Mineralogical studies and optimization of tabling parameters of low grade chromite ore by box behnken design of experiments

DOI:

https://doi.org/10.55713/jmmm.v32i4.1563Keywords:

Low-grade chromite ore, Wilfley table, Box-behnken statistical design, Tilt angle, Pre-heat treatmentAbstract

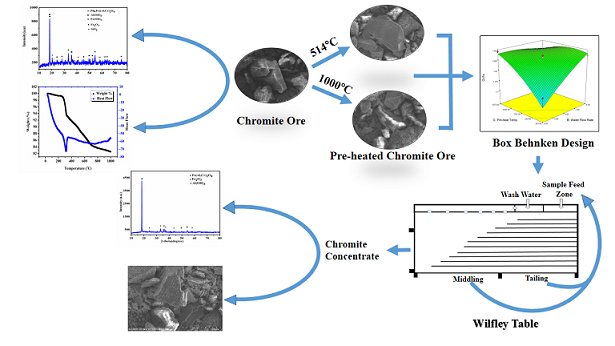

Chromite ore is geologically associated with gangue materials which have lower density compared to pure chromite (FeO.Cr2O3). Gravity separation techniques are very suitable for beneficiation of low grade chromite ore. In the present study mineralogical analysis of the sample has been carried out by using Wavelength dispersive x-ray fluorescence (WDXRF), X-ray powder diffraction (XRD), Scanning electron microscopy (SEM) and Energy dispersive X-ray (EDX). The beneficiation of low grade (Cr2O3% 26.88) chromite ore has been investigated using wilfley table. Optimization has been carried out using box-behnken statistical design (BBD). The experimental parameters selected are: tilt angle, water flow rate and pre-heat treatment of the chromite ore. It is observed that percentage recovery of Cr2O3 depends upon tilt angle, water flow rate and pre-heat treatment of chromite ore. Pre-heat treatment of chromite ore plays a vital role in gravity separation. The optimized tabling conditions suggested by BBD are 8° tilt angle, 4 L∙min-1 water flow rate and temperature for pre-heat treatment of raw chromite ore at 443.72℃. After tabling under optimized conditions, chromite concentrate contained 1.91 Cr/Fe ratio, 46.02% of Cr2O3 with 65.95% recovery.

Downloads

References

Indian Bureau of Mines, “Indian Minerals Yearbook 2019,” (Part-III) Miner. Rev., vol. 58th Edition, no. september, pp. 1-6, 2020.

M. M. H. Al-tigani, A. A. Mohamed, A. Ahmed, and S. Seifelnasr, “Mineralogical and chemical characterization of disseminated low-grade sudanese chromite ore in gedarif state at Umm Saq a ta-Qala Elnahal,” J. Envi. Anal., vol. 6, no. 3, pp. 1-5, 2019.

T. Çiçek, H. Cengizler, and I. Cöcen, “An efficient process for the beneficiation of a low grade chromite ore,” Trans. Institutions Min. Metall. Sect. C Miner. Process. Extr. Metall., vol. 119, no. 3, pp. 142-146, 2010,

A. A. Seifelnasr, T. Tammam, and A. Z. M. Abouzeid, “Gravity concentration of sudanese chromite ore using laboratory shaking table,” Physicochem. Probl. Miner. Process., vol. 48, no. 1, pp. 271-280, 2012.

S. K. Tripathy, V. Singh, and Y. Ramamurthy, “Improvement in Cr:Fe Ratio of indian chromite ore for ferro chrome production,” Int. J. M ining Eng. M ineral Process., vol. 1, no. 3, pp. 101-106, 2012,

N. Aslan, “Multi-objective optimization of some process parameters of a multi-gravity separator for chromite concentration,” Sep. Purif. Technol., vol. 64, no. 2, pp. 237-241, 2008.

G. . Özkan and B. İpekoğlu, “Concentration studies on chromite tailings by multi gravity separator,” in International Mining Congress and Exhibition of Turkey, 2001, pp. 765-768.

G. P. Gallios, E. A. Deliyanni, E. N. Peleka, and K. A. Matis, “Flotation of chromite and serpentine,” Sep. Purif. Technol., vol. 55, no. 2, pp. 232-237, 2007.

A. A. . S. Seifelnassr, and T. A. K. Tamam, “Flotation behavior of sudanese chromite ores,” JES. J. Eng. Sci., vol. 39, no. 3, pp. 649-661, 2011.

B. Beklioglu, and A. Arol, “Selective flocculation behavior of chromite and serpentine,” Sel. flocculation Behav. chromite serpentine, vol. 38, no. 1, pp. 103-112, 2004.

