Analyse the mechanical property optimization for FDM/3D-printed polycarbonate using Taguchi and TOPSIS techniques

DOI:

https://doi.org/10.55713/jmmm.v35i1.2196คำสำคัญ:

FDM, 3D printing, Optimization, UTS, CMSบทคัดย่อ

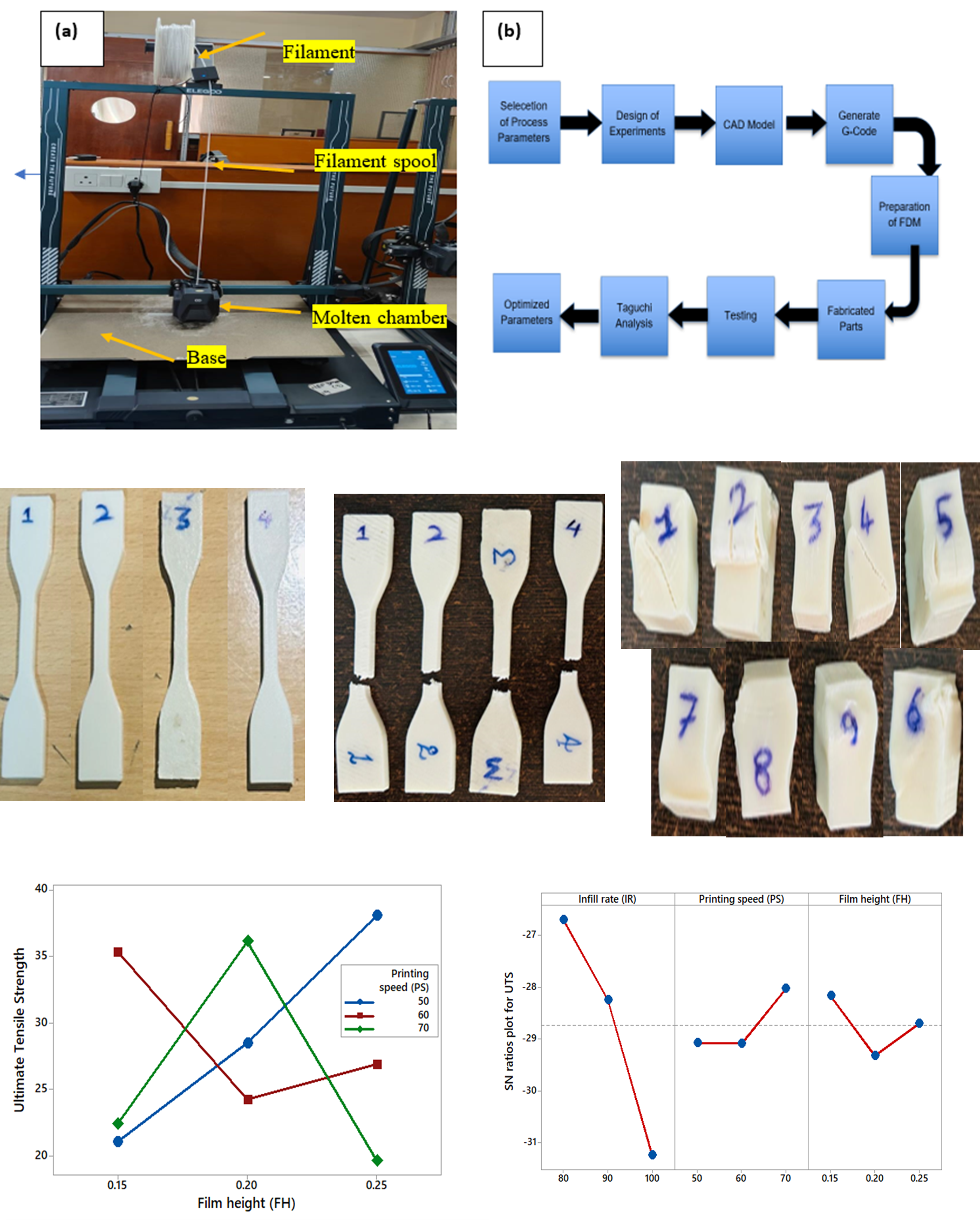

Fused Deposition Modeling is 3D printing techniques which chiefly appreciated for prototypes. This manufacturing process works by extrusion of thermoplastic materials to make the three-dimensional objects. In this work, we pursued to identify the FDM parameters to increase mechanical properties, specifically ultimate tensile strength (UTS) and compressive strength (CMS). Polycarbonate was chosen to create the test samples because of the best thermal and mechanical properties, which was the increasing manufacturing applications of 3D printing. Nine experiments were conducted to verify the interaction of the considered parameters, namely infill rate (IR), printing speed (PS), and film height (FH). The combined use of the Taguchi and TOPSIS approaches makes the interaction of the considered parameters clearer, pointing out the most favorable combinations in terms of optimizing the mechanical properties of 3D-printed polycarbonate samples. From the Taguchi-TOPSIS method results, the optimal parameters were acknowledged as IR1-PS1-FH2. An experiment focused under these optimal settings resulted in UTS of 29.59 MPa and CMS of 34.5 MPa. Furthermore, the relative closeness coefficients for the initial and optimized factors were 0.36182 and 0.7734 respectively, proving a significant improvement in product quality. Finally, this study highlighted the potential for further refinement of FDM processes in enhancing the mechanical properties, provided the valuable insights for industries leveraging additive manufacturing for high-performance applications.

Downloads

เอกสารอ้างอิง

C. Abeykoon, P. Sri-Amphorn, and A. Fernando, “Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures,” International Journal of Lightweight Materials and Manufacture, vol. 3, no. 3, pp. 284-297, 2020. DOI: https://doi.org/10.1016/j.ijlmm.2020.03.003

E. Guerra, J. de Lara, A. Malizia, and P. Díaz, “Supporting user-oriented analysis for multi-view domain-specific visual languages,” Information and Software Technology, vol. 51, no. 4, pp. 769–784, 2009. DOI: https://doi.org/10.1016/j.infsof.2008.09.005

