Nutrient retention and availability of biochars prepared by co-pyrolysis of vinasse with sugarcane filter cake

DOI:

https://doi.org/10.55713/jmmm.v34i4.2147Keywords:

Thermal treatment, Agricultural waste, sugarcane, Soil fertilizer, BiocharAbstract

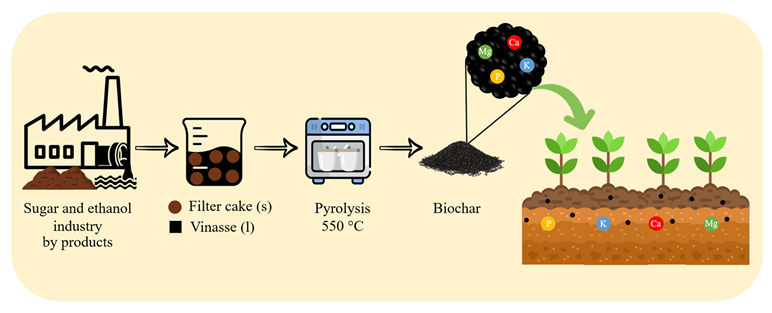

The disposal of vinasse, a nutrient-rich by-product of ethanol production, is challenging because of the low pH and emissions of harmful gases and smells. Here, biochars were produced by pyrolysis of mixtures of filter cake and vinasse (0.25 w/v to 1 w/v) at 550℃. The effects of filter cake to vinasse ratios on the biochar yield, pH, ash content, total nutrient (P, K, Ca, and Mg) content, and nutrient availability were investigated. Increasing the filter cake to vinasse ratio increased the biochar yield and ash content and lowered the biochar pH from 10.3 for 0.25-BC to 8.2 for filter cake biochar (FC-BC). Lower filter cake to vinasse ratios increased the total K content from 7.9 g∙kg‒1 for FC-BC to 75.9 for 0.25-BC. Nutrient recovery in the biochars was high (79.5% to 130.2%). Whereas P, Ca, and Mg extractability in water was <5%, the K extractability was 80% for 0.25-BC and decreased to 7.6% for FC-BC. Extractability of K, P, Ca, and Mg in 2% formic acid from vinasse-containing biochars was high (>50%). These results highlight the potential suitability for use in agricultural applications. Conversion of vinasse into value-added biochar could reduce waste treatment cost and improve soil health.

Downloads

References

USDA, “Sugar : World Markets and Trade 2023 / 24,” Foreign Agric. Serv. https//apps.fas.usda.gov/psdonline/circulars/sugar.pdf, no. November, pp. 1-9, 2023, [Online]. Available: https://fas.usda.gov/

data/sugar-world-markets-and-trade

R. D. M. Prado, G. Caione, and C. N. S. Campos, “Filter cake and vinasse as fertilizers contributing to conservation agriculture,” Applied and Environmental Soil Science, vol. 2013, no. 1, p. 581984, 2013. DOI: https://doi.org/10.1155/2013/581984

F. Santos, P. Eichler, G. Machado, J. De Mattia, and G. De Souza, By-products of the sugarcane industry. Elsevier Inc., 2019. DOI: https://doi.org/10.1016/B978-0-12-814236-3.00002-0

L. L. Campiteli, R. M. Santos, G. Lazarovits, and E. C. Rigobelo, “The impact of applications of sugar cane filter cake and vinasse on soil fertility factors in fields having four different crop rotations practices in Brazil,” Cientifica, vol. 46, no. 1, pp. 42-48, 2018, DOI: https://doi.org/10.15361/1984-5529.2018v46n1p42-48

C. A. Melo, F. H. S. Junior, M. C. Bisinoti, A. B. Moreira, and O. P. Ferreira, “Transforming sugarcane bagasse and vinasse wastes into hydrochar in the presence of phosphoric acid: An evaluation of nutrient contents and structural properties,” Waste and Biomass Valorization, vol. 8, no. 4, pp. 1139-1151, 2017. DOI: https://doi.org/10.1007/s12649-016-9664-4

E. Arslanoğlu, M. Ş. A. Eren, H. Arslanoğlu, and H. Çiftçi, “Fabrication, characterization, and adsorption applications of low-cost hybride activated carbons from peanut shell-vinasse mixtures by one-step pyrolysis,” Biomass Convers. Biorefinery, vol. 13, no. 3, pp. 2321-2335, 2023. DOI: https://doi.org/10.1007/s13399-021-01400-5

T. F. Abbruzzini, M. D. Oliveira Zenero, P. A. M. de Andrade, F. Dini Andreote, J. Campo, and C. E. Pellegrino Cerri, “Effects of biochar on the emissions of greenhouse gases from sugarcane residues applied to soils,” The Journal of Agricultural Science, vol. 08, no. 09, pp. 869-886, 2017. DOI: https://doi.org/10.4236/as.2017.89064

