Effects of welding currents on microstructure and corrosion behaviors of Inconel 625 cladding on 2.25Cr-1Mo steel by Hot-wire TIG

DOI:

https://doi.org/10.55713/jmmm.v36i1.2422คำสำคัญ:

2.25Cr-1Mo steel, Inconel 625, Hot-wire TIG, Cladding, Corrosion behaviorsบทคัดย่อ

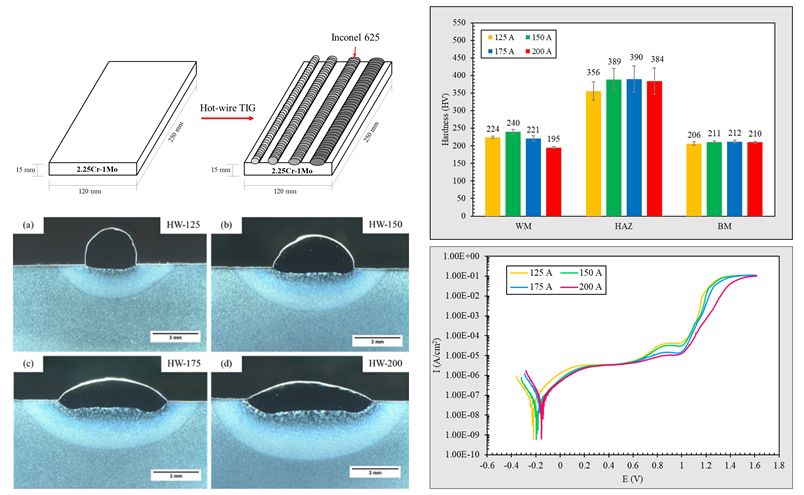

Hot-wire tungsten inert gas (HW-TIG) cladding has been applied to the steam turbine rotor welding repair. This study investigated the effects of welding currents on microstructure, hardness, and corrosion behavior. The experiments were conducted using four different welding currents applied to bead-on-plate Inconel 625 welds on a 2.25Cr-1Mo steel substrate as the steam turbine rotor material. The selected welding currents were 125 A, 150 A, 175 A, and 200 A. The percentages of weld dilution for different welding currents were also evaluated. Higher welding currents increased weld dilution, weld bead width, and HAZ size. As the welding current increased, the nickel alloy weld metal became more diluted with the base metal. The microstructure of the weld metal was a dendritic austenite phase. The weld metal exhibited the highest hardness at 150 A, with an average of 240 HV0.2. And the lowest hardness at 200 A, with an average of 195 HV0.2. The electrochemical corrosion test performed in a 3.5% NaCl solution showed that the corrosion rate was lowest in the weld metal at 150 A. According to the analytical results, a welding current of 150 A was found to be the most suitable for repairing steam turbine rotors using the HW-TIG process.

Downloads

เอกสารอ้างอิง

J. Kuželka, M. Nesládek, M. Lutovinov, J. Jurenka, M. Růžička, M. Rund, and P. Měšťánek, “Numerical simulations of fatigue crack growth in a steam turbine rotor blade groove,” Procedia Structural Integrity, vol. 17, pp. 780-787, 2019.

M. Nesládek, M. Bartošák, J. Jurenka, J. Papuga, M. Růžička, P. Měšt’ánek, and J. Džugan, "Thermo-mechanical fatigue prediction of a steam turbine shaft," MATEC Web of Conferences, vol. 165, p. 22016, 2018.

Z. Mazur, and A. Hernandez-Rossette, “Steam turbine rotor discs failure evaluation and repair process implementation,” Engineering Failure Analysis, vol. 56, pp. 545-554, 2015.

S. Barella, M. Bellogini, M. Boniardi, and S. Cincera, “Failure analysis of a steam turbine rotor,” Engineering Failure Analysis, vol. 18, no. 6, pp. 1511-1519, 2011.

J. Chen, and D. Jiang, "Dynamic response of steam seal rubbing in steam turbine considering thermal effect," Prognostics and System Health Management Conference (PHM-Harbin), pp. 1-6, 2017.

M. Wu, Y. Zhao, and F. Meng, "The analysis and solution of contact rubbing fault for low pressure rotor of gas-steam combined cycle turbine unit." IOP Conference Series: Earth and Environmental Science, vol. 446, no. 2, p. 022078, 2020.

