Utilization of silicon dioxide powder from industrial wastes as novel filler in rubber isolator application

DOI:

https://doi.org/10.55713/jmmm.v32i1.1205Keywords:

Natural rubber, Silicon dioxide, Calcium carbonate, Industrial wastes, Damping propertyAbstract

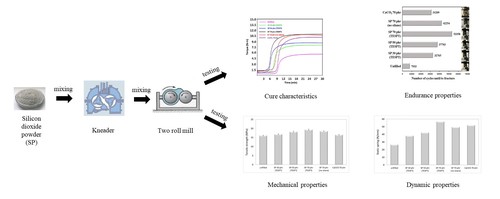

The silicon dioxide powder (SP) was an industrial waste and obtained from the silicon metal industry in Thailand. The effect of SP loading on cure characteristics, mechanical, dynamic and endurance properties in natural rubber were investigated and compared to calcium carbonate (CaCO3) and unfilled natural rubber, respectively. Results revealed that the addition of SP significantly affected the cure characteristics and mechanical properties. An increasing content of SP increased the hardness, modulus, tensile strength and tear strength due to a higher SP-rubber interaction but decreased the elongation at break since higher SP in rubber matrix resulting in lesser mobility of rubber chains. For the curing behavior, the faster cure time was observed since more heat transfer to the compound occurred. The rubber product performance in terms of dynamic and endurance properties of rubber isolator were also determined. It had been found that SP not only improving the damping characteristics but also enhancing the number of cycles until fracture. Moreover, adding the bis-(3-triethoxysilylpropyl)-tetrasulphide (TESPT) showed higher reinforcement efficiency of SP. This can directly react to silanol groups on the SP surface and also reduce hydrogen bonding of SP particles. So, TESPT can reduce accelerator adsorption and SP-SP interaction, leading to better processability. Besides that, TESPT is a sulphur-based rubber silane. It can contribute sulphur atoms from molecule and then form covalent bonds with natural rubber chains which leads to enhance the crosslink density. Influence of filler type on rubber isolator, the SP imparts greater reinforcement than CaCO3. All obtained results suggested that SP can be fully replaced the commercial CaCO3.

Downloads

References

T. Spratte, J. Plagge, M. Wunde, and M. Klüppel, "Investigation of strain-induced crystallization of carbon black and silica filled natural rubber composites based on mechanical and temperature measurements," Polymer, vol. 115, pp. 12-20, 2017.

S. Qian, J. Huang, W. Guo, and C. Wu, "Investigation of carbon black network in natural rubber with different bound rubber contents," Journal of Macromolecular Science, Part B, vol. 46, pp. 453-466, 2007.

V. R. Vijay, A. M. Anitha, and A. R. R. Menon, "Studies on blends of natural rubber and butadiene rubber containing silica - Organomodified kaolin hybrid filler systems," Polymer, vol. 89, pp. 135-142, 2016.

J. Zheng, D. Han, X. Ye, X. Wu, Y. Wu, Y. Wang, and L. Zhang, "Chemical and physical interaction between silane coupling agent with long arms and silica and its effect on silica/natural rubber composites," Polymer, vol. 135, pp. 200-210, 2018.

J. H. Ma, L. Q. Zhang, and Y. P. Wu, "Characterization of filler-rubber interaction, filler network structure and their effects on viscoelasticity for styrene-butadiene rubber filled with different fillers," Journal of Macromolecular Science, Part B, vol. 52, pp. 1128-1141, 2013.

C. Yin, Q. Zhang, J. Gu, Z. Zhao, J. Zheng, G. Gong, T. Liang, and H. Zhang, "Cure characteristics and mechanical properties of vinyltriethoxysilane grafted styrene-butadiene rubber/silica blends," Polymer-Plastics Technology and Engineering, vol. 51, pp. 1218-1222, 2012.

K. Kim, B. Seo, J. Y. Lee, B. J. Choi, G. H. Kwag, H. J. Paik, and W. Kim, "Reduced filler flocculation in the silica-filled styrene-butadiene-glycidyl methacrylate terpolymer," Composite Interface, vol. 22, pp. 137-149, 2015.

D. Moonchai, N. Moryadee, and N. Poosodsang, "Comparative properties of natural rubber vulcanisates filled with defatted rice bran, clay and calcium carbonate," Maejo International Journal of Science and Technology, vol. 6, pp. 249-258, 2012.

G. C. Basak, A. Bandyopadhyay, and A. Bhowmick, "Influence of nanoclay on adhesion of EPDM vulcanizate," International Journal of Adhesion and Adhesives, vol. 31, pp. 209-219, 2011.

H. Ismail, and M. Mathialagan, "Comparative study on the effect of partial replacement of silica or calcium carbonate by bentonite on the properties of EPDM composites," Polymer Testing, vol. 31, pp. 199-208, 2012.

Q. Wang, Q. Song, J. Qiao, X. Zhang, L. Zhang, and Z. Song, "Good dispersion of hydrophilic nanoscale calcium carbonate particles in nitrile butadiene rubber matrix," Polymer, vol. 52, pp. 3496-3502, 2011.

Q. Fang, B. Song, T. T. Tee, L. T. Sin, D. Hui, and S. T. Bee, "Investigation of dynamic characteristics of nano-size calcium carbonate added in natural rubber vulcanizate," Composites Part B, vol. 60, pp. 561-567, 2014.

S. Moonchai, and D. Moonchai, "Modelling and optimization of rebound resilience and hardness of defatted rice bran/calcium carbonate-filled NR vulcanisates," Polymer Testing, vol. 32, pp. 1472-1478, 2013.

