Hot corrosion behavior of Mg\(_{2}\)SiO\(_{4}\) ceramic exposed to molten Na\(_{2}\)SO\(_{4}\) at 900℃ to 1100℃

DOI:

https://doi.org/10.55713/jmmm.v34i1.1777คำสำคัญ:

Forsterite, Thermal barrier, Hot corrosion, Molten saltบทคัดย่อ

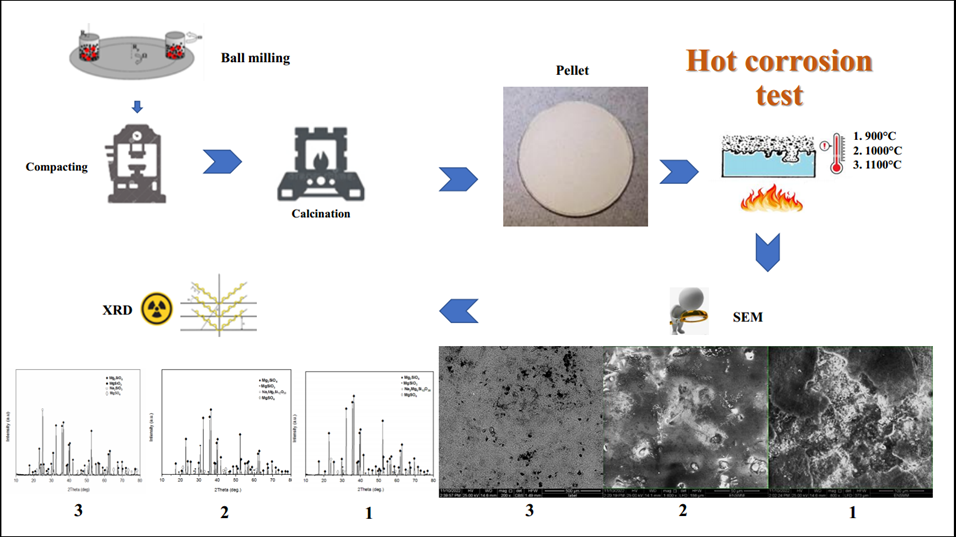

Thermal barriers are used as protective coating for critical components working at high temperature of gas turbines. Forsterite (Mg2SiO4) ceramic is proposed by researchers as a novel thermal barrier coating (TBC), due to its low thermal conductivity and good thermal expansion. Hot corrosion results from the molten salts effect on the TBC’s surface, accumulated during the combustion processes. In this study, Mg2SiO4 samples were exposed to Na2SO4 molten salt at 900℃, 1000℃ and 1100℃ for 6 h in air. Samples were investigated and compared using scanning electron microscope (SEM) and X-Ray diffractometer (XRD). MgSO4 was the predominant corrosion product observed on the surface of the samples. Na2Mg5Si12O30 was also observed at 1000℃ and 1100℃, and Na2SiO3 appeared only on sample treated at 900℃.

Downloads

เอกสารอ้างอิง

S. Chen, X. Zhou, W. Song, J. Sun, H. Zhang, J. Jiang, L. Deng, S. Dong, and X. Cao, “Mg2SiO4 as a novel thermal barrier coating material for gas turbine applications,” Journal of the European Ceramic Society, vol. 39, pp. 2397-2408, 2019.

M. H. Fathi and M. Kharaziha, “Mechanically activated crystallization of phase pure nanocrystalline forsterite powders,” Materials Letters, vol. 62, no. 27, pp. 4306-4309, 2008.

S. Ni, L. Chou, and J. Chang, “Preparation and characterization of forsterite (Mg2SiO4) bioceramics,” Ceramics International, vol. 33, no. 1, pp. 83-88, 2007.

S. Ni, J. Chang, and L. Chou, “In vitro studies of novel CaO–SiO2–MgO system composite bioceramics,” Journal of Materials Science: Materials in Medicine, vol. 19, no. 1, pp. 359-367, 2007.

N. P. Padture, M. Gell, and E. H. Jordan, “Thermal barrier coatings for gas-turbine engine applications,” Science, vol. 296, no. 5566, pp. 280-284, 2002.