M. J. Dirbeba, A. Brink, N. DeMartini, D. Lindberg, and M. Hupa, “Sugarcane vinasse CO2 gasification and release of ash-forming matters in CO2 and N2 atmospheres,” Bioresource Technology, vol. 218, pp. 606-614, 2016. DOI: https://doi.org/10.1016/j.biortech.2016.07.004

D. R. Da Silva, M. S. Crespi, P. C. G. M. Crnkovic, and C. A. Ribeiro, “Pyrolysis, combustion and oxy-combustion studies of sugarcane industry wastes and its blends,” Journal of Thermal Analysis and Calorimetry, vol. 121, no. 1, pp. 309-318, 2015. DOI: https://doi.org/10.1007/s10973-015-4532-1

R. Chatterjee, B. Sajjadi, W. Y. Chen, D. L. Mattern, N. Hammer, V. Raman, and A. Dorris, “Effect of pyrolysis temperature on physicochemical properties and acoustic-based amination of biochar for efficient CO2 adsorption,” Frontiers in Energy Research, vol. 8, p. 85, 2020. DOI: https://doi.org/10.3389/fenrg.2020.00085

M. J. Dirbeba, A. Aho, N. Demartini, A. Brink, I. Mattsson, L. Hupa, and M. Hupa, “Fast pyrolysis of dried sugar cane vinasse at 400 and 500°C: Product distribution and yield,” Energy and Fuels, vol. 33, no. 2, pp. 1236-1247, 2019. DOI: https://doi.org/10.1021/acs.energyfuels.8b03757

N. Kamali, A. RashidiMehrabadi, M. Mirabi, and M. A. Zahed, “Synthesis of vinasse-dolomite nanocomposite biochar via a novel developed functionalization method to recover phosphate as a potential fertilizer substitute” Frontiers of Environmental Science & Engineering, vol. 14, no. 4, p. 70, 2020. DOI: https://doi.org/10.1007/s11783-020-1249-6

A. E. E. A. Z. Amin, “Bagasse pith-vinasse biochar effects on carbon emission and nutrient release in calcareous sandy soil,” Journal of Soil Science and Plant Nutrition, vol. 20, no. 1, pp. 220-231, 2020. DOI: https://doi.org/10.1007/s42729-019-00125-9

F. N. Türk and H. Arslanoğlu, “Recovery of potassium from pyrolysis product of sugar fabrication waste carbonation cake and vinasse mixture and production of adsorbent for wastewater treatment,” Journal Sugar Tech, vol. 26, no. 2, pp. 478-488, 2024. DOI: https://doi.org/10.1007/s12355-024-01364-6

S. Suwanree, J. T. N. Knijnenburg, P. Kasemsiri, W. Kraithong, P. Chindaprasirt, and K. Jetsrisuparb, “Engineered biochar from sugarcane leaves with slow phosphorus release kinetics,” Biomass and Bioenergy, vol. 156, no. March 2021, p. 106304, 2022. DOI: https://doi.org/10.1016/j.biombioe.2021.106304

S. Suwanree, K. Jetsrisuparb, P. Kasemsiri, P. Tharamas, H. Uyama, S. Kuboon, and J. T. N. Knijnenburg, “Influence of magnesium content and phosphoric acid treatment on cadmium adsorption onto sugarcane leaf biochar,” Research on Chemical Intermediates, vol. 50, no. 8, pp. 3981-4001, 2024. DOI: https://doi.org/10.1007/s11164-024-05329-y

T. Wang, M. Camps-Arbestain, M. Hedley, and P. Bishop, “Predicting phosphorus bioavailability from high-ash biochars,” Plant and Soil, vol. 357, no. 1, pp. 173-187, 2012. DOI: https://doi.org/10.1007/s11104-012-1131-9

K. Sun, M. Qiu, L. Han, J. Jin, Z. Wang, Z. Pan, and B. Xing, “Speciation of phosphorus in plant- and manure-derived biochars and its dissolution under various aqueous conditions,” Science of the Total Environment, vol. 634, pp. 1300-1307, 2018. DOI: https://doi.org/10.1016/j.scitotenv.2018.04.099

S. Meunchang, S. Panichsakpatana, and R. W. Weaver, “Co-composting of filter cake and bagasse; by-products from a sugar mill,” Bioresource Technology, vol. 96, no. 4, pp. 437-442, 2005. DOI: https://doi.org/10.1016/j.biortech.2004.05.024