C. Liu, D. Jiang, J. Chen, and J. Chen, “Torsional vibration and fatigue evaluation in repairing the worn shafting of the steam turbine,” Engineering Failure Analysis, vol. 26, pp. 1-11, 2012.

F. Tancsics, N. Légmán, L. Varga, and H. Hargitai, “Advantages of corrosion-resistant overlay welding on steel S355J2N,” Applied Sciences, vol. 15, no. 7, pp. 3832, 2025.

Y. Huang, M.-Y. Song, F.-Z. Xuan, and S. Weng, “Effect of overlaying welding repair on stress corrosion cracking sensitivity of low-pressure nuclear steam turbine rotor in the simulated environment,” Journal of Materials Engineering and Performance, vol. 32, no. 5, pp. 2205-2217, 2023.

N. Pravin Kumar, G. Sreedhar, S. Mohan Kumar, B. Girinath, A. Rajesh Kannan, R. Pramod, N. Siva Shanmugam, and M. Vishnukumar, “Microstructure and electrochemical evaluation of ER-308L weld overlays on AISI 321 stainless steel for repair applications,” Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, vol. 238, no. 1, pp. 441-450, 2024.

C. Borgmann, P. Dumstorff, T.-U. Kern, H. Almstedt, and K. Niepold, “Integrated weld quality concept—A holistic design

approach for steam turbine rotor weld joints,” Journal of Engineering for Gas Turbines and Power, vol. 138, no. 4, pp. 042601, 2016.

R. Donnini, A. Varone, A. Palombi, S. Spiller, P. Ferro, and G. Angella, “High energy density welding of ni-based superalloys: An overview,” Metals (2075-4701), vol. 15, no. 1, 2025.

R. G. N. Silva, A. d. S. P. Pereira, J. M. S. de Sousa, and M. Pereira, “Tribological comparison of Inconel 625 coatings deposited via laser metal deposition and tungsten inert gas welding process,” Journal of Laser Applications, vol. 32, no. 2, 2020.

E. Spaniol, T. Ungethüm, M. Trautmann, K. Andrusch, M. Hertel, and U. Füssel, “Development of a novel TIG hot-wire process for wire and arc additive manufacturing,” Welding in the World, vol. 64, pp. 1329-1340, 2020.

J. Bai, C. Fan, S. b. Lin, C. Yang, and B. Dong, “Effects of thermal cycles on microstructure evolution of 2219-Al during GTA-additive manufacturing,” The International Journal of Advanced Manufacturing Technology, vol. 87, pp. 2615-2623, 2016.

K. Shinozaki, M. Yamamoto, K. Mitsuhata, T. Nagashima, T. Kanazawa, and H. Arashin, “Bead formation and wire temperature distribution during ultra-high-speed GTA welding using pulse-heated hot-wire,” Welding in the World, vol. 55, pp. 12-18, 2011.

H. Wang, S. Hu, Z. Wang, and Q. Xu, “Arc characteristics and metal transfer modes in arcing-wire gas tungsten arc welding,” The International Journal of Advanced Manufacturing Technology, vol. 86, pp. 925-933, 2016.

R. Darji, V. Badheka, K. Mehta, J. Joshi, A. Yadav, and A. K. Chakraborty, “Investigation on stability of weld morphology, microstructure of processed zones, and weld quality assessment for hot wire gas tungsten arc welding of electrolytic tough pitch copper,” Materials and Manufacturing Processes, vol. 37, no. 8, pp. 908-920, 2022.

M. Santangelo, B. Silwal, and A. Purdy, "Vibration assisted robotic hot-wire gas tungsten arc welding (GTAW) for additive manufacturing of large metallic parts," in Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference, pp. 1548-1556. 2016,

A. Pai, I. Sogalad, S. Albert, P. Kumar, T. Mitra, and S. Basavarajappa, “Comparison of microstructure and properties of modified 9Cr-1Mo welds produced by narrow gap hot wire and cold wire gas tungsten arc welding processes,” Procedia Materials Science, vol. 5, pp. 1482-1491, 2014.

