Surface characteristics evolution of 316L stainless steel induced by tension loading

DOI:

https://doi.org/10.55713/jmmm.v34i4.1982คำสำคัญ:

316L stainless steel, Plastic deformation, Surface relief, Contact angle, Surface free energyบทคัดย่อ

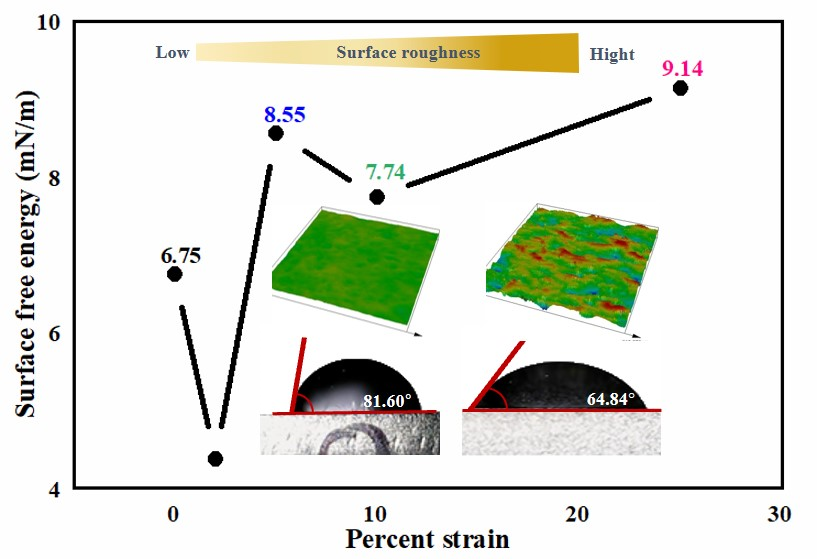

316L stainless steel has been employed as a medical implant material owing to its advantageous biocompatibility and durability. The microstructure and surface characteristics of 316L play a crucial role in implant application. Diverse processing methods were utilized to modify the surface properties of 316L to customize the characteristics of medical devices. Mechanical deformation induces changes in the microstructure and causes changes in surface topography. In this study, we introduced deformation to 316L by applying uniaxial tension at strain values ranging from 2% to 25%. During sample preparation, electrochemical polishing was employed to eliminate the deformed layers generated by mechanical grinding. After the tensile test, a contact angle test was conducted. The surface relief of 316L was examined using three-dimensional (3D) laser scanning microscopy and atomic force microscopy. X-ray diffraction with CuK radiation in the Bragg–Brentano (θ–θ) mode was also employed to identify the phase transformation. It can be concluded that higher strain levels increased surface roughness and the number of slip lines. At higher strain levels, samples exhibited a martensitic transformation, affecting topography changes and the surface free energy. The contact angle measurement results and surface free energy determination showed improved wettability following plastic deformation. Determining the factors that affect surface wettability requires an understanding of the relationship between surface free energy, topography, and surface roughness. Deformation-induced martensite can significantly increase the surface free energy and wettability of 316L stainless steel (SS) by altering strain levels. It is important to consider surface characteristics to understand slip mechanisms at grain boundaries, particularly in cases where surfaces have been electropolished. Nevertheless, the surface also manifested deformation-induced martensitic (DIM) transformation, potentially posing a risk to the passive film and contributing to corrosion, consequently reducing the implant’s lifespan.

Downloads

เอกสารอ้างอิง

S. Wu, S. Altenried, A. Zogg, F. Zuber, K. Maniura-Weber, and Q. Ren, "Role of the surface nanoscale roughness of stainless steel on bacterial adhesion and microcolony formation," ACS omega, vol. 3, no. 6. pp. 6456-6464, 2018. DOI: https://doi.org/10.1021/acsomega.8b00769

L. Susanna, "Surface free energy – what is it and how to measure it?," Biolin Scientific.com. https://www.biolinscientific.com/ blog/how-to-measure-surface-free-energy (accessed Apr. 6, 2020).

S. Cicek, A. Karaca, I. Torun, M.S. Onses, and B. Uzer, "The relationship of surface roughness and wettability of 316L stainless steel implants with plastic deformation mechanisms," Materials Today: Proceedings, vol. 7, pp. 389-393, 2019. DOI: https://doi.org/10.1016/j.matpr.2018.11.100

Y. Tian, O. I. Gorbatov, A. Borgenstam, A. V. Ruban, and P. Hedström, "Deformation microstructure and deformation induced martensite in austenitic Fe-Cr-Ni alloys depending on stacking fault energy," Metallurgical and materials transactions A, vol. 48, no. 1, pp. 1-7, 2017. DOI: https://doi.org/10.1007/s11661-016-3839-2

Z. Zhang, W. Wang, A. N. Korpacz, C. Dufour, Z. J. Weiland, C. R. Lambert, and M. Timko, "Binary liquid mixture contact-angle measurements for precise estimation of surface free energy," Langmuir, vol. 35, no. 38, pp. 12317-12325, 2019. DOI: https://doi.org/10.1021/acs.langmuir.9b01252

A. M, O. Omar, W. Xia, and A. Palmquist, "Dental Implant surfaces – physicochemical properties, biological performance and trends implant dentistry," Implant Dentistry-A Rapidly Evolving Practice, vol. 1, pp.19-56, 2011.

