Phase separation promotes FCC-phase mechanical twinning in AlCoCrFeMo0.05Ni2 high entropy alloy

DOI:

https://doi.org/10.55713/jmmm.v34i3.2107Keywords:

high entropy alloy, annealing, twin, deformation and fracture, high-temperatureAbstract

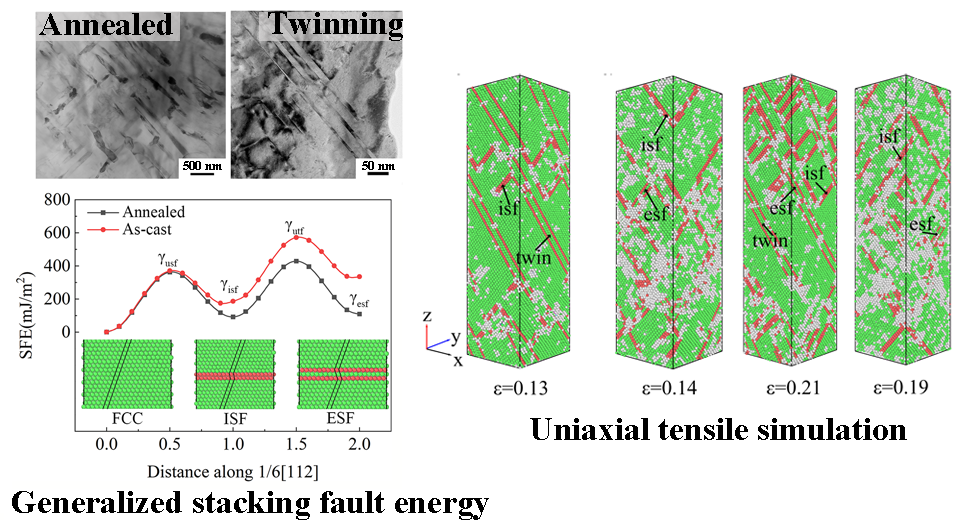

The AlCoCrFeMo0.05Ni2 high entropy alloy (HEA) can remarkably enhance its ductility through high-temperature annealing. Nevertheless, the underlying mechanism remains under explored. Herein, we utilized molecular dynamics simulations (MD) to calculate the generalized stacking fault energy (GSFE) curves and uniaxial tensile behavior. Notably, the twin inclination of the FCC phase increases significantly after annealing. During plastic deformation, the FCC phase in the annealed alloy exhibits a substantially higher formation of twinning and stacking faults compared to the as-cast alloy. This increased twin inclination after annealing is the fundamental mechanism contributing to the enhancement of high-temperature ductility.

Downloads

References

R. Darolia, "Development of strong, oxidation and corrosion resistant nickel-based superalloys: critical review of challenges, progress and prospects," International Materials Reviews, vol. 64, pp. 355-380, 2018. DOI: https://doi.org/10.1080/09506608.2018.1516713

B. Cantor, "Multicomponent and high entropy alloys," Entropy, vol. 16, pp. 4749-4768, 2014. DOI: https://doi.org/10.3390/e16094749

Y. Hu, and Y. Liu, "Constitutive behavior of semi-solid Al80Mg5Li5Zn5Cu5 light-weight high entropy alloy," Journal of Materials Research and Technology, vol. 29, pp. 5713-5720, 2024. DOI: https://doi.org/10.1016/j.jmrt.2024.03.004

O. N. Senkov, G. B. Wilks, D. B. Miracle, C. P. Chuang, and P. K. Liaw, "Refractory high-entropy alloys," Intermetallics, vol. 18, pp. 1758-1765, 2010. DOI: https://doi.org/10.1016/j.intermet.2010.05.014

X. Feng, Y. Yue, J. Qiu, J. Qiu, H. Jain, and S. Zhou, "Entropy engineering in inorganic non-metallic glass," Fundamental Research, vol. 2, pp. 783-793, 2022. DOI: https://doi.org/10.1016/j.fmre.2022.01.030

