Extraction, characterization, and improvement of banana stem and water hyacinth cellulose fibers as reinforcement in cementitious composites

DOI:

https://doi.org/10.55713/jmmm.v32i3.1524Keywords:

Banana stems fiber, Water hyacinth fiber, Cellulose extraction, Chemical composition, Cement-based compositesAbstract

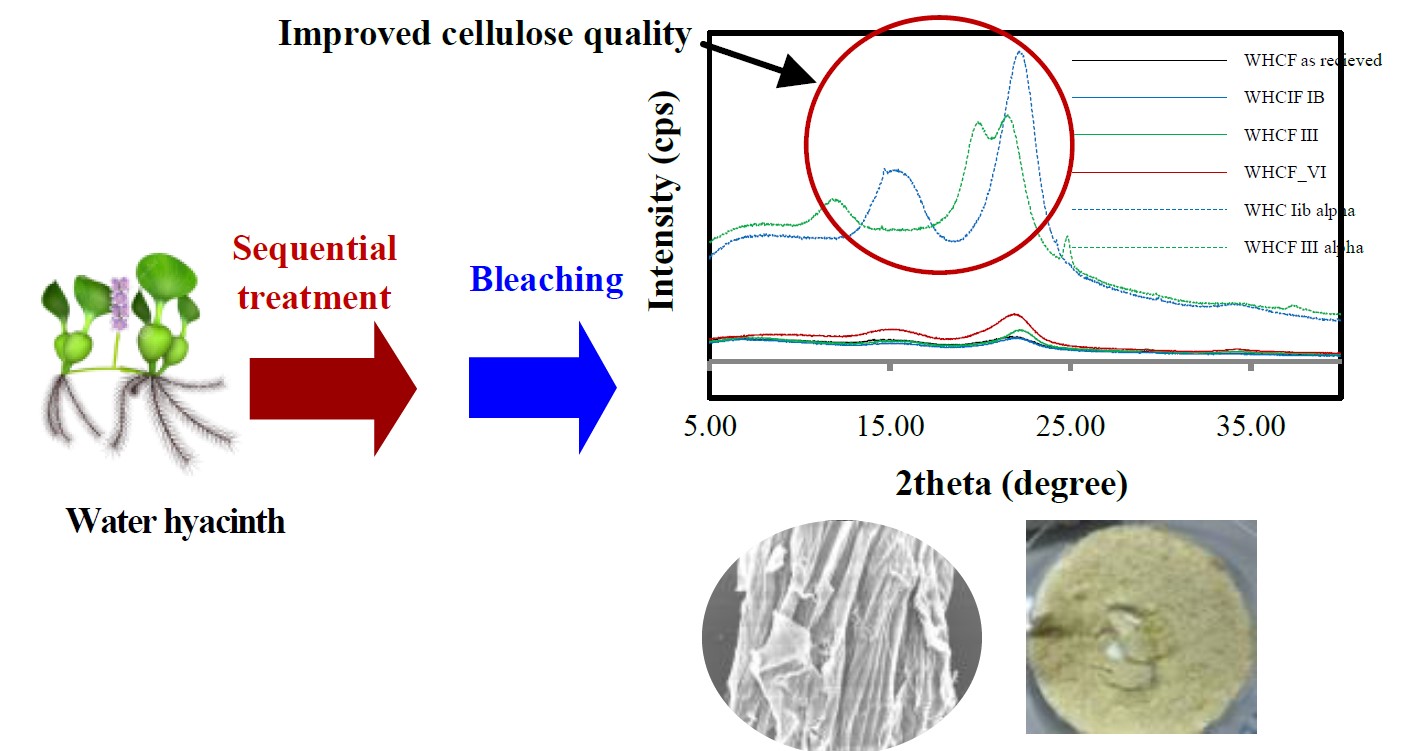

A sequential treatment for cellulose isolation from the banana stalk (BNSF) and water hyacinth (WHCF) based on the simultaneous fractionation of hemicelluloses and lignin by alkaline peroxide extraction has been studied. The crude cellulose was then purified by using an acetic acid-nitric acid mixture and further bleached with acidified sodium chlorite. The isolated cellulose was subject to analyses of associated hemicelluloses and lignin content. The structural changes between crude and purified celluloses were revealed by using FT-IR, TGA, and XRD analyses. The successive alkaline and bleaching treatments led to a significant loss in hemicelluloses and lignin, enrichment of the cellulose fraction, and increase in cellulose crystallinity but led to 3.1% to 5.4% degradation of the original cellulose. The crystallinity index of isolated cellulose was found to be increased from 38% to 90% for WHCF and 62% to 95% for BNSF. The cement composite with purified WHCF and BNSF exhibited comparable flexural strength to pure cement. The results showed that the flexural strength of the composites with 2.33 wt% of α-WHCF, 2.33 wt% of α-BNSF, and without fibers was 13.89 10.65 and 8.65 MPa, respectively. In other words, the flexural strength of the composite with α-WHCF was improved by 125%.

Downloads

References

K. A. Iyer and J. M. Torkelson, “Sustainable Green Hybrids of Polyolefins and Lignin Yield Major Improvements in Mechanical Properties When Prepared via Solid-State Shear Pulverization,” ACS Sustainable Chemistry & Engineering, vol. 3, pp. 959-968, 2015. DOI: https://doi.org/10.1021/acssuschemeng.5b00099

R. S. P. Coutts, “Wood fibre reinforced cement composites,” in Natural Fiber Reinforced Cement and Concrete, ed Glasow: Blackie and Sons Ltd, 1988, pp. 1-62.

