Sustainable innovation in ballistic vest design: Exploration of polyurethane-coated hemp fabrics and reinforced sandwich epoxy composites against 9 mm and .40 S&W bullets

DOI:

https://doi.org/10.55713/jmmm.v33i4.1830Keywords:

Bulletproof vests, Hemp fabrics, Sandwich reinforcement, Gelatin blocksAbstract

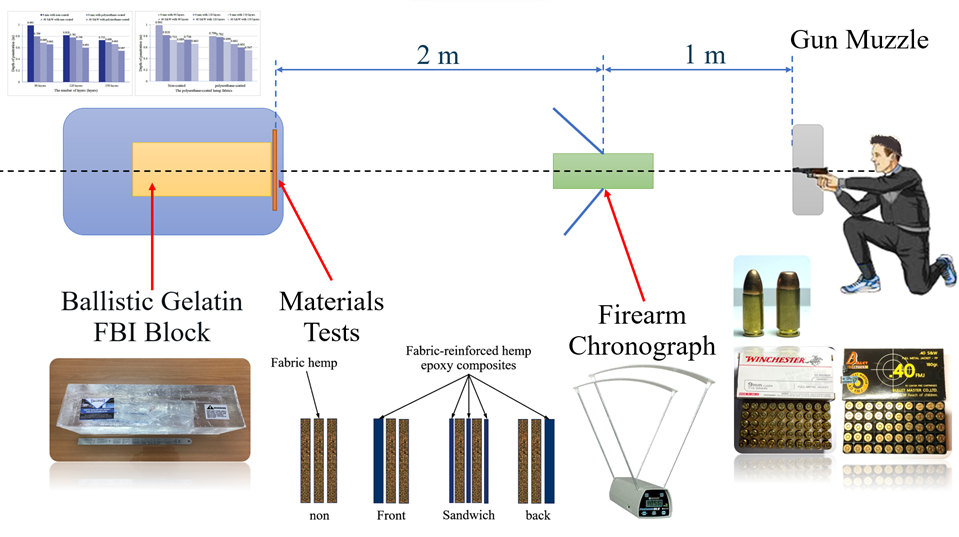

This research aimed to evaluate the bulletproof capabilities of hemp fabrics and optimize the design factors for effective ballistic vests. Three main aspects were investigated: enhancing toughness with polyurethane-coated hemp fabrics, determining optimal placement of fabric-reinforced hemp epoxy composites in various configurations, and identifying the optimal number of fabric layers for performance against 9 mm and .40 S&W bullets. Penetration depth was measured in ballistic gelatin to analyze the results. The study showed strong statistical correlations between factor variables and penetration depth shifts. The most effective strategies included polyurethane-coated hemp on all layers and increased layering. The ammunition of 9 mm bullets exhibited the least penetration depth when tested against the sandwich-reinforced configuration. In contrast, the larger .40 S&W bullets demonstrated that the frontal arrangement yielded the minimum penetration depth. Notably, 9 mm bullets penetrated 1.25 times deeper than .40 S&W bullets. These findings emphasize hemp fabric's potential for reliable ballistic vests. Utilizing polyurethane-coated hemp fabric in epoxy composites within a sandwich reinforcement of at least 212 layers is recommended to stop 9 mm bullets effectively. The research contributes valuable insights to sustainable ballistic vest development, utilizing natural materials with exceptional bullet protection capabilities.

Downloads

References

C. Neves, L. A. Rohen, D. P. Mantovani, G. Carvalho, F. Vieira, P.D. Lopes, N. T. Simonassi, F. S. da Luz, and S. N. Monteiro, “Comparative mechanical properties between biocomposites of Epoxy and polyester matrices reinforced by hemp fiber,” Journal of Materials Research and Technology, vol. 9, no. 2, pp. 1296-1304, 2020.

M. P. Ribeiro, L. M. Neuba, P. H. Silveira, F. S. Luz, A. B. Figueiredo, S. N. Monteiro and M. O. Moreira, “Mechanical, thermal and ballistic performance of epoxy composites reinforced with Cannabis sativa hemp fabric,” Journal of Materials Research and Technology, vol. 12, no. 3, pp. 221-233, 2021.

F. G. Filho, M. S. Oliveira, A. C. Pereira, L. F. C. Nascimento,

J. G. Matheus. and S. N. Monteiro, “Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition,” Journal of Materials Research and Technology, vol. 9, no. 2, pp. 1734-1741, 2020.

S. Doddamani, S. M. Kulkarni, S. Joladarashi, M. Kumar, and A. K. Gurjar, “Analysis of light weight natural fiber composites against ballistic impact: A review,” International Journal of Lightweight Materials and Manufacture, vol. 6, no. 3, pp. 450-468, 2023.

S. Siengchin, “A review on lightweight materials for defence applications: Present and future developments,” Defence Technology, vol. 24, pp. 1-17, 2023.