R. Vaßen, F. Cernuschi, G. Rizzi, A. Scrivani, N. Markocsan, L. Östergren, A. Kloosterman, R. Mevrel, J. Feist, and J. Nicholls, “Recent activities in the field of thermal barrier coatings including burner rig testing in the European Union,” Advanced Engineering Materials, vol. 10, no. 10, pp. 907-921, 2008.

J. T. DeMasi-Marcin and D. K. Gupta, “Protective coatings in the gas turbine engine,” Surface and Coatings Technology, vol. 68-69, pp. 1-9, 1994.

R. Vassen, X. Cao, F. Tietz, D. Basu, and D. Stöver, “Zirconates as new materials for thermal barrier coatings,” Journal of the American Ceramic Society, vol. 83, no. 8, pp. 2023-2028, 2004.

Z.-G. Liu, J.-H. Ouyang, and Y. Zhou, “Influence of gadolinia on thermal expansion property of ZrO2 – 4.5 mol% Y2O3 ceramics,” Journal of Alloys and Compounds, vol. 473, no. 1-2, 2009.

X. H. Zhong, Y. M. Wang, Z. H. Xu, Y. F. Zhang, J. F. Zhang, and X. Q. Cao, “Hot-corrosion behaviors of overlay-clad yttria-stabilized zirconia coatings in contact with vanadate–sulfate salts,” Journal of the European Ceramic Society, vol. 30, no. 6, pp. 1401-1408, 2010.

N. Wu, Z. Chen, and S. X. Mao, “Hot corrosion mechanism of composite alumina/yttria-stabilized zirconia coating in molten sulfate-vanadate salt,” Journal of the American Ceramic Society, vol. 88, no. 3, pp. 675-682, 2005.

T. S. Sidhu, R. D. Agrawal, and S. Prakash, “Hot corrosion of some superalloys and role of high-velocity oxy-fuel spray coatings—a review,” Surface and Coatings Technology, vol. 198, no. 1-3, pp. 441-446, 2005.

H. Dong, D. Wang, Y. Pei, H. Li, P. Li, and W. Ma, “Optimization and thermal cycling behavior of La2Ce2O7 thermal barrier coatings,” Ceramics International, vol. 39, no. 2, pp. 1863-1870, 2013.

S. Li, Z.-G. Liu, and J.-H. Ouyang, “Growth of YbVO4 crystals evolved from hot corrosion reactions of Yb2Zr2O7 against V2O5 and Na2SO4+V2O5,” Applied Surface Science, vol. 276, pp. 653-659, 2013.

B. R. Marple, J. Voyer, M. Thibodeau, D. R. Nagy, and R. Vassen, “Hot corrosion of lanthanum zirconate and partially stabilized zirconia thermal barrier coatings,” Journal of Engineering for Gas Turbines and Power, vol. 128, no. 1, pp. 144-152, 2004.

L. Guo, C. Zhang, M. Li, W. Sun, Z. Zhang, and F. Ye, “Hot corrosion evaluation of Gd2O3-Yb2O3 co-doped Y2O3 stabilized ZrO2 thermal barrier oxides exposed to Na2SO4+V2O5 Molten Salt,” Ceramics International, vol. 43, no. 2, pp. 2780-2785, 2017.

X. Q. Cao, R. Vassen, and D. Stoever, “Ceramic materials for thermal barrier coatings,” Journal of the European Ceramic Society, vol. 24, no. 1, pp. 1-10, 2004.

C. G. Levi, “Emerging materials and processes for thermal barrier systems,” Current Opinion in Solid State and Materials Science, vol. 8, no. 1, pp. 77-91, 2004.

W. Ma, D. Mack, R. Vaßen, and D. Stöver, “Perovskite-type strontium zirconate as a new material for thermal barrier coatings,” Journal of the American Ceramic Society, vol. 91, no. 8, pp. 2630-2635, 2008.

C. Friedrich, R. Gadow, and T. Schirmer, “Lanthanum hexaaluminate ‒ A new material for atmospheric plasma spraying of advanced thermal barrier coatings,” Journal of Thermal Spray Technology, vol. 10, no. 4, pp. 592-598, 2001.

