Utilization of rubber tree bark as a carbon source for electric arc furnace steelmaking: Carbon/slag interaction at 1550℃

DOI:

https://doi.org/10.55713/jmmm.v32i4.1539คำสำคัญ:

Rubber tree bark, Agricultural waste, Carbon/slag interaction, Slag foamingบทคัดย่อ

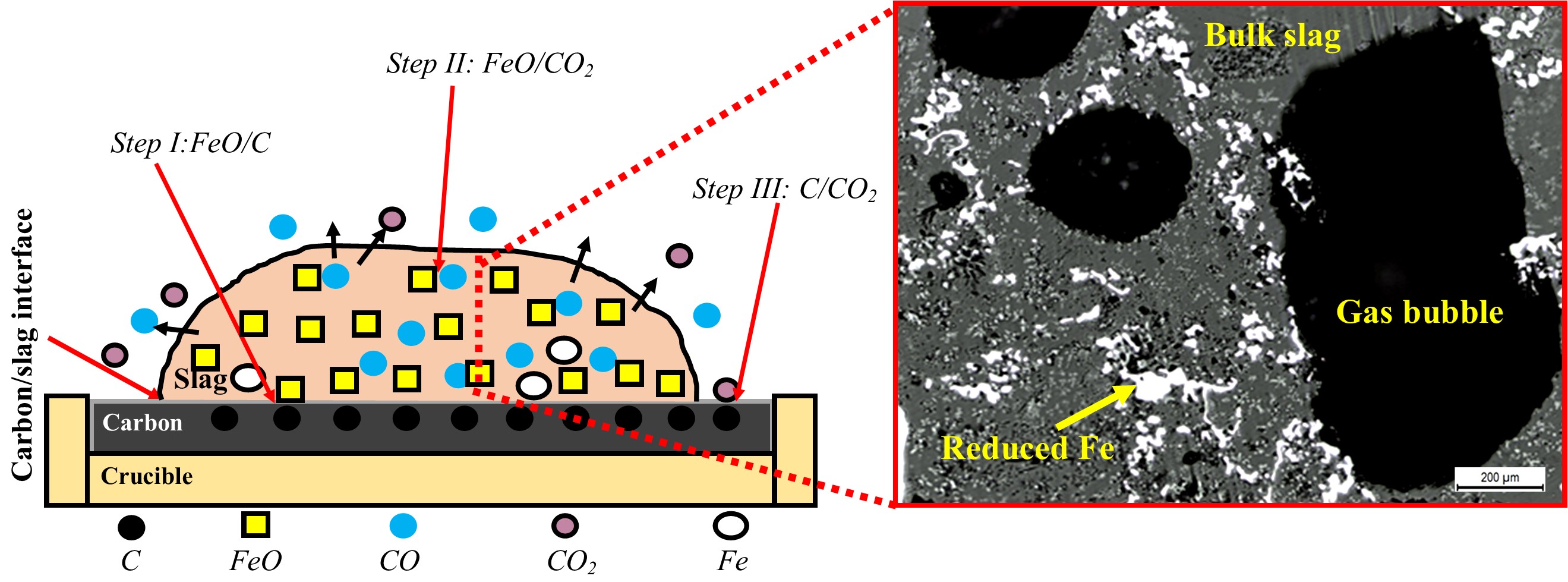

Rubber tree bark (RTB) is a biomass that consists of wood and rubber parts, with high volatile and ash contents. This research reports the utilization of RTB as a carbon source in Electric Arc Furnace steelmaking processes. RTB was mixed with coal at a ratio of 1:1 by weight, and heated at 1000℃ under an argon atmosphere for 1 h. The chars were brought to contact with Electric Arc Furnace slag (37.86 wt% Fe2O3) at 1550℃ for 15 min to investigate their interaction and compared to coal. Coal showed short slag foaming behavior with a foaming time of 4 min, while complete FeO reduction was seen thereafter with the DOM of 65.14%. For RTB, slag foaming sustains over 15 min, but small extent of FeO reduction was observed with the DOM of 42.57%. For the Mixture, foaming time was 8 min, while iron droplets were seen since 8 min with the DOM of 54.63%. It was likely that interaction between the mixture and slag was due to the synergistic effect between coal and RTB. This research unlocks the potential of using RTB biomass for steelmaking process and the consumption of coal could be deducted by up to 50 wt%.

Downloads

เอกสารอ้างอิง

S. Hara, and K. Ogino, “Slag-foaming phenomenon in pyro-metallurgical processes,” Iron and Steel Institute of Japan, vol. 32, no. 2, pp. 81-86, 1992.

J. Heo, and J. Park, “Effect of Slag Composition on Dephosphorization and Foamability in the Electric Arc Furnace Steelmaking Process: Improvement of Plant Operation,” Metallurgical and Materials Transactions B, vol. 52, no. 6, pp. 3613-3623, 2021.

