Durability of precast prestressed concrete pile in exposure severe environment

DOI:

https://doi.org/10.55713/jmmm.v35i1.1917Keywords:

Durability, Corrosion, Precast Prestressed Concrete Pile, sacrificial anodeAbstract

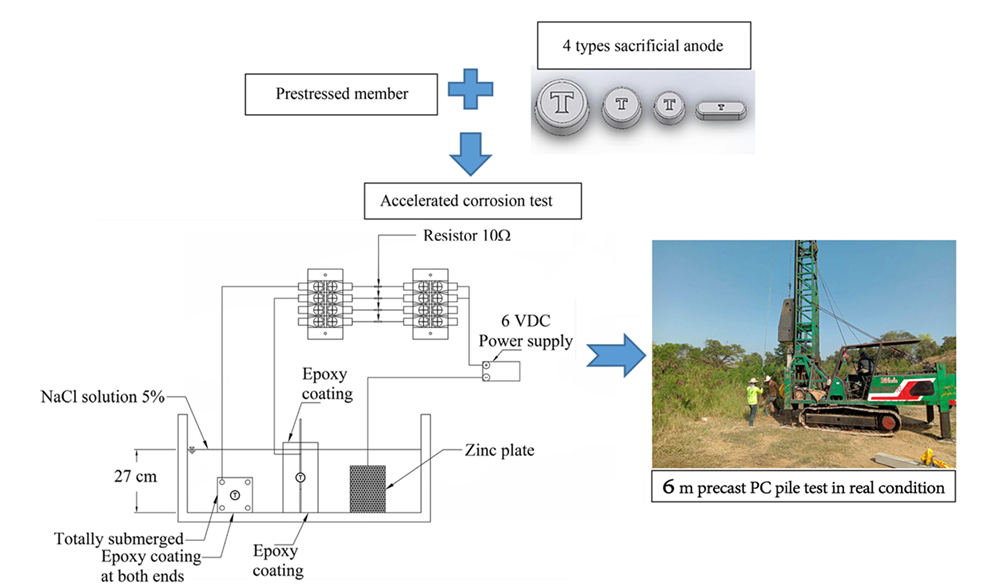

This research project focuses on studying the corrosion resistance of precast prestressed concrete (PC) piles under severe conditions. All PC and non-PC samples were cast using Portland cement type III. The samples included 1 m and 6 m length specimens. To evaluate the effectiveness of corrosion prevention, Sacrificial Anode Cathodic Protection (SACP) was installed in the specimens. Various durability properties of concrete were tested, including chloride permeability, concrete resistivity, and half-cell potential. For short-term effects, an electrical accelerated condition was conducted for the 1 m specimens, which were submerged in a 5% sodium chloride solution by weight. Experimental studies were carried out to evaluate the 100 mV polarization shift criterion for confirming the effectiveness of SACP in arresting the progress of corrosion in steel. In addition, for long-term effects and under more realistic conditions, 6 m full-scale PC specimens were installed in a high salinity area to evaluate durability and corrosion behavior. Four different types of sacrificial anodes were used to evaluate durability and corrosion behavior, and corrosion current assessments were closely monitored. The findings from these studies provide vital parameters for the repair and maintenance process, with the aim of minimizing structural loss. The results of this study are intended to guide the decision-making process for developing effective repair strategies.

Downloads

References

P. Ghods, O. B. Isgor, and M. Pour-Ghaz, “A practical method for calculating the corrosion rate of uniformly depassivated reinforcing bars in concrete,” Materials and Corrosion, vol. 58, no. 4, pp. 265-272 2007. DOI: https://doi.org/10.1002/maco.200604010

G. Koch, J. Varney, N. Thompson, O. Moghissi, M. Gould, and J. Payer, International Measures of Prevention, Application, and Economics of Corrosion Technologies Study, NACE Impact Report, 216 pages, 2016.

R. B. Polder, W. H. A. Peelen, B. T. J. Stoop, and E. A. C. Neeft, “Early stage beneficial effects of cathodic protection in concrete structures”, Materials and Corrosion, vol. 62, no. 2, pp. 105-110, 2011. DOI: https://doi.org/10.1002/maco.201005803

J. Xu, and W. Yao, “Current distribution in reinforced concrete cathodic protection system with conductive mortar overlay anode,” Construction and Building Materials, vol. 23, no.6, pp. 2220-2226, 2009.