I. G. Crouch, “Body armour – New materials, new systems,” Defence Technology, vol. 15, no. 3, pp. 241-253, 2019.

S. Kar, S. Pattnaik, and M. K. Sutar, “Ballistic performance of green woven fabrics – A short review,” Materials Today: Proceedings, vol. 62, no. 10, pp. 5965-5970, 2022.

M. M. Ahmed, H. N. Dhakal, Z. Y. Zhang, A. Barouni, and R. Zahari, “Enhancement of impact toughness and damage behaviour of natural fibre reinforced composites and their hybrids through novel improvement techniques: A critical review,” Composite Structures, vol. 259, p. 113496, 2021.

T. Wantang, M. Pipathattakul, and F. Wiwatwongwana, “Investigating optimum factors for designing bulletproof vests using hemp fabric materials," in the 15th International Conference on Science, Technology and Innovation for Sustainable Well-Being, Luang Prabang, Lao PDR, 9 Aug. 2023, pp. 189-194.

F. G. Filho, M. S. Oliveira, A. C. Pereira, L. C. Nascimento, J. G. Matheus, and S. N. Monteiro, “Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition,” Journal of Materials Research and Technology, vol. 9, no. 2, pp. 1734-1741, 2020.

E. E. Haro, J. A. Szpunar and A. G. Odeshi, “Dynamic and ballistic impact behavior of biocomposite armors made of HDPE reinforced with chonta palm wood (Bactris gasipaes) microparticles,” Defence Technology, vol. 14, no. 3, pp. 238-249, 2018.

M. Shettar, P. Shettigar, M. Manjunath, and U. S. Rao, “Study on effect of water soaking conditions on properties and morphology of glass fiber–cement–polyester composites,” Journal of Materials Research and Technology, vol. 9, no. 4, pp. 8697-8704, 2020.

F. S. Assis, A. C. Pereira, F. G. Filho, É. P. Lima, S. N. Monteiro, and R. P. Web, “Performance of jute non-woven mat reinforced polyester matrix composite in multilayered armor,” Journal of Materials Research and Technology, vol. 7, no. 4, pp. 535-540, 2018.

A. O. Silva, K. C. Monsores, S. A. Oliveira, R. P. Weber, and S. N. Monteiro, “Ballistic behavior of a hybrid composite reinforced with curaua and aramid fabric subjected to ultraviolet radiation,” Journal of Materials Research and Technology, vol. 7, no. 4, pp. 584-591, 2018.

V. P. Matković, and Z. Skenderi, “Mechanical properties of polyurethane coated knitted fabrics,” Fibres and Textiles in Eastern Europe, vol. 100, no. 4, pp. 86-91, 2013.

M. H. Alizadeh, M. K. Dolatabadi, S. S. Najar, and R. E. Farsani, “Energy absorption of the Kevlar®/PP hybrid composite: fabric to composite optimization,” The Journal of The Textile Institute, vol. 113, no. 6, pp. 1018-1026, 2022.

H. Mohit, S. M. Rangappa, F. Gapsari, S. Siengchin, H. M. Marwani, A. Khan, and A. M. Asiri, “Effect of bio-fibers and inorganic fillers reinforcement on mechanical and thermal characteristics on carbon-kevlar-basalt-innegra fiber bio/ synthetic epoxy hybrid composites,” Journal of Materials Research and Technology, vol. 23, pp. 5440-5458, 2023.

S. Naik, R. D. Dandagwhal, and P. K. Loharkar, “A review on various aspects of Kevlar composites used in ballistic applications,” Materials Today: Proceedings, vol. 21, pp. 1366-1374, 2020.

S. S. Asemani, G. Liaghat, H. Ahmadi, Y. Anani, A. Khodadadi, and S. C. Charandabi, “The experimental and numerical analysis of the ballistic performance of elastomer matrix Kevlar composites,” Polymer Testing, vol. 102, p. 107311, 2021.

L. Gilson, A. Imad, L. Rabet, and F. Coghe, “On analysis of deformation and damage mechanisms of DYNEEMA composite under ballistic impact,” Composite Structures, vol. 253, p. 12791, 2020.

Z. Yuan, K. Wang, J. Qiu, Y. Xu, and X. Chen, “A numerical study on the mechanisms of Dyneema® quasi-isotropic woven panels under ballistic impact,” Composite Structures, vol. 236, p. 111855, 2020.

Y. Chu, R. Rahmana, S. Minb, and X. Chen, “Experimental and numerical study of inter-yarn friction affecting. mechanism on ballistic performance of Twaron® fabric,” Mechanics of Materials, vol. 148, p. 103421, 2020.

P. Zochowski, M. Bajkowski, R. Grygoruk, M. Magier, W. Burian, D. Pyka, M. Bocian, and K. Jamroziak, “Finite element modeling of ballistic inserts containing aramid fabrics under projectile impact conditions - Comparison of methods,” Composite structures, vol. 294, p. 115752, 2022.