M. A. Aziz, P. Paramasivan, and S. L. Lee, “Prospects for natural fibre reinforced concretes in construction,” International Journal of Cement Composites and Lightweight Concrete, vol. 3, pp. 123-132, 1981.

R. S. P. Coutts, “Eucalyptus wood fibre-reinforced cement,” Journal of Materials Science Letters, vol. 6, pp. 955-957, 1987. DOI: https://doi.org/10.1007/BF01729880

W. H. Zhu, B. C. Tobias, R. S. P. Coutts, and G. Langfors, “Air-cured banana-fibre-reinforced cement composites,” Cement and Concrete Composites, vol. 16, pp. 311-319, 1994. DOI: https://doi.org/10.1016/0958-9465(94)90045-0

L. K. Aggarwal, “Bagasse-reinforced cement composites,” Cement and Concrete Composites, vol. 17, pp. 107-112, 1995. DOI: https://doi.org/10.1016/0958-9465(95)00008-Z

H. J. Savastano, P. G. Warden, and R. S. P. Coutts, “Brazilian waste fibres as reinforcement for cement-based composites,” Cement and Concrete Composites, vol. 22, pp. 379-384, 2000.

H. J. Savastano, P. G. Warden, and R. S. P. Coutts, “Mechanically pulped sisal as reinforcement in cementitious matrices,” Cement and Concrete Composites, vol. 25, pp. 311-319, 2003. DOI: https://doi.org/10.1016/S0958-9465(02)00055-0

K. Bilba, M. A. Arsène, and A. Ouensanga, “Sugar cane bagasse reinforced cement composites,” Cement and Concrete Composites, vol. 25, pp. 91-96, 2003. DOI: https://doi.org/10.1016/S0958-9465(02)00003-3

H. J. Savastano, P. G. Warden, and R. S. P. Coutts, “Potential of alternative fibre cements as building materials for developing areas,” Cement and Concrete Composites, vol. 25, pp. 585-592, 2003.

R. D. Tolêdo Filho, K. Ghavami, G. L. England, and K. Scrivener, “Development of vegetable fibre-mortar composites of improved durability,” Cement and Concrete Composites, vol. 25, pp. 185-196, 2003. DOI: https://doi.org/10.1016/S0958-9465(02)00018-5

S. G. Bergström, and E.-H. Gram, “Durability of alkali-sensitive fibres in concrete,” International Journal of Cement Composites and Lightweight Concrete, vol. 6, pp. 75-80, 1984.