A. Byrne, N. Holmes, and B. Norton, “State-of-the-art review of cathodic protection for reinforced concrete structures”, Magazine Concrete Research,” vol. 68, pp. 1-14, 2016. DOI: https://doi.org/10.1680/jmacr.15.00083

P. Pedeferri, “Cathodic protection and cathodic prevention,” Construction and Building Materials, vol. 10, pp. 391-402, 1996. DOI: https://doi.org/10.1016/0950-0618(95)00017-8

L. Bertolini, F. Bolzoni, M. Gastaldi, T. Pastore, P. Pedeferri, and E. Redaelli, “Effects of cathodic prevention on the chloride threshold for steel corrosion in concrete,” Electrochimica. Acta, vol. 54, pp. 1452-1463, 2009. DOI: https://doi.org/10.1016/j.electacta.2008.09.033

J. Bennett, J. B. Bushman, J. Costa, and P. Noyce, “Field application of performance enhancing chemicals to metallized zinc anodes,” Corrosion, No. NACE-00790, 2000.

J. Xu, and W. Yao, ‘Current distribution in reinforced concrete cathodic protection system with conductive mortar overlay anode,” Construction and Building Materials, vol. 23, pp. 2220-2226, 2009. DOI: https://doi.org/10.1016/j.conbuildmat.2008.12.002

P. Marcassoli, A. Bonetti, L. Lazzari, and M. Ormellese, “Modeling of potential distribution of subsea pipeline under cathodic protection by finite element method,” Materials and Corrosion, vol. 66, pp. 619-626, 2015. DOI: https://doi.org/10.1002/maco.201407738

N. Khomwan, and P. Mungsantisuk, “Startup Thailand: A new innovation sacrificial anode for reinforced concrete structures,” Engineering Journal, vol. 23, no. 4, pp. 235-261, 2019. DOI: https://doi.org/10.4186/ej.2019.23.4.235

Highways England, CS 462, Repair and management of deteriorated concrete highway structures, 2020.

N. Krishnan, D. K. Kamde, Z. D. Veedu, R. G. Pillai, D. Shah, and V. Rajendran, “Long-term performance and life-cycle-cost benefits of cathodic protection of concrete structures using galvanic anodes”, Journal of Building Engineering, vol. 42, p. 102467, 2021. DOI: https://doi.org/10.1016/j.jobe.2021.102467

D. K. Kamde, K. Manickam, R. G. Pillai, and G. Sergi, “Long-term performance of galvanic anodes for the protection of steel reinforced concrete structures”, Journal of Building Engineering, vol. 42, p. 103049, 2021. DOI: https://doi.org/10.1016/j.jobe.2021.103049

EN ISO 12696 Standards, “Cathodic Protection of Steel in Concrete,” 54 pages, 2022.

Build NT 356, “Concrete, repairing materials and protective coating: embedded steel method, chloride permeability,” NT Build, 356, Nordtest, Espoo, Finland, 1989.

ASTM C876-22b, “Standard test method for corrosion potentials of uncoated reinforcing steel in concrete, Annual Book of ASTM Standards,” 8 pages, 2022.

ASTM G1, “Standard practice for preparing, cleaning, and evaluating corrosion test specimens, Annual Book of ASTM Standards,” 9 pages, 2017.

M. Romanoff, Underground Corrosion, National Bureau of Standards Circular 579, April 1957.

N. D. Tomashov, and Y. N. Mikhailovsky, “Corrosivity of Soil,” Corrosion, vol. 15, no. 2, pp. 41-46, 1959. DOI: https://doi.org/10.5006/0010-9312-15.2.41

National Bureau of Standards, “Study of causes and effects of underground corrosion,” Journal AWWA, Dec., pp. 1581-1588, 1958. DOI: https://doi.org/10.1002/j.1551-8833.1958.tb20739.x

BS EN 12501-12502, “Protection of metallic materials against corrosion. Corrosion likelihood in soil, Part 2: Low alloyed and unalloyed ferrous materials” European Standard, 2003.

American Concrete Institute, ACI manual of concrete practice. Part 3. Farmington Hills, MI. 2004.

M. Maslehuddin, M. M. Al-Zahrani, M. Ibrahim, M. H. Al-Mehthel, and S. H. Al-Idi, “Effect of chloride concentration in soil on reinforcement corrosion,” Construction and Building Materials, vol. 21, no. 8, pp. 1825-1832, 2007. DOI: https://doi.org/10.1016/j.conbuildmat.2006.05.019

S. K. Al-Mamoori, L. A. J. Al-Maliki, K. El-Tawel, H. M. Hussain, “Chloride, calcium carbonate and total soluble salts contents distribution for An-Najaf and Al-Kufa Cities’ soil by using GIS,” Geotechnical and Geological Engineering, vol. 37, no. 3, pp. 2207-2225, 2019. DOI: https://doi.org/10.1007/s10706-018-0754-x

S. H. Kosmatka, and M. L. Wilson, Design and Control of Concrete Mixtures. Fifteenth Edition, Engineering Bulletin 001.15, Portland Cement Association, Skokie, IL, 444 pages, 2011.