K. Ito, and R.J. Fruehan, “Study on the Foaming of CaO-SiO2-FeO Slags. Part I:Foaming Parameters and Experimental Results,” Metallurgical Transactions B, vol. 20, no. 4, pp. 509-514, 1989.

K. Ito, and R.J. Fruehan, “Study on the Foaming of CaO-SiO2-FeO Slags. Part II: Dimensional analysis and foaming in iron and steelmaking processes”Metallurgical Transactions B, vol. 20, no. 4, pp. 515-521, 1989.

Y. Zhang, and R.J. Fruehan, “Effect of the bubble size and chemical reactions on slag Foaming," Metallurgical and Materials Transactions B, vol. 26, pp. 803-812, 1995.

M. Rahman, R. Khanna, V. Sahajwalla, and P. O’Kane, “The influence of ash impurities on interfacial reactions between carbonaceous materials and EAF slag at 1550ºC,” Iron and Steel Institute of Japan, vol. 49, no. 3, pp. 329-336, 2009.

X. Huang, K. Wing, L. Giroux, and M. Duchesne, “Carbonaceous material properties and their interactions with slag during electric arc furnace steelmaking,” Metallurgical Transactions B, vol. 50, pp. 1387-1398, 2019.

V. Sahajwalla, M. Rahman, R. Khanna, N. Saha-Chaudhury, P. O’Kane, C. Skidmore, and D. Knights, “Recycling waste plastics in EAF steelmaking: Carbon/slag interactions of HDPE-Coke blends,” Steel Research International, vol. 80, no. 8, pp. 535-543, 2009.

M. Zaharia, V. Sahajwalla, R. Khanna, P. Koshy, and P. O’Kane, “Carbon/slag interactions between coke/rubber blends and EAF slag at 1550℃,” Iron and Steel Institute of Japan, vol. 49, no. 10, pp. 1513-1521, 2009.

S. Kongkarat, R. Khanna, P. Koshy, P. O’Kane, and V. Sahajwalla, “Recycling Waste Polymers in EAF Steelmaking: Influence of Polymer Composition on Carbon/Slag Interactions,” Iron and Steel Institute of Japan, vol. 52, no. 3, pp. 385-393, 2012.

J. R. Dankwah, P. Koshy, N. Saha-Chaudhury, P. O’Kane, C. Skidmore, D. Knights, and V. Sahajwalla, “Reduction of FeO in EAF steelmaking slag by metallurgical coke and waste plastics blends,” Iron and Steel Institute of Japan, vol. 51, no. 3, pp. 498-507, 2011.

J. R. Dankwah, P. Koshy, P. O’Kane, and V. Sahajwalla, “Reduction of FeO in EAF steelmaking slag by blends of metallurgical coke and end-of-life tyre,” Steel Research International, vol. 83, no. 8, pp. 766-774, 2009.

T. Matsumura, M. Ichida, T. Nagasaka, and K. Kato, “Carbonization behavior of woody biomass and resulting metallurgical coke properties,” Iron and Steel Institute of Japan, vol. 48, pp. 572-577, 2008.

Y. Ueki, Y. Nunome, R. Yoshiie, I. Naruse, Y. Nishibata, and S. Aizawa, “Effect of woody biomass addition on coke properties,” Iron and Steel Institute of Japan, vol. 11, pp. 2454-2460, 2014.

N. Yunos, M. Zaharia, M. Asri idris, D. Nath, R. Khanna, and V. Sahajwalla,“Recycling agricultural waste from palm shells during electric arc furnace steelmaking,” Energy&Fuels, vol. 26, pp. 278, 2012.

M. C. Baganiti, T. Kan, T. J. Evans, and V. Strezov, “Iron ore reduction by biomass volatiles,” Journal of Sustainable Metallurgy, vol. 7, no. 1, pp. 215-226, 2021.

B. E. Pretorius, and R. C. Carlisle, “Foaming slag fundamental and their application to electric furnace steelmaking,” Iron and Steelmaker, vol. 26, pp. 79-88, 1999.

R. J. Fruehan, Ed., The making, shaping and treating of steel. Pittsburgh: The Association of Iron and Steel Engineers, 1998.

K.C. Mills, and S. Sridhar, “Viscosities of iron and steelmaking slag ironmaking and steelmaking,” Steel Research International, vol. 26, no. 4, pp. 262-268, 1999.

M. Rahman, “Fundamental investigation of slag/carbon interactions in electric arc furnace steelmaking process,” Ph.D dissertation, School of Materials Science and Engineering, University of New South Wales, Sydney, 2010.

S. Kongkarat, and J. Khumpa, “Utilization of rubber tree bark for reduction of mill scale at 1550℃: Implication for sustainable wastes recycling in steelmaking Process,” Metals, vol. 11, pp. 1738, 2021. 2010.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.