A. Shenoy, "The effect of surface roughness on the fretting corrosion of 316L stainless steel biomaterial surfaces," PhD diss., Syracuse University, 2014.

J. E. Davies, E. Ajami, R. Moineddin, and V. C. Mendes, "The roles of different scale ranges of surface implant topography on the stability of the bone/implant interface," Biomaterials, vol. 34, no. 14, pp. 3535-3546, 2013. DOI: https://doi.org/10.1016/j.biomaterials.2013.01.024

J. P. Hirth, and L. Kubin, "Cross-slip," in Handbook of Dislocations in solids, 2009, pp. 15-17.

P Hedström, "Deformation and martensitic phase transformation in stainless steels,” Ph.D. dissertation, Luleå tekniska universitet, 2007.

M. Montagnat, J. Weiss, J. Chevy, P. Dubal, H. Brunjail, P. Bastie, and J. G. Sevillano, "The heterogeneous nature of slip in ice single crystals deformed under torsion," Philosophical Magazine, vol. 86, no. 27, pp. 4259-4270, 2006. DOI: https://doi.org/10.1080/14786430500452602

S. Mishra, K. Narasimhan, and I. Samajdar, "Deformation twinning in AISI 316L austenitic stainless steel: role of strain and strain path," Materials Science and Technology, vol. 23, no. 9, pp. 1118-1126, 2007. DOI: https://doi.org/10.1179/174328407X213242

N. Eliaz, "Corrosion of metallic biomaterials: A review," Materials, vol. 12, no. 3, p.407, 2019. DOI: https://doi.org/10.3390/ma12030407

A. Nouri, and C. Wen, "Introduction to surface coating and modification for metallic biomaterials," Surface Coating and Modification of Metallic Biomaterials, pp. 3-60, 2015. DOI: https://doi.org/10.1016/B978-1-78242-303-4.00001-6

J. L. Wang, M. H. Huang, X. H. Xi, C. C. Wang, and W. Xu, "Characteristics of nucleation and transformation sequence in deformation-induced martensitic transformation," Materials Characterization, vol. 163, p. 110234, 2020. DOI: https://doi.org/10.1016/j.matchar.2020.110234

N. Solomon, and I. Solomon, "Phase transformation influence on corrosion resistance of AISI 316 austenitic stainless steel," UPB Scientific Bulletin, vol. 72, pp. 197-207, 2010.

F. Ma, K. W. Xu, and P. K. Chu, "Surface-induced structural transformation in nanowires," Materials Science and Engineering, vol. 74, no. 6, pp. 173-209, 2013. DOI: https://doi.org/10.1016/j.mser.2013.05.001

Q. Zu, Y. F. Guo, and X. Yao, "Surface and orientation effects on stress-induced hcp-fcc phase transformation in Ti nanopillars," Applied Surface Science, vol. 509, p. 145234, 2020. DOI: https://doi.org/10.1016/j.apsusc.2019.145234

Z. Wang, F. Di-Franco, A. Seyeux, S. Zanna, V. Maurice, and P. Marcus, "Passivation-induced physicochemical alterations of the native surface oxide film on 316L austenitic stainless steel," Journal of The Electrochemical Society, vol. 166, no. 11, pp. C3376-C3388, 2019. DOI: https://doi.org/10.1149/2.0321911jes

S. He, D. Jiang, and Z. Sun, "Effect of deformation-induced martensite on protective performance of passive film on 304 stainless steel," International Journal of Electrochemical Science, vol. 13, no. 5, pp. 4700-4719, 2018. DOI: https://doi.org/10.20964/2018.05.11

H. Bueno, "The critical surface tension of 316L stainless steel," M.S. Thesis, San Jose State University, 2005.

B. Uzer, "Modulating the surface properties of metallic implants and the response of breast cancer cells by surface relief induced via bulk plastic deformation," Frontiers in Materials, vol. 7, p. 99, 2020. DOI: https://doi.org/10.3389/fmats.2020.00099

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

การอนุญาต

ลิขสิทธิ์ (c) 2024 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.