P. K. Mehta, Concrete: Structure, Properties and Materials. Prentice Hall, Englewood Cliffs, NJ. 1986

D. Stark, Performance of Concrete in sulfate Environments, PCA RD129, Portland Cement Association, Skokie, IL, 28 pages, 2002.

H. Haynes, R. O’Neill, M. Neff, and P. K. Mehta, “Concrete deterioration from physical attack by salts,” Concrete International, vol. 18, no. 1, pp. 63-68., 1996

H. Haynes, and M. T. Bassouni, “Physical salt attack on concrete,” Concrete International, vol. 33, no. 11, pp. 38-42, 2011.

ASTM C39/39M-21, “Standard test method for compressive strength of cylindrical concrete specimens, Annual Book of ASTM Standards,” 8 pages, 2021.

ASTM C1202-19, “Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration, Annual Book of ASTM Standards,” 8 pages, 2019.

AASHTO T358, “Standard method of test for surface resistivity indication of concrete’s ability to resist chloride ion penetration,” American Association of State Highway and Transportation Officials, Washington, DC, 2015.

R. H. Faraj, A. F. H. Sherwani, and A Daraei. “Mechanical, fracture and durability properties of self-compacting high strength concrete containing recycled polypropylene plastic particles,” Journal of Building Engineering, vol. 25, 2019. DOI: https://doi.org/10.1016/j.jobe.2019.100808

S. Bahij, S. Omary, F. Feugeas, and A. Faqiri, “Fresh and hardened properties of concrete containing different forms of plastic waste –A review,” Waste Manage, vol. 113, pp. 157-175, 2020. DOI: https://doi.org/10.1016/j.wasman.2020.05.048

P. O. Awoyeraa, and A. Adesinab, “Plastic wastes to construction products: Status, limitations and future perspective,” Case Studies in Construction Materials, vol. 12, 2020. DOI: https://doi.org/10.1016/j.cscm.2020.e00330

G. Madhu, H. Bhunia, P. K. Bajpai, and V. Chaudhary, “Mechanical and morphological properties of high density polyethylene and poly-lactase blends,” Journal of Polymer Engineering, vol. 34, no. 9, pp. 813-821, 2014. DOI: https://doi.org/10.1515/polyeng-2013-0174

A. Chini, L. Muszynski, and J. Hicks, “Determination of acceptance permeability characteristics for performance-related specifications for portland cement concrete,” Publication BC 354-41, University of Florida, Gainesville, FL, 162 pp., 2003.

R. Kessler, R. Powers, E. Vivas, M. Paredes, and Y. Virmani, “Surface resistivity as an indicator of concrete chloride penetration resistance,” Concrete Bridge Conference, St. Louis, MO, May 4-7, 2008.

T. Rupnow, and P. J. Icenogle, Evaluation of Surface Resistivity Measurements as an Alternative to the Rapid Chloride Permeability Test for Quality Assurance and Acceptance, Louisiana Transportation Research Center, Project Report, Baton Rouge, LA, July, 68 pp., 2011.

E. W. Ryan,, Comparison of Two Methods for the Assessment of Chloride Ion Penetration in Concrete: A Field Study, master’s thesis, University of Tennessee, Knoxville, TN, pp. 42-43., 2011.

R. Spragg, Y. Bu, K. Snyder, D. Bentz, and J. Weiss, “Electrical Testing of Cement-Based Materials: Role of Testing Techniques, Sample Conditioning, and Accelerated Curing,” Publication FHWA/IN/JTRP-2013/28, Joint Transportation Research Program, Indian Department of Transportation and Purdue University, West Lafayette, IN, pp. 1-16., 2013. DOI: https://doi.org/10.5703/1288284315230

R. Spragg, J. Castro, T. Nantung, M. Parades, and W. Weiss, “Variability analysis of the bulk resistivity measured using concrete cylinders,” SPR-3509, FHWA/IN/JTRP-2011, Joint Transportation Research Program, Washington, DC, pp. 1-8., 2011.