M. Shirmohammadi, S. J. Goushchi, and P. M. Keshtiban, “Optimization of 3D printing process parameters to minimize surface roughness with hybrid artificial neural network model and particle swarm algorithm,” Progress in Additive Manufacturing, vol. 6, no. 2, pp. 199-215, 2021. DOI: https://doi.org/10.1007/s40964-021-00166-6

A. M. Chugay, and A. V. Zhuravka, “Packing optimization problems and their application in 3D printing,” Advances in Computer Science for Engineering and Education III, pp. 75-85. 2021. DOI: https://doi.org/10.1007/978-3-030-55506-1_7

T. Peng, “Analysis of energy utilization in 3D printing processes,” Procedia CIRP, vol. 40, pp. 62-67, 2016. DOI: https://doi.org/10.1016/j.procir.2016.01.055

M. Elbadawi, A. W. Basit, and S. Gaisford, “Energy consumption and carbon footprint of 3D printing in pharmaceutical manufacture,” International Journal of Pharmaceutics, vol. 639, p. 122926, 2023. DOI: https://doi.org/10.1016/j.ijpharm.2023.122926

I. Gibson, D. Rosen, and B. Stucker, Additive Manufacturing Technologies. New York, NY: Springer New York, 2015. DOI: https://doi.org/10.1007/978-1-4939-2113-3

S. Ramadan, Q. Altwarah, M. Abu-Shams, and D. Alkurdi, “Optimizing tensile strength and energy consumption for FDM through mixed-integer nonlinear multi-objective optimization and design of experiments,” Heliyon, vol. 10, no. 9, p. e30164, 2024. DOI: https://doi.org/10.1016/j.heliyon.2024.e30164

J. Gohil, R. Gohil, R. Gundaraniya, M. Prajapati, and S. Fefar, “Design and fabrication of DLP 3D printer,” Engineering, Materials Science, pp. 283-292, 2020. DOI: https://doi.org/10.1007/978-981-15-2696-1_27

L. Antonara, P. P. Dallas, and D. M. Rekkas, “A novel 3D printing enabled method for fast and reliable construction of polymeric microneedles using experimental design,” Journal of Drug Delivery Science and Technology, vol. 68, p. 102888, 2022. DOI: https://doi.org/10.1016/j.jddst.2021.102888

M. S. Kumar, M. U. Farooq, N. S. Ross, C.-H. Yang, V. Kavimani, and A. A. Adediran, “Achieving effective interlayer bonding of PLA parts during the material extrusion process with enhanced mechanical properties,” Scientific Reports, vol. 13, no. 1, p. 6800, 2023. DOI: https://doi.org/10.1038/s41598-023-33510-7