A. Pai, I. Sogalad, S. Basavarajappa, and P. Kumar, “Assessment of impact strength of welds produced by cold wire and hot wire gas tungsten arc welding (GTAW) processes,” Materials Today: Proceedings, vol. 24, pp. 983-994, 2020.

B. Silwal, and M. Santangelo, “Effect of vibration and hot-wire gas tungsten arc (GTA) on the geometric shape,” Journal of Materials Processing Technology, vol. 251, pp. 138-145, 2018.

P. Zhilin, G. Gavrilov, E. Gerasimov, and O. Melnichenko, “Advanced welding and cladding methods using auxiliary cold and hot wires,” Procedia Structural Integrity, vol. 30, pp. 209-215, 2020.

O. Muránsky, H. Zhu, S.-L. Lim, K. Short, J. Cairney, and M. Drew, “On the evolution of mechanical properties and micro-structure of ferritic-bainitic (FB) 2.25 Cr-1Mo (Grade 22) steel during high-temperature creep,” Materialia, vol. 9, pp. 100513, 2020.

P. Thejasree, N. Manikandan, J. Binoj, K. Varaprasad, D. Palanisamy, and R. Raju, “Numerical simulation and experimental investigation on laser beam welding of Inconel 625,” Materials today: proceedings, vol. 39, pp. 268-273, 2021.

A. Kreitcberg, K. Inaekyan, S. Turenne, and V. Brailovski, “Temperature-and time-dependent mechanical behavior of post-treated IN625 alloy processed by laser powder bed fusion,” Journal of Manufacturing and Materials Processing, vol. 3, no. 3, pp. 75, 2019.

P. Elango, and S. Balaguru, “Welding parameters for Inconel 625 overlay on carbon steel using GMAW,” Indian Journal of Science and Technology, vol. 8, no. 31, pp. 1-5, 2015.

C. P. Alvaraes, J. C. Jorge, L. F. de Souza, L. S. Araujo, M. C. Mendes, and H. N. Farneze, “Microstructure and corrosion properties of single layer Inconel 625 weld cladding obtained by the electroslag welding process,” Journal of Materials Research and Technology, vol. 9, no. 6, pp. 16146-16158, 2020.

J. S. Kim, Y. I. Park, and H. W. Lee, “Effects of heat input on the pitting resistance of Inconel 625 welds by overlay welding,” Metals and Materials International, vol. 21, pp. 350-355, 2015.

J. H. Park, M. Cheepu, and S. M. Cho, “Analysis and characterization of the weld pool and bead geometry of Inconel 625 super-TIG welds,” Metals, vol. 10, no. 3, pp. 365, 2020.

F. Cao, S. Chen, and C. Du, “Investigation of hot-wire TIG welding based on the heat-conduction,” Energy Procedia, vol. 144, pp. 9-15, 2018.

C. Fujun, Z. Jingqi, and D. Chengchao, “Hot-wire TIG welding based on the heat-conduction,” zggx, vol. 48, no. 6, pp. 104-109, 2023.

B. Silwal, J. Walker, and D. West, “Hot-wire GTAW cladding: inconel 625 on 347 stainless steel,” The International Journal of Advanced Manufacturing Technology, vol. 102, pp. 3839-3848, 2019.

A. Evangeline, and P. Sathiya, “Structure–property relationships of Inconel 625 cladding on AISI 316L substrate produced by hot wire (HW) TIG metal deposition technique,” Materials Research Express, vol. 6, no. 10, pp. 106539, 2019.

C. Magadum, S. Ponnusamy, M. Muthukrishnan, and B. Nair, “Developments and improvements using hot wire gas tungsten arc welding–A review,” Applied Science and Engineering Progress, vol. 16, no. 2, pp. 5965-5965, 2023.

A. Fande, S. Kavishwar, V. Tandon, D. C. Narayane, and D. Bandhu, “Influence of inconel interlayer on microstructural, mechanical and electrochemical characteristics in single-pass ATIG welding of dissimilar austenitic and duplex stainless steel,” Materials Research Express, vol. 11, no. 5, pp. 056519, 2024.

A. Kumar, S. M. Pandey, and C. Pandey, "Dissimilar weldments of ferritic/martensitic grade P92 steel and Inconel 617 alloy: Role of groove geometry on mechanical properties and residual stresses," Archives of Civil and Mechanical Engineering, vol. 23, no. 1, p. 54, 2022.

