The influence of aluminium dross residue and coal fly ash on the properties of geopolymers

DOI:

https://doi.org/10.55713/jmmm.v35i2.2180คำสำคัญ:

Geopolymer, aluminium dross residue, Coal fly ashบทคัดย่อ

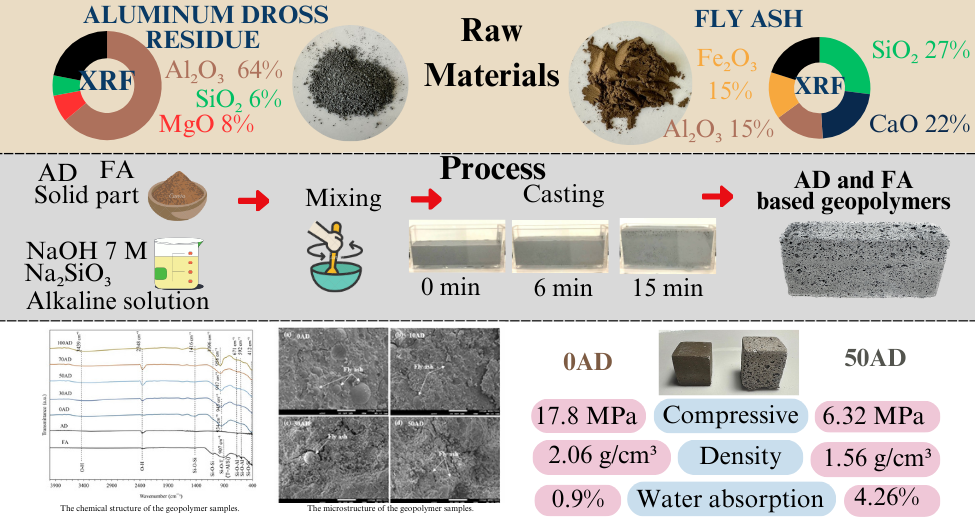

In this research, aluminium dross residue (AD) and coal fly ash (FA) were used for the production of geopolymers. The illegal dumping of AD and the high cost for AD waste disposal have been problems for long time in Thailand. Therefore, the feasibility of using AD (0 wt% to 100 wt%) in the geopolymer production had been carried out to find the alternative way to resolve these problems. The alkaline solution of NaOH 7 M and Na2SiO3 with the ratio of 1:3 was used for the geopolymerization reaction. It was found that the addition of AD caused the ammonia gas during the process, which resulted in high porosity of the samples. The low compressive strength, low density and low thermal conductivity were observed in the samples with higher AD contents. The results indicated that the sample with 50 wt% AD and 50 wt% FA gave the reasonable properties for lightweight concrete block with the density of 1.56 g∙cm‒3, the compressive strength of 6.32 MPa, and the water absorption of 4.26%. In addition, the phase structure, microstructure and the structure change of the geopolymer samples were investigated using XRD, SEM and FTIR techniques, respectively.

Downloads

เอกสารอ้างอิง

W. Poonyakanok, "Green concrete," RISC.com. https://risc.in.th/ th/knowledge/ (accessed Jan. 15, 2024)

V. Shobeiri, B. Bennett, T. Xie, and P. Visintin, "A comprehensive assessment of the global warming potential of geopolymer concrete," Journal of Cleaner Production, vol. 297, p. 126669, 2021. DOI: https://doi.org/10.1016/j.jclepro.2021.126669

F. N. Stafford, A. C. Dias, L. Arroja, J. A. Labrincha, and D. Hotza, "Life cycle assessment of the production of Portland cement: A Southern Europe case study," Journal of Cleaner Production, vol. 126, pp. 159-165, 2016. DOI: https://doi.org/10.1016/j.jclepro.2016.02.110

B. C. McLellan, R. P. Williams, J. Lay, A. van Riessen, and G. D. Corder, "Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement," Journal of Cleaner Production, vol. 19, no. 9, pp. 1080-1090, 2011. DOI: https://doi.org/10.1016/j.jclepro.2011.02.010

H. Xu, and J. S. J. Van Deventer, "The geopolymerisation of alumino-silicate minerals," International Journal of Mineral Processing, vol. 59, no. 3, pp. 247-266, 2000. DOI: https://doi.org/10.1016/S0301-7516(99)00074-5