U. K. uz Zaman, E. Boesch, A. Siadat, M. Rivette, and A. A. Baqai, “Impact of fused deposition modeling (FDM) process parameters on strength of built parts using Taguchi’s design of experiments,” International Journal of Advanced Manufacturing Technology, vol. 101, no. 5-8, pp. 1215-1226, 2019. DOI: https://doi.org/10.1007/s00170-018-3014-6

H. Alzyod, L. Borbas, and P. Ficzere, “Rapid prediction and optimization of the impact of printing parameters on the residual stress of FDM-ABS parts using L27 orthogonal array design and FEA,” Materials Today: Proceedings, vol. 93, pp. 583-588, 2023. DOI: https://doi.org/10.1016/j.matpr.2023.02.213

H. Rahman, T. D. John, M. Sivadasan, and N. K. Singh, “Investigation on the scale factor applicable to ABS based FDM additive manufacturing,” Materials Today: Proceedings, vol. 5, no. 1, pp. 1640-1648, 2018. DOI: https://doi.org/10.1016/j.matpr.2017.11.258

A. Bahar, S. Belhabib, S. Guessasma, F. Benmahiddine, A. E. A. Hamami, and R. Belarbi, “Mechanical and thermal properties of 3D printed polycarbonate,” Energies, vol. 15, no. 10, p. 3686, 2022. DOI: https://doi.org/10.3390/en15103686

N. Vidakis, M. Petousis, E. velidakis, M. spiridaki, and J. D. kechagias, “mechanical performance of fused filament fabricated and 3D-printed polycarbonate polymer and polycarbonate/ cellulose nanofiber nanocomposites,” Fibers, vol. 9, no. 11, p. 74, 2021. DOI: https://doi.org/10.3390/fib9110074

X. Chen, Y. Wang, M. Liu, S. Qu, Q. Zhang, and S. Chen, “Preparation and process parameter optimization of continuous carbon fiber-reinforced polycarbonate prepreg filament,” Polymers (Basel), vol. 15, no. 3, p. 607, 2023. DOI: https://doi.org/10.3390/polym15030607

G. Gómez-Gras, M. D. Abad, and M. A. Pérez, “Mechanical performance of 3D-printed biocompatible polycarbonate for biomechanical applications,” Polymers (Basel), vol. 13, no. 21, p. 3669, 2021. DOI: https://doi.org/10.3390/polym13213669

B. Srinivas, P. Satishkumar, R. Saminathan, and B. Srikanth, “Optimization of process parameters in 3D printing of poly-carbonate for high heat applications,” Interactions, vol. 245, no. 1, p. 119, 2024. DOI: https://doi.org/10.1007/s10751-024-01961-7

B. Uhrich, M. Schäfer, O. Theile, and E. Rahm, “Using physics-informed machine learning to optimize 3D printing processes,” Progress in Digital and Physical Manufacturing, pp. 206-221, 2023. DOI: https://doi.org/10.1007/978-3-031-33890-8_18

B. Ramos, D. Pinho, D. Martins, A. I. F. Vaz, and L. N. Vicente, “Optimal 3D printing of complex objects in a 5–axis printer,” Optimization and Engineering, vol. 23, no. 5, pp. 1085-1116, 2022. DOI: https://doi.org/10.1007/s11081-021-09624-0

P. Awasthi, A. Kumar, P. M. Pandey, and S. S. Banerjee, “Optimization of process parameters of 3D printed thermoplastic elastomeric materials using statistical modeling with particular reference to mechanical properties and print quality,” Functional Composite Materials, vol. 5, no. 1, p. 6, 2024. DOI: https://doi.org/10.1186/s42252-024-00055-5

D. K. Pratiwi, A. Arifin, Gunawan, A. Mardhi, and Afriansyah, “Investigation of welding parameters of dissimilar weld of SS316 and ASTM A36 joint using a grey-based taguchi optimization approach,” Journal of Manufacturing and Materials Processing, vol. 7, no. 1, p. 39, 2023. DOI: https://doi.org/10.3390/jmmp7010039

T. T. Nguyen, V. H. Hoang, V.-T. Nguyen, and V. T. T. Nguyen, “Dissimilar MIG welding optimization of C20 and SUS201 by taguchi method,” Journal of Manufacturing and Materials Processing, vol. 8, no. 5, p. 219, 2024. DOI: https://doi.org/10.3390/jmmp8050219