X. Xu, G. Mi, L. Chen, L. Xiong, P. Jiang, X. Shao, and C. Wang, “Research on microstructures and properties of Inconel 625 coatings obtained by laser cladding with wire,” Journal of alloys and Compounds, vol. 715, pp. 362-373, 2017.

K. Song, Z. Wang, S. Hu, S. Zhang, and E. Liang, "Welding current influences on Inconel 625/X65 cladding interface," Materials and Manufacturing Processes, vol. 33, no. 7, pp. 770-777, 2018.

Y. Liu, X. Xue, H. Fang, Y. Tan, H. Cui, and R. Chen, "Columnar grains formation and mechanical properties improvement of Ti44Al alloy by cyclic directional heat treatment," Journal of Materials Research And Technology, vol. 9, no. 6, pp. 16355-16366, 2020.

C. C. Silva, H. C. De Miranda, M. F. Motta, J. P. Farias, C. R. M. Afonso, and A. J. Ramirez, "New insight on the solidification path of an alloy 625 weld overlay," Journal of Materials research and Technology, vol. 2, no. 3, pp. 228-237, 2013.

W. Li, W. Liu, H. Liu, Z. Ma, T. Wang, G. Hu, Z. Lyu, H. Zhang, J. Song, and B. Liu, “Research and prospect on microstructure and properties of laser additive manufactured parts,” The International Journal of Advanced Manufacturing Technology, vol. 130, no. 5, pp. 2023-2064, 2024.

L. Guo, F. Xiao, F. Wang, W. Wei, Y. He, and F. Luo, “Influence of heat treatments on microstructure, mechanical properties and corrosion resistance of Inconel 625 overlay cladded using PTIG,” Materials Research Express, vol. 7, no. 9, pp. 096517, 2020.

C. Zhang, Z. Qiu, H. Zhu, Z. Wang, O. Muránsky, M. Ionescu, Z. Pan, J. Xi, and H. Li, “On the effect of heat input and interpass temperature on the performance of inconel 625 alloy deposited using wire arc additive manufacturing–cold metal transfer process,” Metals, vol. 12, no. 1, pp. 46, 2021.

X. You, Y. Tan, L. Zhao, Q. You, Y. Wang, F. Ye, and J. Li, “Effect of solution heat treatment on microstructure and electro-chemical behavior of electron beam smelted Inconel 718 superalloy,” Journal of Alloys and Compounds, vol. 741, pp. 792-803, 2018.

L. Tsay, C. Liu, Y.-H. Chao, and Y. Shieh, “Fatigue crack propagation in 2.25 Cr–1.0 Mo steel weldments in air and hydrogen,” Materials Science and Engineering: A, vol. 299, no. 1-2, pp. 16-26, 2001.

G. d. S. Vacchi, R. Silva, C. L. Kugelmeier, C. B. M. Junior, I. Dainezi, J. H. Alano, A. d. A. Mendes Filho, W. R. Ramos Osorio, and C. A. Della Rovere, “Corrosion behavior of CW6MC nickel cast alloy (Inconel 625) welded by shielded metal arc welding,” Metals, vol. 11, no. 8, pp. 1286, 2021.

K. Łyczkowska, and J. Michalska, “Studies on the corrosion resistance of laser-welded Inconel 600 and Inconel 625 nickel-based superalloys,” Archives of Metallurgy and Materials, vol. 62, 2017.

F. Ostovan, E. Hasanzadeh, M. Toozandehjani, E. Shafiei, K. R. Jamaluddin, and A. Amrin, “Microstructure, hardness and corrosion behavior of gas tungsten arc welding clad Inconel 625 super alloy over A517 carbon steel using ERNiCrMo3 filler metal,” Journal of Materials Engineering and Performance, vol. 29, pp. 6919-6930, 2020.

J.-S. Kim, and H.-W. Lee, “A study on effect of intergranular corrosion by heat input on Inconel 625 overlay weld metal,” International Journal of Electrochemical Science, vol. 10, no. 8, pp. 6454-6464, 2015.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

Categories

การอนุญาต

ลิขสิทธิ์ (c) 2025 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.