A. M. Rashad, "A comprehensive overview about the influence of different additives on the properties of alkali-activated slag – A guide for Civil Engineer," Construction and Building Materials, vol. 47, pp. 29-55, 2013. DOI: https://doi.org/10.1016/j.conbuildmat.2013.04.011

N. Toobpeng, P. Thavorniti, and S. Jiemsirilers, "Effect of additives on the setting time and compressive strength of activated high-calcium fly ash-based geopolymers," Construction and Building Materials, vol. 417, p. 135035, 2024. DOI: https://doi.org/10.1016/j.conbuildmat.2024.135035

L. Zhang, Z. Chen, R. Chen, S. Zhu, J. Lin, and P. Tai, "Compressive strength of fly ash based geopolymer utilizing waste completely decomposed granite," Case Studies in Construction Materials, vol. 19, 2023, Art. no. e02667. DOI: https://doi.org/10.1016/j.cscm.2023.e02667

M. Ashfaq, M. Sharif, M. Irfan-ul-Hassan, U. Sahar, U. Akmal, and A. Mohamed, "Up-scaling of fly ash-based geopolymer concrete to investigate the binary effect of locally available metakaolin with fly ash," Heliyon, vol. 10, 2024, Art. no. e26331. DOI: https://doi.org/10.1016/j.heliyon.2024.e26331

M. H. Elseknidy, A. Salmiaton, I. Nor Shafizah, and A. H. Saad, "A study on mechanical properties of concrete incorporating aluminum dross, fly ash, and quarry dust," Sustainability, vol. 12, no. 21, 2020. DOI: https://doi.org/10.3390/su12219230

T. F. Choo, M. A. Mohd Salleh, K. Y. Kok, K. A. Matori, and S. Abdul Rashid, "Characterization of high-temperature hierarchical porous mullite washcoat synthesized using aluminum dross and coal fly ash," Crystals, vol. 10, no. 3, 2020. DOI: https://doi.org/10.3390/cryst10030178

P. Puksisuwan, P. Laoratanakul, and B. Cherdhirunkorn, "Utilization of aluminium dross as a main raw material for synthesis of geopolymer," Journal of Metals, Materials and Minerals, vol. 27, no. 2, 2018.

I. A Aziz, M. M. A. B. Abdullah, H. Yong, and L. Ming, "Behaviour changes of ground granulated blast furnace slag geopolymers at high temperature," Advances in Cement Research, vol. 32, pp. 1-28, 2019. DOI: https://doi.org/10.1680/jadcr.18.00162

C. S. Thunuguntla, and T. D. Gunneswara Rao, "Effect of mix design parameters on mechanical and durability properties of alkali activated slag concrete," Construction and Building Materials, vol. 193, pp. 173-188, 2018. DOI: https://doi.org/10.1016/j.conbuildmat.2018.10.189

Industrial Scientific, "Understanding ammonia (NH3) gas: risks, detection, and safety measures," https://www.indsci.com/ en/blog/understanding-ammonia-nh3-gas-risks-detection safety-measures?form=MG0AV3 (accessed Mar 1, 2025)

C. Freidin, "Cementless pressed blocks from waste products of coal-firing power station," Construction and Building Materials, vol. 21, no. 1, pp. 12-18, 2007. DOI: https://doi.org/10.1016/j.conbuildmat.2005.08.002

M. J. Mwiti, T. o. J. Karanja, and W. J. Muthengia, "Properties of activated blended cement containing high content of calcined clay," Heliyon, vol. 4, no. 8, 2018, Art. no. e00742. DOI: https://doi.org/10.1016/j.heliyon.2018.e00742

S. Lv, H. Ni, X. Wang, W. Ni, and W. Wu, "Effects of hydrolysis parameters on AlN content in aluminum dross and multi-variate nonlinear regression analysis," Coatings, vol. 12, no. 5, 2022. DOI: https://doi.org/10.3390/coatings12050552

T. Mukhametkaliyev, M. H. Ali, V. Kutugin, O. Savinova, and V. Vereschagin, "Influence of mixing order on the synthesis of geopolymer concrete," Polymers, vol. 14, no. 21, 2022. DOI: https://doi.org/10.3390/polym14214777

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

การอนุญาต

ลิขสิทธิ์ (c) 2025 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.