L. A. G. de Godoi, P. R. Camiloti, A. N. Bernardes, B. L. S. Sanchez, A. P. R. Torres, A. da C. Gomes, and L. S. Botta, “Seasonal variation of the organic and inorganic composition of sugarcane vinasse : Main implications for its environmental uses generating as byproduct a viscous phase called molasses,” Environmental Science and Pollution Researchvol, 26, pp. 29267-29282, 2019. DOI: https://doi.org/10.1007/s11356-019-06019-8

J. S. Devia-Orjuela, C. E. Alvarez-Pugliese, D. Donneys-Victoria, N. M. Cabrales, L. E. B. Ho, B. Brém, A. Sauciuc, E. Gál, D. Espin, M. Schichtel, D. Lang, S. Giardinelli, and M. Briceno, “Evaluation of press mud, vinasse powder and extraction sludge with ethanol in a pyrolysis process,” Energies, vol. 12, no. 21, pp. 1-21, 2019. DOI: https://doi.org/10.3390/en12214145

H. M. Tun, H. Myat, T. Swe, N. Wah, and P. S. Win, “Software development of distributed control system-based sugar mill using visual studio. net,” ITS, vol. 5, no. 2, pp. 2617-4537, 2021.

D. R. da Silva, M. S. Crespi, C. A. Ribeiro, and J. M. V. Capela, “Thermal decomposition kinetics of sugarcane mills wastes,” Journal of Thermal Analysis and Calorimetry, vol. 131, no. 1, pp. 811-822, 2018. DOI: https://doi.org/10.1007/s10973-017-6270-z

K. Jetsrisuparb, T. Jeejaila, C. Saengthip, P. Kasemsiri, Y. Ngernyen, P. Chindaprasirt, and J. T. N. Knijnenburg, “Tailoring the phosphorus release from biochar-based fertilizers: role of magnesium or calcium addition during co-pyrolysis,” RSC Advances, vol. 12, no. 47, pp. 30539-30548, 2022. DOI: https://doi.org/10.1039/D2RA05848K

J. T. N. Knijnenburg, P. Kasemsiri, W. Kaewpradit, T. Tarinta, W. Jantapa, T. Jeejaila, C. Saengthip, and K. Jetsrisuparb, “Co-pyrolysis of biomass with magnesium and phosphorus: Effect of magnesium content on phosphate release from biochar-based fertilizers,” Biomass Conversion and Biorefinery, vol. 14, no. 14, pp. 15351-15361, 2024. DOI: https://doi.org/10.1007/s13399-023-03994-4

M. J. Buer Boyetey, S. Torgbo, P. Sukyai, N. Watthanasakphuban, and N. Kamonsutthipaijit, “Filter cake-derived calcium carbonate polymorphs from sugar refinery for hydroxyapatite production as a sustainable material for biomedical application,” Ceramics International, vol. 49, no. 14, pp. 23417-23425, 2023. DOI: https://doi.org/10.1016/j.ceramint.2023.04.174

M. J. Dirbeba, A. Brink, M. Zevenhoven, N. Demartini, D. Lindberg, L. Hupa, and M. Hupa, “Characterization of vinasse for thermochemical conversion - fuel fractionation, release of inorganics, and ash-melting behavior,” Energy and Fuels, vol. 33, no. 7, pp. 5840-5848, 2019. DOI: https://doi.org/10.1021/acs.energyfuels.8b04177

T. K. Choudhary, K. S. Khan, Q. Hussain, M. Ahmad, and M. Ashfaq, “Feedstock-induced changes in composition and stability of biochar derived from different agricultural wastes,” The Arabian Journal of Geosciences, vol. 12, no. 20, 2019. DOI: https://doi.org/10.1007/s12517-019-4735-z

G. Bekiaris, C. Peltre, L. S. Jensen, and S. Bruun, “Using FTIR-photoacoustic spectroscopy for phosphorus speciation analysis of biochars,” Spectrochimica Acta, Part A: Molecular and Biomolecular Spectroscopy, vol. 168, pp. 29-36, 2016. DOI: https://doi.org/10.1016/j.saa.2016.05.049

K. Wang, N. Peng, G. Lu, and Z. Dang, “Effects of pyrolysis temperature and holding time on physicochemical properties of swine-manure-derived biochar,” Waste and Biomass Valorization, vol. 11, no. 2, pp. 613-624, 2020. DOI: https://doi.org/10.1007/s12649-018-0435-2

W. Buss, A. Bogush, K. Ignatyev, and O. Mašek, “Unlocking the fertilizer potential of waste-derived biochar,” ACS Sustainable Chemistry & Engineering, vol. 8, no. 32, pp. 12295-12303, 2020. DOI: https://doi.org/10.1021/acssuschemeng.0c04336

Downloads

Published

How to Cite

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.