S. Ahmed, R. A. ur Rahman, A. Awan, S. Ahmad, W. Akram, M. Amjad, M. Y. Yahya, and S. S. R. Koloor, “Optimization of process parameters in friction stir welding of aluminum 5451 in marine applications,” Journal of Marine Science and Engineering, vol. 10, no. 10, p. 1539, 2022. DOI: https://doi.org/10.3390/jmse10101539

K. Doungkeaw, P. Suttipong, P. Kungwankrai, S. Muengto, B. Thavornyutikarn, and J. Tungtrongpairoj, “Recycling of iron oxide waste by carbothermic reduction to utilize in FDM 3D printing materials,” Journal of Metals, Materials and Minerals, vol. 33, no. 2, pp. 156-161, 29, 2023. DOI: https://doi.org/10.55713/jmmm.v33i2.1584

A. Khosravi, M. Randjbar, And R. Habibpour, “Synthesis, characterization, and application of ZIF-8 for removal of Cd, Ni, and Pb ions from aqueous solutions: Optimization of the process by Response Surface Methodology (RSM) based on Central Composite Design (CCD) technique,” Journal of Metals, Materials and Minerals, vol. 33, no. 2, pp. 88-102, 2023. DOI: https://doi.org/10.55713/jmmm.v33i2.1668

P. Seensattayawong, C. Suwanpreecha, N. Boonlert, S. Songkuea, and A. Manonukul, “The effect of printing parameters on the properties of 17-4 PH stainless steel fabricated by material extrusion additive manufacturing,” Journal of Metals, Materials and Minerals, vol. 34, no. 2, p. 1804, 2024. DOI: https://doi.org/10.55713/jmmm.v34i2.1804

S. Vijayakumar, J. J. Kakkassery, J. Maniraj, P. S. Satheesh Kumar, M. Vignesh, and G. Anbuchezhiyan, “ANN modeling and optimization of friction stir welding performance for AA6061 and AA5083 alloy joints,” Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2024.

B. Venkatesh, R. Sivakumar, S. Vijayakumar, P. S. S. Kumar, M. N. S. Sri, and A. Pradeep, “Predict the modelling of cement concrete strength using Taguchi and ANOVA method,” Interactions, vol. 245, no. 1, 2024. DOI: https://doi.org/10.1007/s10751-024-02133-3

P. S. Kumar, V. Rao, K. P. Indira, D. J. Rani, S. Vijayakumar, and R. Haranath, “Enhancement of TIG welding performance on carbon steel by Taguchi-TOPSIS optimization,” Interactions,

vol. 245, no. 1, pp. 1-11, 2024. DOI: https://doi.org/10.55194/GI.2024.1-2.13

S. Jeyakrishnan, S. Vijayakumar, M. N. S. Sri, and P. Anusha, “An integration of RSM and ANN modelling approach for prediction of FSW joint properties in AA7178/AA5456 alloys,” Canadian Metallurgical Quarterly, pp. 1-18, 2024. DOI: https://doi.org/10.1080/00084433.2024.2310344

B. Gugulothu, K. Bharadwaja, S. Vijayakumar, T. V. J. Rao, M. N. S. Sri, P. Anusha, and M. K. Agrawal, “Modeling and parametric optimization of electrical discharge machining on casted composite using central composite design,” International Journal on Interractive Design and Manufacturing, vol. 18, pp. 2793-2803, 2024. DOI: https://doi.org/10.1007/s12008-023-01323-7

P. Anusha, M. N. S. Sri, S. Vijayakumar, T. V. J. Rao, P. Paramasivam, S. Jeyakrishnan, and K. K. Saxena, “Design and optimization the wear characteristics for Al7178/TiO2/B4C/FA central hybrid composite,” International Journal on Interactive Design and Manufacturing, vol. 18, no. 8, pp. 5773-5781, 2023. DOI: https://doi.org/10.1007/s12008-023-01341-5

S. Karumuri, B. Haldar, A. Pradeep, S. A. K. Karanam, M. N. S. Sri, A. Peyyala, N. Sateesh, R. Subbian, and S. Vijayakumar, “Multi-objective optimization using Taguchi based grey relational analysis in friction stir welding for dissimilar aluminium alloy,” International Journal on Interactive Design and Manufacturing, vol. 18, no. 3, pp. 1-18, 2023. DOI: https://doi.org/10.1007/s12008-023-01529-9

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

Categories

การอนุญาต

ลิขสิทธิ์ (c) 2025 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.