G. Li, and G. Yang, “Understanding of degradation-resistant behavior of nanostructured thermal barrier coatings with bimodal structure,” Journal of Materials Science & Technology, vol. 35, no. 3, pp. 231-238, 2019.

R. Vassen, X. Cao, F. Tietz, D. Basu, and D. Stöver, “Zirconates as new materials for thermal barrier coatings,” Journal of the American Ceramic Society, vol. 83, no. 8, pp. 2023-2028, 2004.

R. A. Rapp, and Y.-S. Zhang, “Hot corrosion of materials: fundamental studies,” JOM, vol. 46, no. 12, pp. 47-55, 1994

C. O. Park, and R. A. Rapp, “Electrochemical reactions in molten Na2SO4 at 900°C,” Journal of The Electrochemical Society, vol. 133, no. 8, pp. 1636-1641, 1986.

R. A. Rapp, “Chemistry and electrochemistry of hot corrosion of metals,” Materials Science and Engineering, vol. 87, pp. 319-327, 1987

F. Tavangarian, and R. Emadi, “Synthesis of nanocrystalline forsterite (Mg2SiO4) powder by combined mechanical activation and thermal treatment,” Materials Research Bulletin, vol. 45, no. 4, pp. 388-391, 2010.

J. Takahashi, Y. Kawai, and S. Shimada, “Hot corrosion of cordierite ceramics by Na‒ and K‒ salts,” Journal of the European Ceramic Society, vol. 18, no. 8, pp. 1121-1129, 1998.

X. Chen, X. Cao, B. Zou, J. Gong, and C. Sun, “Corrosion of lanthanum magnesium hexaaluminate as plasma-sprayed coating and as bulk material when exposed to molten V2O5-containing salt,” Corrosion Science, vol. 91, pp. 185-194, 2015.

Y. Hou, H. Zhu, S. Yan, S. Wang, and B. Hu, “Growth of Cr4+: Mg2SiO4 crystal by Czochralski method,” SPIE Proceedings, vol. 1863, pp. 84-89, 1993.

S. Chen, W. Song, X. Zhou, H. Zhang, X. Zhou, Y. Tu, J. Yuan, S. Dong, and X. Cao, “Hot corrosion of Mg2SiO4 ceramics exposed to V2O5 at temperatures of 700℃ to 1050°C in air,” Corrosion Science, vol. 159, p. 108114, 2019.

S. Li, Z.-G. Liu, and J.-H. Ouyang, “Hot corrosion of (Sm1−xYbx) 2Zr2O7 (x=0, 0.5, 1.0) ceramics against V2O5 molten salt in air at 800°C,” International Journal of Applied Ceramic Technology, vol. 9, no. 1, pp. 149-158, 2011.

V. Prigiobbe, A. S. Negreira, and J. Wilcox, “Interaction between olivine and water based on density functional theory calculations,” The Journal of Physical Chemistry C, vol. 117, no. 41, pp. 21203-21216, 2013.

A. Soleimani Dorcheh, R. N. Durham, and M. C. Galetz, “Corrosion behavior of stainless and low-chromium steels and IN625 in molten nitrate salts at 600°C,” Solar Energy Materials and Solar Cells, vol. 144, pp. 109-116, 2016.

P. Vadász, B. Plešingerová, J. Briančin, G. Sučik, and D. Medveď, “Interactions in two-phase systems of MgO(s)-(Na2O-SiO2)(l),” Interceram - International Ceramic Review, vol. 68, no. 3, pp. 32-39, 2019.

Q. Y. Wang, Y. F. Zhang, S. L. Bai, and Z. D. Liu, “Micro-structures, mechanical properties and corrosion resistance of hastelloy C22 coating produced by laser cladding,” Journal of Alloys and Compounds, vol. 553, pp. 253-258, 2013.

FactSage (8.2). CRCT–ThermFact and GTT–Technologies. Accessed: Jun. 05, 2023. [Online]. Available: https://www. crct.polymtl.ca/fact/documentation/.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.