R. Spragg, C. Villani, K. Snyder, D. Bentz, J. Bullard, and J. Weiss, “Electrical resistivity measurements in cementitious systems: Observations of factors that influence the measurements,” Transportation Research Board, Washington, DC, pp. 90-98, 2013. DOI: https://doi.org/10.3141/2342-11

J. Tanesi, and A. Ardani, “Surface resistivity test evaluation as an indicator for the chloride permeability of concrete,” FHWA Publication No: FHWA-HRT-13-024, Turner-Fairbank Highway Research Center, McLean, VA, 2013.

P. K. Mehta, and P. J. M. Monterio, Concrete. New York: McGraw-Hill; 2006.

J. Bijen, Blast furnace slag cement for durable marine structures. The Netherlands: VNC/BetonPrisma., 1998.

J. Hill, and J. H. Sharp, “The mineralogy and microstructure of three composite cements with high replacement levels,” Cement and Concrete Composites, vol. 24, no. 19, pp. 1-9, 2002. DOI: https://doi.org/10.1016/S0958-9465(01)00041-5

S. Hu, X. Guan, and Q. Din, “Research on optimizing components of microfine highperformance composite cementitious materials,” Cement and Concrete Composites, vol. 32, no. 12, pp. 1871-1875, 2002. DOI: https://doi.org/10.1016/S0008-8846(02)00803-7

O. Sengul, and O. E. Gjørv, “Effect of binder system on the resistance of concrete against chloride penetration” 8th international symposium on utilization of high-strength and high-performance concrete, Tokyo, pp. 330-335, 2008.

J. A. Hartell, and C. Shults, Surface Resistivity Testing for Quality Control of Concrete Mixtures, Southern Plains Transportation Center United States. Department of Transportation. University Transportation Centers (UTC) Program, Report No. SPTC 17.1-07, pp. 50, 2018.

ACI Committee 201, “Guide to Durable Concrete, American Concrete Institute,” 2016.

A. Scott, and M. Alexander, “Effect of supplementary cementitious materials (binder type) on the pore solution chemistry and the corrosion of steel in alkaline environments,” Cement and Concrete Research, vol. 89, pp. 45-55, 2016. DOI: https://doi.org/10.1016/j.cemconres.2016.08.007

C. C. Ferraro, J. M. Paris, T. Townsend, and M. Tia, Evaluation of Alternative Pozzolanic Materials for Partial Replacement of Portland Cement in Concrete”, FDOT Final Report, 345 pages, 2016.

B. Lothenbach, K. Scrivener, and R. Hooton, “Supplementary cementitious materials,” Cement and Concrete Research, vol. 41, no. 12, pp. 1244-1256, 2011. DOI: https://doi.org/10.1016/j.cemconres.2010.12.001

H. F. Taylor, Cement Chemistry, second ed., Thomas Telford, 1997. DOI: https://doi.org/10.1680/cc.25929

J. M. Paris, J. G. Roessler, C. C. Ferraro, H. D. DeFord, and T. G.

Townsend, “A review of waste products utilized as supplements to Portland cement in concrete”, Journal of Cleaner Prodroduction, vol. 121, pp. 1-18, 2016. DOI: https://doi.org/10.1016/j.jclepro.2016.02.013

W. Yodsudjai, and S. Rakvanich, “Experimental study on anode life and effective distance of sacrificial cathodic protection in reinforced concrete,” Engineering Journal, vol. 24 no. 6, pp. 159-169, 2020. DOI: https://doi.org/10.4186/ej.2020.24.6.159

J.-M. Ha, J.-A. Jeong, and C. Jin, “Development of conductive mortar for efficient sacrificial anode cathodic protection of reinforced concrete structures—Part 1: Laboratory experiments,” Applied Science, vol. 12, no. 23, pp. 1-14, 2022. DOI: https://doi.org/10.3390/app122312056

A. E. A. Thybo, Corrosion-induced Cracking in Reinforced Concrete Structures -a numerical study. Technical University of Denmark, Department of Civil Engineering. B Y G D T U. Rapport No. 397, 2018.

G. Sergi, “Ten-year results of galvanic sacrificial anodes in steel reinforced concrete,” Materials and Corrosion, vol. 62, no. 2, pp. 98-104, 2011 DOI: https://doi.org/10.1002/maco.201005707

J.-M. Ha, J.-A. Jeong, and C. Jin, “Development of conductive

mortar for efficient sacrificial anode cathodic protection of reinforced concrete structures—Part 2: Four-year performance evaluation in bridges,” Applied Science, vol. 14, no. 5, pp.1-16, 2024. DOI: https://doi.org/10.3390/app14051797

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.