Vibration absorption of as-built and post-heat-treated Ti-6Al-4V alloy fabricated by laser powder bed fusion additive manufacturing

DOI:

https://doi.org/10.55713/jmmm.v34i3.1963Keywords:

Additive manufacturing, Ti-6Al-4V, Vibration absorption, Anisotropy, Post-heat treatmentAbstract

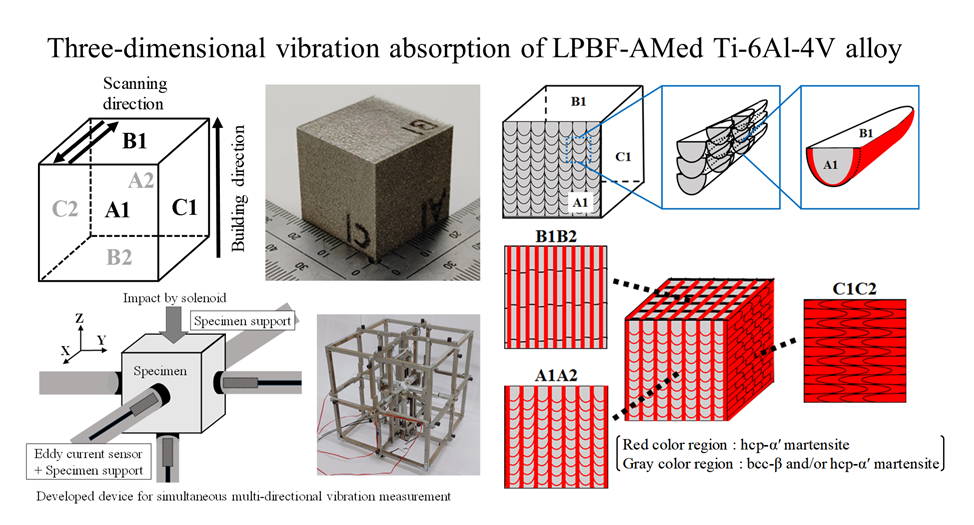

Vibration absorption of the Ti-6Al-4V alloy fabricated by laser powder bed fusion additive manufacturing (LPBF-AM) was evaluated following as-built and post-heat treatment (i.e., solution treatment followed by water quenching). The base plate was heated at 50°C or 200°C during building. Results showed that the vibration absorption of the as-built Ti-6Al-4V alloy was higher when the base plate was heated at 50°C than at 200°C. Further, the vibration absorption indicated strong anisotropy, with the highest vibration absorption in the direction perpendicular to the building direction and transverse to the laser scanning direction. However, after solution treatment followed by water quenching, the anisotropy in the vibration absorption of the LPBF-AMed Ti-6Al-4V alloy practically disappeared, and relatively high values were obtained parallel to each direction.

Downloads

References

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, “Additive manufacturing of metals,” Acta Materialia, vol. 117, pp. 371-392, 2016. DOI: https://doi.org/10.1016/j.actamat.2016.07.019

H. Ikeda, and T. Masuoka, “Application of the metal additive manufacturing technology for space vehicle,” Journal of the Japan Society of Precision Engineering, vol. 82, pp. 639-642, 2016. DOI: https://doi.org/10.2493/jjspe.82.639

J. Fujimoto, “Damping materials for spacecraft structures", The Journal of the INCE of Japan, vol. 15, pp. 45-49, 1991.

K. Yoshida, H. Seko, H. Sasano, Q. Shi, and S. Ando, "Acoustically induced random vibration analysis system for artificial satellite,” Mitsubishi Denki Giho, vol. 85,pp. 390-392, 2011.

S. Asano, and K. Ishii, “Internal Friction of Metals (2),” Denkiseiko, vol. 39, pp. 180-191, 1968. DOI: https://doi.org/10.4262/denkiseiko.39.180

K. Kawahara, and F. Yin, “New type of damping materials, M2052 alloys,” Journal of the Vacuum Society of Japan, vol. 42, pp.11-17, 1999. DOI: https://doi.org/10.3131/jvsj.42.11

Y. Mantani, T. Tsumura, and K. Nakata, “Effect of α’ martensite structure of Ti-15Nb alloy on material properties and its surface hardening treatment by plasma nitriding,” Journal of the Japan society for heat treatment, vol. 52, pp. 263-268, 2012.