M. Nehdi, “Performance of rice husk ash produced using a new technology as mineral admixture in concrete,” Cement and Concrete Research, vol. 33, pp. 1203-1210. 2003. DOI: https://doi.org/10.1016/S0008-8846(03)00038-3

M. J. Carthy, and R. K. Dhir, “Development of high volume fly ash cements for use in concrete construction,” Fuel, vol. 84, pp. 1423-1432, 2005. DOI: https://doi.org/10.1016/j.fuel.2004.08.029

E. Sakai, S. Miyahara, S. Ohsawa, S.-H Lee and M. Daimon, “Hydration of fly ash cement,” Cement and Concrete Research, vol. 35, pp. 1135-1140, 2005. DOI: https://doi.org/10.1016/j.cemconres.2004.09.008

P. S. Lima Souza, and D. C. C. Dal Molin, “Viability of using calcined clays, from industrial by-products, as pozzolans of high reactivity,” Cement and Concrete Research, vol. 35, pp. 1993-1998, 2005. DOI: https://doi.org/10.1016/j.cemconres.2005.04.012

H. J. Savastano, V. Agopyan, A. M. Nolasco, and L. Pimentel, “Plant fibre reinforced cement components for roofing,” Construction and Building Materials, vol. 13, pp. 433-438, 1999. DOI: https://doi.org/10.1016/S0950-0618(99)00046-X

M. A. Aziz, P. Paramasivan, and S. L. Lee, “Prospects for natural fibre reinforced concretes in construction,” International Journal of Cement Composites and Lightweight Concrete, vol. 3, pp. 123–132, 1981. DOI: https://doi.org/10.1016/0262-5075(81)90006-3

R. Rocha Almeida, C. Henrique Soares Del Menezzi and D. Eterno Teixeira, “Utilization of the coconut shell of babaçu (Orbignya sp.) to produce cement-bonded particleboard,” Bioresource Technology, vol. 85, pp. 159-163, 2002. DOI: https://doi.org/10.1016/S0960-8524(02)00082-2

N. J. Rodríguez, M. Yáñez-Limón, F. A. Gutiérrez-Miceli, O. Gomez-Guzman, T. P. Matadamas-Ortiz, L. Lagunez-Rivera, and J. A. Feijoo, “Assessment of coconut fibre insulation characteristics and its use to modulate temperatures in concrete slabs with the aid of a finite element methodology,” Energy and Buildings, vol. 43, pp. 1264-1272, 2011. DOI: https://doi.org/10.1016/j.enbuild.2011.01.005

K. Gunasekaran, P. S. Kumar, and M. Lakshmipathy, “Mechanical and bond properties of coconut shell concrete,” Construction and Building Material, vol. 25, pp. 92-98, 2011. DOI: https://doi.org/10.1016/j.conbuildmat.2010.06.053

K. Gunasekaran, R. Annadurai, and P. S. Kumar, “A study on some durability properties of coconut shell aggregate concrete,” Material and Structures, vol. 48, pp. 1253-1264, 2015. DOI: https://doi.org/10.1617/s11527-013-0230-2

S. G. Bergström, and E. -H. Gram, “Durability of alkali-sensitive fibres in concrete,” International Journal of Cement Composites and Lightweight Concrete, vol. 6, pp. 75-80, 1984. DOI: https://doi.org/10.1016/0262-5075(84)90036-8

R. D. Tolêdo Filho, F. A. Silva, E. M. R. Fairbairn, and J. A. M. Filho, “Durability of compression molded sisal fiber reinforced mortar laminates,” Construction and Building Materials, vol. 23, pp. 2409–2420, 2009. DOI: https://doi.org/10.1016/j.conbuildmat.2008.10.012

H. Savastano, and P. G. Warden, R. S. P. Coutts, Microstructure and mechanical properties of waste fibre–cement composites, Cement and Concrete Composites, vol 27, pp. 583-592, 2005. DOI: https://doi.org/10.1016/j.cemconcomp.2004.09.009

H Savastano, P. G Warden, and R. S. P Coutts, “Brazilian waste fibres as reinforcement for cement-based composites,” Cement and Concrete Composites, vol 22, pp. 379-384, 2000. DOI: https://doi.org/10.1016/S0958-9465(00)00034-2

H Savastano, P. G Warden, and R. S. P Coutts, Potential of alternative fibre cements as building materials for developing areas, Cement and Concrete Composites, vol 25, pp. 585-592, 2003. DOI: https://doi.org/10.1016/S0958-9465(02)00071-9

H. Savastano, S. F. Santos, M. Radonjic, and W. O. Soboyejo, “Fracture and fatigue of natural fiber-reinforced cementitious composites,” Cement and Concrete Composites, vol 31, pp. 232-243,2009. DOI: https://doi.org/10.1016/j.cemconcomp.2009.02.006

T. Desthalumpoo, and A. Wannaharnon. “Appropriate ratio for using water hyacinth fibers for making cement fiberboard,” Princess of Naradhiwas University Journal, vol 12, pp. 262-276. 2020.