B. Liu, Q. Liu, Y. Pan, J. Zhou, J. Zhang, S. Liu, Z. Fan, H. Deng, Y. Hu and X. Gong, “An impact-resistant and flame-retardant CNTs/STF/Kevlar composite with conductive property for safe wearable design,” Composites Part A: Applied Science and Manufacturing, vol. 168, pp. 107489, 2023.

J. Cline, and B. Love, “The effect of in-plane shear properties on the ballistic performance of polyethylene composites,” International Journal of Impact Engineering, vol. 143, p. 103592, 2020.

A. Giuntoli, N. K. Hansoge, and S. Keten, “Star topology increases ballistic resistance in thin polymer films,” Extreme Mechanics Letters, vol. 41 p. 101038, 2020.

V. D. Mishra, A. Mishra, A.Singh, L. Verm, and G. Rajesh, “Ballistic impact performance of UHMWP fabric impregnated with shear thickening fluid nanocomposite,” Composite Structures, vol. 281, p. 114991, 2022.

R. Zhang, L. S. Qiang, B. Han, Z. Y. Zhao, Q. C. Zhang, C. Y. Ni, and T. J. Lu, “Ballistic performance of UHMWPE laminated plates and UHMWPE encapsulated aluminum structures: Numerical simulation,” Composite Structures, vol. 252, pp. 112686, Nov. 2020.

Y. Deng, Y. Zhang, X. Xiao, A. Hu, H. Wu, and J. Xiong, “Experimental and numerical study on the ballistic impact behavior of 6061-T651 aluminum alloy thick plates against blunt-nosed projectile,” International Journal of Impact Engineering, vol. 144, p. 103659, 2020.

M. Kristoffersen, M. Costas, T. Koenis, V. Brøtan, C. O. Paulsen, and T. Børvik, “On the ballistic perforation resistance of additive manufactured AlSi10Mg aluminium plates,” International Journal of Impact Engineering, vol. 137, p. 103476, 2020.

M. K. Khan, M. A. Iqbal, V. Bratov, N. F. Morozov, and N. K. Gupta, “An investigation of the ballistic performance of independent ceramic target,” Thin-Walled Structures, vol. 154, p. 106784, 2020.

S. W. Maseko, A. I. Popoola, and O. I. Fayomi, “Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti-ballistic applications,” Defence Technology, vol. 14, no. 5, pp. 408-411, 2019.

M. M. Ahmed, H. N. Dhakal, Z. Y. Zhang, A. Barouni, and R. Zahari, “Enhancement of impact toughness and damage behaviour of natural fibre reinforced composites and their hybrids through novel improvement techniques: A critical review,” Composite Structures, vol. 259, p. 113496, 2021.

A. Bhat, J. Naveen, M. Jawaid, M. F. Norrrahim, A. Rashedi, and A. Khan, “Advancement in fiber reinforced polymer, metal alloys and multi-layered armour systems for ballistic applications - A review,” Journal of Materials Research and Technology, vol. 15, pp. 1300-1317, 2021.

M. Bajya, A. Majumdar, B. S. Butola, S. Arora, and D. Bhattacharjee, “Ballistic performance and failure modes of woven and unidirectional fabric based soft armour panels,” Composite Structures, vol. 255, p. 112941, 2021.

R. Stopforth, and S. Adali, “Experimental study of bullet-proofing capabilities of Kevlar, of different weights and number of layers, with 9 mm projectiles,” Defence Technology, vol. 15, no. 2, pp. 186-192, 2019.

K. N. Kumar, C. B. Kumar, K. H. Kumar, and B. Noolvi, “Investigation of composite sandwich plates for ballistic armor application,” Materials Today: Proceedings, vol. 27, no. 4, pp. 1738-1742, 2020.

National Institute of Justice. NIJ Standard-0101.07 Ballistic Resistance of Body Armor. Washington, DC. USA: 2018.

S. R. Ward, and R. L. Lieber, “Density and hydration of fresh and fixed human skeletal muscle,” Journal of Biomechanics, vol. 38, no. 11, pp. 2317-2320, 2005.

B. A. Lloyd. “Densities of Different Body Matter.” https://itis.swiss/

virtual/population/tissue/properties/database/density/(accessed Aug. 20, 2023).

M. A. Muflikhun, and B. Fiedler, “Failure prediction and surface characterization of GFRP laminates: A study of stepwise loading,” Polymers, vol. 14, no. 20, p. 4322, 2022.

T. Wantang, “Carbon fiber bulletproof armor plates,” Thailand Petty Patent 9250, Oct. 10, 2014.

S. Manigandan, T. R. Praveenkumar, A. M. Al-Mohaimeed, K. Brindhadevi, and A. Pugazhendhi, “Characterization of polyurethane coating on high performance concrete reinforced with chemically treated Ananas erectifolius fiber,” Progress in Organic Coatings, vol. 150, p. 105977, 2021.

T. Wantang, M. Pipathattakul, and F. Wiwatwongwana, “Experimental investigation of ballistic capabilities in Carbon-Kevlar composites: Effects of weight and layer variations against 9 mm projectiles,” Results in Materials, vol. 20, p. 100464, 2023.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.