M. Ma, X. Yang, H. Meng, Z. Zhao, J. He, and Y. Chu, "Nanocrystalline high-entropy hexaboride ceramics enable remarkable performance as thermionic emission cathodes," Fundamental Research, vol. 3, pp. 979-987, 2023. DOI: https://doi.org/10.1016/j.fmre.2022.04.010

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, W. Zhijun, J. C. Jie, Z. Cao, H. H. Ruan, and Y. Lu., "A promising new class of high-temperature alloys: eutectic high-entropy alloys," Scientific reports, vol. 4, p. 6200, 2014. DOI: https://doi.org/10.1038/srep06200

T. Xiong, S. Zheng, J. Pang, and X. Ma, "High-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy achieved via precipitation strengthening in a heterogeneous structure," Scripta Materialia, vol. 186, pp. 336-340, 2020. DOI: https://doi.org/10.1016/j.scriptamat.2020.04.035

X. Jiang, Y. Li, P. Shi, Y. Yang, M. Wang, J. Huang, Y. Qin, Y. Lin, B. Tan, Y. Ruan, X. Wang, B. Zhou, B. Ding, Q. Li, Z. Shen, T. Zheng, C. Liu, P. K. Liaw, and Y. Zhong, "Synergistic control of microstructures and properties in eutectic high-entropy alloys via directional solidification and strong magnetic field," Journal of Materials Research and Technology, vol. 28, pp. 4440-4462, 2024. DOI: https://doi.org/10.1016/j.jmrt.2024.01.058

Q. Ye, G. Yang, and B. Yang, "Effect of aging on microstructure and property of AlCoCrFeMo0.05Ni2 high entropy alloy," Materials Science and Engineering: A, vol. 760, pp. 1-6, 2019. DOI: https://doi.org/10.1016/j.msea.2019.05.058

Q. Ye, G. Yang, and B. Yang, "Segregation engineering in a promising heat-resistant AlCoCrFeMo0.05Ni2 high entropy alloy," Journal of Alloys and Compounds, vol. 869, p. 159336, 2021. DOI: https://doi.org/10.1016/j.jallcom.2021.159336

Q. Ye, B. Yang, G. Yang, J. Zhao, and Z. Gong, "Stability prediction of AlCoCrFeMo0.05Ni2 high entropy alloy by Kinetic Monte Carlo method," Materials Letters, vol. 306, p. 130907, 2022. DOI: https://doi.org/10.1016/j.matlet.2021.130907

Q. Ye, Z. Zhang, Q. Wang, X. Xu, K. Wang, J. Zhao, B. Xu, J. Zhang, D. Liu, Y. Deng, X. Qian, Q. Wu, Y. Wang, Q. Cao, "Promoting nanoscale deformation twinning through FCC phase decomposition in AlCoCrFeMo0.05Ni2 high entropy alloy," Journal of Alloys and Compounds, vol. 985, p. 174086, 2024. DOI: https://doi.org/10.1016/j.jallcom.2024.174086

H. Luan, L. Huang, J. Kang, B. Luo, X. Yang, L. Jinfeng, Z. Han, J. Si, Y. Shao, J. Lu, and K. Yao, "Spinodal decomposition and the pseudo-binary decomposition in high-entropy alloys," Acta Materialia, vol. 248, p. 118775, 2023. DOI: https://doi.org/10.1016/j.actamat.2023.118775

F. He, Z. Wang, Q. Wu, J. Li, J. Wang, and C. T. Liu, "Phase separation of metastable CoCrFeNi high entropy alloy at intermediate temperatures," Scripta Materialia, vol. 126, pp. 15-19, 2017. DOI: https://doi.org/10.1016/j.scriptamat.2016.08.008