E.O. Ojo, M .Okwu, L. Edomwonyi-Out, and F. A. Oyawale. “Initial assessment of reuse of sustainable wastes for fibreboard production: the case of waste paper and water hyacinth,” Journal of Material Cycles and Waste Management, vol 21, pp. 1177-1187, 2019. DOI: https://doi.org/10.1007/s10163-019-00871-z

T. Jirawattanasomkul, H. Minakawa, S. Likitlersuang, T. Ueda, J. G. Dai, N. Wuttiwannasak, and N. Kongwang, “Use of water hyacinth waste to produce fibre-reinforced polymer composites for concrete confinement: Mechanical performance and environmental assessment,” Journal of Cleaner Production, vol 292, pp. 126041, 2021. DOI: https://doi.org/10.1016/j.jclepro.2021.126041

G. H. D. Tonoli, A. P. Joaquim, M-A. Arsène, K. Bilba, and H. Savastano Jr. “Performance and durability of cement based composites reinforced with refined sisal pulp,” Materials and Manufacturing Processes, vol 22, pp. 149-156, 2007. DOI: https://doi.org/10.1080/10426910601062065

L. C. Roma, L. S. Martello, and H. Savastano, “Evaluation of mechanical, physical and thermal performance of cement-based tiles reinforced with vegetable fibers,” Construction and Building Materials, vol 22, pp. 668-674, 2008. 34 DOI: https://doi.org/10.1016/j.conbuildmat.2006.10.001

H. Savastano, P. G Warden, and R. S. P Coutts, “Ground iron blast furnace slag as a matrix for cellulose-cement materials,” Cement and Concrete Composites, vol 23, pp. 389-397, 2001. DOI: https://doi.org/10.1016/S0958-9465(00)00083-4

J. Claramunt, M. Ardanuy, J. A. García-Hortal, and R.D.T. Filho, “The hornification of vegetable fibers to improve the durability of cement mortar composites,” Cement and Concrete Composites, vol 33, pp. 586-595, 2011. DOI: https://doi.org/10.1016/j.cemconcomp.2011.03.003

M. Khorami, and E. Ganjian, “Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus,” Construction and Building Materials, vol 25, pp. 3661-3667, 2011. DOI: https://doi.org/10.1016/j.conbuildmat.2011.03.052

R. C. Sun, and X. F. Sun, “Fractional and structural characterization of hemicelluloses isolated by alkali and alkaline peroxide from barley straw,” Carbohydrate Polymers, vol. 49, pp. 415-423, 2002. DOI: https://doi.org/10.1016/S0144-8617(01)00349-6

X. F. Sun, R. C. Su, Y. Su, and J. X. Sun, “Comparative study of crude and purified cellulose from wheat straw,” Journal of Agricultural and Food Chemistry, vol. 52, pp. 839-847, 2004. DOI: https://doi.org/10.1021/jf0349230

H. Chattopadhyay, and P. B. Sarkar. “A new method for the estimation of cellulose,” Proceedings of the National Institute of Sciences of India, vol 12, pp. 23-46, 1946.