Y. Mantani, and Y. Takemoto, “Change in crystal structure and material properties with deformation of quenched martensite in Ti-Nb alloys,” Journal of the Japan Institute of Metals and Materials, vol. 79, pp. 461-467, 2015. DOI: https://doi.org/10.2320/jinstmet.JAW201506

J. Yang, H. Yu, J. Yin, M. Gao, Z. Wang, and X. Zeng, “Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting,” Materials and Design, vol. 108, pp. 308-318, 2016. DOI: https://doi.org/10.1016/j.matdes.2016.06.117

J. J. S. Dilip, S. Zhang, C. Teng, K. Zeng, C. Robinson, D. Pal, and B. Stucker, “Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting,” Progress in Additive Manufacturing, vol. 2, pp. 157-167, 2017. DOI: https://doi.org/10.1007/s40964-017-0030-2

X. J. Jiang, S. J. Bao, L. W. Zhang, X. Y. Zhang, L. S. Jiao, H. B. Qi, and F. Wang, “Effect of Zr on microstructure and properties of TC4 alloy fabricated by laser additive manufacturing,” Journal of Materials Research and Technology, vol. 24, pp. 8782-8792, 2023. DOI: https://doi.org/10.1016/j.jmrt.2023.05.137

P. Köhnen, M. Létang, M. Voshage, J. H. Schleifenbaum, and C. Haase, “Understanding the process-microstructure correlations for tailoring the mechanical properties of L-PBF produced austenitic advanced high strength steel,” Additive Manufacturing, vol.30, no. 100914, 2019. DOI: https://doi.org/10.1016/j.addma.2019.100914

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, S. Johansson, and I. Smurov, “Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder,” Journal of Materials Processing Technology, vol. 213, pp. 606-613, 2013. DOI: https://doi.org/10.1016/j.jmatprotec.2012.11.014

X. Shi, C. Yan, W. Feng, Y. Zhang. and Z. Leng, “Effect of high layer thickness on surface quality and defect behavior of Ti-6Al-4V fabricated by selective laser melting,” Optics and Laser Technology, vol. 132, no. 106471, 2020. DOI: https://doi.org/10.1016/j.optlastec.2020.106471

H. Matsumoto, H. Yoneda, K. Sato, S. Kurosu, E. Maire, D. Fabregue, T. J. Konno, and A. Chiba, “Room-temperature ductility of Ti–6Al–4V alloy with α' martensitemicrostructure,” Materials Science and Engineering A, vol. 528, pp. 1512-1520, 2011. DOI: https://doi.org/10.1016/j.msea.2010.10.070

F. R. Kaschel, R. K. Vijayaraghavan, A. Shmeliov, E. K. McCarthy, M. Canavan, P. J. McNally, D. P. Dowling, V. Nicolosi, and M. Celikin, “Mechanism of stress relaxation and phase transformation in additively manufactured Ti-6Al-4V via in situ high temperature XRD and TEM analyses,” Acta Materialia, vol. 188, pp. 720-732, 2020. DOI: https://doi.org/10.1016/j.actamat.2020.02.056

T. Ishimoto, and T. Nakano, “Review-Microstructural control and functional enhancement of light metal materials via metal additive manufacturing,” Materials Transactions, vol. 64, pp. 10-16, 2023. DOI: https://doi.org/10.2320/matertrans.MT-MLA2022007

M. Simonelli, Y. Y. Tse, and C. Tuck, “On the texture formation of selective laser melted Ti-6Al-4V,” Metallurgical and Materials Transactions A, vol. 45, pp. 2863–2872, 2014. DOI: https://doi.org/10.1007/s11661-014-2218-0

H. Amano, T. Ishimoto, R. Suganuma, K. Aiba, S. Sun, R. Ozasa, and T. Nakano, “Effect of a helium gas atmosphere on the mechanical properties of Ti-6Al-4V alloy built with laser powder bed fusion: A comparative study with argon gas,” Additive Manufacturing, vol. 48, no. 102444, 2021. DOI: https://doi.org/10.1016/j.addma.2021.102444

S. Cao, Y. Zou, C.V.S. Lim, and X. Wu, “Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: process, post-process treatment, microstructure, and property,” Light: Advanced Manufacturing, vol. 2, pp. 313-332, 2021. DOI: https://doi.org/10.37188/lam.2021.020

Y. Xu, D. Zhang, Y. Guo, S. Hu, X. Wu, and Y. Jiang, “Micro-structural tailoring of As-Selective Laser Melted Ti6Al4V alloy for high mechanical properties,” Journal of Alloys and Compounds, vol. 816, no. 152536, 2020. DOI: https://doi.org/10.1016/j.jallcom.2019.152536

S. Li, B. Zhang, and Q. Bai, “Effect of temperature buildup on milling forces in additive/subtractive hybrid manufacturing of Ti-6Al-4V,” The International Journal of Advanced Manufacturing Technology, vol. 107, pp. 4191-4200, 2020. DOI: https://doi.org/10.1007/s00170-020-05309-7

Y. Mae, "”Damping mechanism and its characteristics of damping alloys,” Journal of the Japan Society of Precision Engineering, vol. 55, pp. 2123-2126, 1989. DOI: https://doi.org/10.2493/jjspe.55.2123

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.