-density polyethylene-g-poly(acrylic acid)/ organo- montmorillonite superabsorbent hydrogel composites," Polymer Testing, vol. 32, no. 3, pp. 502-512, 2013.

Z. Zhang, C. Wang, J. Zhang, and K. Mai, "The β-nucleation of polypropylene random copolymer filled by nano-CaCO3 supported β-nucleating agent," Journal of Thermal Analysis and Calorimetry, vol. 109, no. 3, pp. 1587-1596, 2011.

Y. An, S. Wang, R. Li, D. Shi, Y. Gao, and L. Song, "Effect of different nucleating agent on crystallization kinetics and morphology of polypropylene," e-Polymers vol. 19, pp. 32-39, 2019.

S. M. Davachi, B. S. Heidari, R. Sahraeian, and A. Abbaspourrad, "The effect of nanoperlite and its silane treatment on the crystallinity, rheological, optical, and surface properties of polypropylene/nanoperlite nanocomposite films," Composites Part B: Engineering, vol. 175, p. 107088, 2019.

A. G. Simanke, A. P. d. Azeredo, C. d. Lemos, and R. S. Mauler, "Influence of nucleating agent on the crystallization kinetics and morphology of polypropylene," Polímeros, vol. 26, no. 2, pp. 152-160, 2016.

V. Krmelová, M. Gavendová, T. Zatroch, J. Krmela, A. Dubec, B. Bizubová, M. Kleščík, and A. Balogová, "Structure and properties of nucleated polypropylene fibres," IOP Conference Series: Materials Science and Engineering, vol. 776, p. 012096, 2020.

H. Haham, M. Y. Shen, S. L. Billington, and C. W. Frank, "Comparison of nanocrystalline cellulose dispersion versus surface nucleation in poly(3‐hydroxybutyrate‐co‐3‐hydroxy-valerate) crystallization," SPE Polymers, vol. 1, no. 1, pp. 15-25, 2020.

M. Ghozali, E. Triwulandari, A. Haryono, and E. Yuanita, "Effect of lignin on morphology, biodegradability, mechanical and thermal properties of low linear density polyethylene/lignin biocomposites," IOP Conference Series: Materials Science and Engineering, vol. 223, p. 012022, 2017.

Z.-Z. Liu, G.-Q. Zheng, H.-H. Shi, C.-T. Liu, L.-W. Mi, Q. Li, and X.-H. Liu, "simultaneous enhancement of toughness and strength of stretched ipp film via tiny amount of β-nucleating agent under “shear-free” Melt-extrusion," Chinese Journal of Polymer Science, vol. 39, no. 11, pp. 1481-1488, 2021.

F. Ö. Özmıhçı and D. Balköse, "Effects of particle size and electrical resistivity of filler on mechanical, electrical, and thermal properties of linear low-density polyethylene-zinc oxide composites," Journal of Applied Polymer Science, vol. 130, no. 4, pp. 2734-2743, 2013.

Y. Wang, Y. Shi, W. Shao, Y. Ren, W. Dong, F. Zhang, and L. Z. Liu, "Crystallization, structures, and properties of different polyolefins with similar grafting degree of maleic anhydride," Polymers (Basel), vol. 12, no. 3, 2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.