P. B. Sarkar, A. K. Mazumdar, and K. B. Pal. “The hemicelluloses of jute fibre,” Journal of the Textile Institute Transactions, vol. 39, pp. 44-58, 1948. DOI: https://doi.org/10.1080/19447024808659401

W. G. Macmillan, A. B. Sengupta, and A. Roy. “Observations on the determination of lignin in jute,” Journal of the Textile Institute Transactions, vol. 43, pp. 103-107, 1952. DOI: https://doi.org/10.1080/19447025208659651

L. Segal, J. J. Creely, A. E. Martin Jr., and C. M. Conrad, “An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer,” Textile Research Journal, vol. 29, pp. 786-794, 1959. DOI: https://doi.org/10.1177/004051755902901003

Y. Nishiyama, S. Kuga, and T. Okano, “Mechanism of mercerization revealed by X-ray diffraction,” The Japan Wood Research Society, vol. 46, pp. 452-457, 2000. DOI: https://doi.org/10.1007/BF00765803

M. Thiripura, and A. Ramesh, “Isolation and characterization of cellulose nanofibers from the aquatic weed water hyacinth-Eichhornia crassipes,” Journal of Carbohydrate Polymers, vol. 87, pp. 1701-1705, 2012. DOI: https://doi.org/10.1016/j.carbpol.2011.09.076

M. A. Arsène, A. Okwo, K. Bilba, A. B. O. Soboyejo, and W. O. Soboyejo, “Chemically and thermally treated vegetable fibers for reinforcement of cement-based composites,” Materials and Manufacturing Processes, vol. 22, pp 214-227, 2007. DOI: https://doi.org/10.1080/10426910601063386

K. O. Reddy, B. R. Guduri, and A. V. Rajulu, “Structural characterization and tensile properties of Borassus fruit fibers,” Journal of Applied Polymer Science, vol. 114, pp. 603-611, 2009. DOI: https://doi.org/10.1002/app.30584

M. A. Paglicawan, B. S. Kim, B. A. Basilia, C. S. Emolaga, D. D. Marasigan, and P. E. C. Maglalang. “Plasma-treated abaca fabric/unsaturated polyester composite fabricated by vacuum-assisted resin transfer molding,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 1, pp. 241-246, 2014. DOI: https://doi.org/10.1007/s40684-014-0030-3

S. Saravanakumar, A. Kumaravel, T. Nagarajan, P. Sudhakar, and R. Baskaran, “Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark,” Carbohydrate polymers, vol. 92, pp. 1928-1933, 2013. DOI: https://doi.org/10.1016/j.carbpol.2012.11.064

S. Thomas, S. A. Paul, L. A. Pothan and B. Deepa “Natural fibres: structure, properties and applications” in Cellulose Fibers: Bio- and Nano-Polymer Composites, ed Berlin: Springer Heidelberg Dordrecht, 2011, pp. 33-42. DOI: https://doi.org/10.1007/978-3-642-17370-7_1

L. Jiang, J. J. Huang, J. Qian, F. Chen, J. Zhang, M. P. Wolcott, and Y. Zhu., “Study of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)(PHBV) bamboo pulp fiber composites: Effects of nucleation agent and compatibilizer,” Journal of Polymers and the Environment, vol. 16, pp. 83-93, 2008. DOI: https://doi.org/10.1007/s10924-008-0086-7

C. H. Lee, A. Khalina, S. H. Lee, F. N. M. Padzil, and Z. M. A. Ainun, “Physical, morphological, structural, thermal and mechanical properties of pineapple leaf fibers,” in Pineapple leaf fibers. Green energy and technology, ed Singapore: Springer, 2020, pp. 91-121. DOI: https://doi.org/10.1007/978-981-15-1416-6_6

N. Rambabu, S. Panthapulakkal, M. Sain, and A. K. Dalai, “Production of nanocellulose fibers from pinecone biomass: Evaluation and optimization of chemical and mechanical treatment conditions on mechanical properties of nanocellulose films,” Industrial Crops and Products, vol. 83, pp. 746-754, 2016. DOI: https://doi.org/10.1016/j.indcrop.2015.11.083

M. S. Huda, L. T. Drzal, A. K. Mohanty, and M. Misra, “Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites,” Composites Interfaces, vol. 15, pp. 169-191, 2008. DOI: https://doi.org/10.1163/156855408783810920

TAPPI T-264 CM-07 (2000) Preparation of wood for chemical analysis. TAPPI Press, Atlanta, GA

TAPPI T-203 CM-09 (2009) Alpha-, beta- and gamma-cellulose in pulp. TAPPI Press, Atlanta, GA

TAPPI UM 250 (1991) “Acid-soluble lignin in wood and pulp”, TAPPI Useful Method 250. TAPPI Press, Atlanta, GA.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.