S. Attharangsan, H. Ismail, M. A. Bakar, and J. Ismail, "The effect of rice husk powder on standard malaysian natural rubber grade L (SMR L) and epoxidized natural rubber (ENR 50) composites," Polymer-Plastics Technology and Engineering, vol. 51, pp. 231-237, 2012.

K. Ahmeda, S. S. Nizami, and N. Z. Raza, "Characteristics of natural rubber hybrid composites based on marble sludge/carbon black and marble sludge/rice husk derived silica," Journal of Industrial and Engineering Chemistry, vol. 19, pp. 1169-1176, 2013.

C. S. Barrera, and K. Cornish, "Processing and mechanical properties of natural rubber/waste-derived nano filler composites compared to macro and micro filler composites," Industrial Crops and Products, vol. 107, pp. 217-231, 2017.

S. Satapathy, A. Nag, and G. B. Nando, "Thermoplastic elastomers from waste polyethylene and reclaim rubber blends and their composites with fly ash," Process Safety and Environmental Protection, vol. 88, pp. 131-141, 2010.

S. Thongsang, W. Vorakhan, E. Wimolmala, and N. Sombatsompop, "Dynamic mechanical analysis and tribiological properties of NR vulcanizates with fly ash/precipitated silica hybrid filler," Tribology International, vol. 53, pp. 134-141, 2012.

M. Labella, S. E. Zeltmann, V. C. Shunmugasamy, N. Gupta, and P. K. Rohatgi, "Mechanical and thermal properties of fly ash/vinyl ester syntactic foams," Fuel, vol. 121, pp. 240-249, 2014.

Y. Li, B. Han, L. Liu, F. Zhang, L. Zhang, S. Wen, Y. Lu, H. Yang, and J. Shen, "Surface modification of silica by two-step method and properties of solution styrene butadiene rubber (SSBR) nanocomposites filled with modified silica," Composites Science and Technology, vol. 88, pp. 69-75, 2013.

L. Chen, Z. Jia, Y. Tang, L. Wu, Y. Luo, and D. Jia, "Novel functional silica nanoparticles for rubber vulcanization and reinforcement," Composites Science and Technology, vol. 144, pp. 11-17, 2017.

L. Guy, S. Daydey, P. Cochet, and Y. Bomal, "New insights in the dynamic properties of precipitated silica filled rubber using a new high surface silica," Kautscuk, Gummi, Kunststoffe, vol. 62, pp. 383-391, 2009.

H. Ismail, R. Nordin, and A. M. Noor, "The effect of filler loading on curing and mechanical properties of natural rubber/ recycled rubber powder blends," International Journal of Polymeric Materials and Polymeric Biomaterials, vol. 54, pp. 9-20, 2005.

Y. Changjie, Q. Zhang, G. Junwei, Z. Junping, S. Youqiang, and W. Yuhang, "Cure characteristics and mechanical properties of styrene-butadiene rubber/hydrogenated acrylonitrile-butadiene rubber/silica composites," Journal of Polymer Research, vol. 18, pp. 2487-2494, 2011.

H. Zhang, Y. Gao, F. Li, Z. Zhang, Y. Liu, and G. Zhao, "Influence of silane coupling agents on vulcanised natural rubber: dynamic properties and heat buildup," Plastics, Rubber and Composites, vol. 45, pp. 9-15, 2016.

P. Sae-oui, C. Sirisinha, U. Thepsuwan, and K. Hatthapanit, " Roles of silane coupling agents on properties of silica-filled polychloroprene," European Polymer Journal, vol. 42, pp. 479-486, 2006.

S. Attharangsan, H. Ismail, M. A. Bakar, and J. Ismail, "Carbon black (CB)/rice husk powder (RHP) hybrid filler-filled natural rubber composites: Effect of CB/RHP ratio on property of the composites," Polymer-Plastics Technology and Engineering, vol. 57, pp. 655-662, 2012.

I. Surya, H. Ismail, and A. R. Azura, "The comparison of alkanolamide and silane coupling agent on the properties of silica-filled natural rubber (SMR-L) compounds, " Polymer Testing, vol. 40, pp.24-32, 2014.

S. S. Idrus, H. Ismail, and S. Palaniandy, "The effects of silanized ultrafine on the curing characteristics, tensile properties, and morphological study of natural rubber compounds," Polymer-Plastics Technology and Engineering, vol. 50, pp. 1-7, 2011.

P. Sae-oui, C. Sirisinha, U. Thepsuwan, and K. Hatthapanit, "Comparison of reinforcing efficiency between Si-69 and Si-264 in a conventional vulcanization system," Polymer Testing, vol. 23, pp. 871-879, 2004.

G. S. Shibulal, J. Y. Jang, H. C. Yu, Y. Huh, and C. Nah, "Cure characteristics and physico-mechanical properties of a conventional sulphur-cured natural rubber with a novel anti-reversion agent," Journal of Polymer Research, vol. 23, pp. 1-12, 2016.

K. Tsongas, D. Tzetzis, and G. Mansour, "Mechanical and vibration isolation behaviour of acrylonitrile-butadiene rubber/ multi-walled carbon nanotube composite machine mounts," Plastics Rubber and Composites, vol. 46, pp. 458-468, 2017.

C. S. J. Chandra, P. K. Bipinbal, and K. N. Sunil, "Viscoelastic behaviour of silica filled natural rubber composites - Correlation of shear with elongational testing," Polymer Testing, vol. 60, pp. 187-197, 2017.

M. Zurina, H. Ismail, and C. T. Ratnam, "Characterization of irradiation-induced crosslink of epoxidised natural rubber/ ethylene vinyl acetate (ENR-50/EVA) blend," Polymer Degradation and Stability, vol. 91, pp. 2723-2730, 2006.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.