A. Munitz, L. Meshi, and M. J. Kaufman, "Heat treatments' effects on the microstructure and mechanical properties of an equiatomic Al-Cr-Fe-Mn-Ni high entropy alloy," Materials Science and Engineering: A, vol. 689, pp. 384-394, 2017. DOI: https://doi.org/10.1016/j.msea.2017.02.072

S. Singh, N. Wanderka, B. S. Murty, U. Glatzel, and J. Banhart, "Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy," Acta Materialia, vol. 59, pp. 182-190, 2011. DOI: https://doi.org/10.1016/j.actamat.2010.09.023

S. R. Oke, O. E. Falodun, A. Bayode, U. Anamu, and P. Olubambi, "Phase prediction, densification, and microstructure of AlCrFeNi (TiO2)x high entropy alloy composite fabricated by spark plasma sintering," Journal of Alloys and Compounds, vol. 968, p. 172030, 2023. DOI: https://doi.org/10.1016/j.jallcom.2023.172030

A. Bansal, P. Kumar, S. Yadav, V. Hariharan, M. Rahul, and G. Phanikumar, "Accelerated design of high entropy alloys by integrating high throughput calculation and machine learning," Journal of Alloys and Compounds, vol. 960, p. 170543, 2023. DOI: https://doi.org/10.1016/j.jallcom.2023.170543

S. Güler, E. D. Alkan, and M. Alkan, "Vacuum arc melted and heat treated AlCoCrFeNiTiX based high-entropy alloys: Thermo-dynamic and microstructural investigations," Journal of Alloys and Compounds, vol. 903, p. 163901, 2022. DOI: https://doi.org/10.1016/j.jallcom.2022.163901

P. Steve, "Fast parallel algorithms for short-range molecular dynamics," Journal of computational physics, vol. 117, pp. 1-19, 1995. DOI: https://doi.org/10.1006/jcph.1995.1039

F. Diana, and A. Caro, "Model interatomic potentials for Fe–Ni–Cr–Co–Al high-entropy alloys," Journal of Materials Research, vol. 35, pp. 3031-3040, 2020. DOI: https://doi.org/10.1557/jmr.2020.294

G. Ackland, and R. Thetford, "An improved N-body semi-empirical model for body-centred cubic transition metals," Philosophical Magazine A, vol. 56, pp. 15-30, 1987. DOI: https://doi.org/10.1080/01418618708204464

S. Alexander, "Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool," Modelling and simulation in materials science and engineering, vol. 18, p. 015012, 2009. DOI: https://doi.org/10.1088/0965-0393/18/1/015012

H. Swygenhoven, P. Derlet, and A. Frøseth, "Stacking fault energies and slip in nanocrystalline metals," Nature materials, vol. 3, pp. 399-403, 2004. DOI: https://doi.org/10.1038/nmat1136

D. Siegel, "Generalized stacking fault energies, ductilities, and twinnabilities of Ni and selected Ni alloys," Applied Physics Letters, vol. 87, p. 121910, 2005. DOI: https://doi.org/10.1063/1.2051793

E. Tadmor, and N. Bernstein, "A first-principles measure for the twinnability of FCC metals," Journal of the Mechanics and Physics of Solids, vol. 52, pp. 2507-2519, 2004. DOI: https://doi.org/10.1016/j.jmps.2004.05.002

N. Bernstein, and E. Tadmor, "Tight-binding calculations of stacking energies and twinnability in FCC metals," Physical Review B, vol. 69, p. 094116, 2004. DOI: https://doi.org/10.1103/PhysRevB.69.094116

T. Cai, Z. Zhang, P. Zhang, J. Yang, and Z. Zhang, "Competition between slip and twinning in face-centered cubic metals," Journal of Applied Physics, vol. 116, p. 163512, 2014. DOI: https://doi.org/10.1063/1.4898319

J. Kim, M. Kwon, and B. C. De Cooman, "On the deformation twinning mechanisms in twinning-induced plasticity steel," Acta Materialia, vol. 141, pp. 444-455, 2017. DOI: https://doi.org/10.1016/j.actamat.2017.09.043

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.