N. C. Karmakar, B. S. Sastry, and R. P. Singh, “Flocculation of chromite ore fines suspension using polysaccharide based graft copolymers,” Bull. Mater. Sci., vol. 25, no. 6, pp. 477-478, 2002.

M. M. H. Al-tigani, A. A. Mohamed, A. Abdullah, and S. Seifelnasr, “Beneficiation of disseminated low-grade sudanese chromite ore in gedarif state at umm saqata-qala elnahal,” J. Envi. Anal., vol. 6, no. 4, pp. 1-7, 2019.

A. M. Rao, R. K. Rath, M. K. Mohanta, B. Dey, M. Sahoo, and R. Singh, “Beneficiation Studies on Low Grade Chromite Ores using Multi Gravity Separator,” pp. 76-81, 2017.

S. Inal and I. Alp, “Beneficiation of Magnetite Rich Chromite Ore with Magnetic Separation,” in Proceedings of 14th International Mineral Processing Symposium– Kuşadası, Turkey, 2014, pp. 135-140.

S. K. Tripathy, P. K. Banerjee, and N. Suresh, “Magnetic separation studies on ferruginous chromite fine to enhance Cr : Fe ratio Magnetic separation studies on ferruginous chromite fine to enhance Cr : Fe ratio,” Int. J. Miner. Metall. Mater., vol. 22, no. March, p. 212, 2015.

Y. R. Murthy, S. K. Tripathy, and C. R. Kumar, “Chrome ore beneficiation challenges & opportunities - A review,” Miner. Eng., vol. 24, no. 5, pp. 375-380, 2011.

O. Bayat, I. Cocen, and T. Cicek, "Concentration of adana-aladag chromite tailings by gravitational methods," in VIII Balkan Mineral Processing Conference , 1999, pp. 91-98.

Y. R. Murthy, and S. K. Tripathy, “Process optimization of a chrome ore gravity concentration plant for sustainable development,” J. South. African Inst. Min. Metall., vol. 120, no. 4, pp. 261-268, 2020.

I. B. Can, B. Özsoy, and L. Ergün, “Developing an optimum beneficiation route for a low-grade chromite ore,” Physicochem. Probl. Miner. Process., vol. 55, no. 4, pp. 865-878, 2019.

G. A. Sen, “Application of full factorial experimental design and response surface methodology for chromite beneficiation by Knelson concentrator,” Minerals, vol. 6, no. 1, 201.

S. K. Das, “Quantitative mineralogical characterization of chrome ore beneficiation plant tailing and its beneficiated products,” Int. J. Miner. Metall. Mater., vol. 22, no. 4, pp. 335-345, 201.

A. K. Das et al., “Processing of low-grade chromite ore for ferroalloy production: A case study from ghutrigaon, odisha, india,” Trans. Indian Inst. Met., vol. 73, no. 9, pp. 2309-2320, 2020.

A. Falconer, "Gravity separation: Old techmique/new methords," Phys. Sep. Sci. Engin., vol. 12, no. 1, pp. 31-48, 2003.

B. K. Sarkar, M. G. Dastidar, R. Dey, G. C. Das, S. Chowdhury, and D. K. Mahata, “Optimization of reduction parameters of quenched titaniferous magnetite ore by boiler grade coal using box–behnken design,” J. Inst. Eng. Ser. D, 2019.

L. Wu, K. L. Yick, S. P. Ng, and J. Yip, “Application of the Box-Behnken design to the optimization of process parameters in foam cup molding,” Expert Syst. Appl., vol. 39, no. 9, pp. 8059-8065, 2012.

M. I. Sabela, S. Kanchi, B. Ayyappa, and K. Bisetty, “A box-behnken design and response surface approach for the simultaneous determination of chromium (III) and (VI) using catalytic differential pulse polarography,” Int. J. Electrochem. Sci., vol. 9, no. 12, pp. 6751-6764, 2014.

S. A. Pasma, R. Daik, M. Y. Maskat, and O. Hassan, “Application of box-behnken design in optimization of glucose production from oil palm empty fruit bunch cellulose,” Int. J. Polym. Sci., vol. 2013, 201.

S. K. Tripathy, Y. Ramamurthy, and V. Singh, “Recovery of chromite values from plant tailings by gravity concentration,” J. Miner. Mater. Charact. Eng., vol. 10, no. 01, pp. 13-25, 2011

C. Biswas, S. Samanta, A. Bhattacharyya, M. G. Chaudhuri, and R. Dey, “Statistical optimisation parameter for lean grade self-reducing nuggets by surface response modelling to produce pig iron,” Trans. Institutions Min. Metall. Sect. C Miner. Process. Extr. Metall., vol. 126, no. 3, pp. 172-181, 2017.

E. Kilickap, “Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite,” Expert Syst. Appl., vol. 37, no. 8, pp. 6116-6122, 2010.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.