Investigation of surface hardness and roughness on formability of aluminum alloy sheet AA2024-T3 subjected to the shot peening process by silica shots

DOI:

https://doi.org/10.55713/jmmm.v33i1.1594Keywords:

Shot peening, Aluminum alloy 2024-T3, Formability, Hole expansion test, Erichsen cupping testAbstract

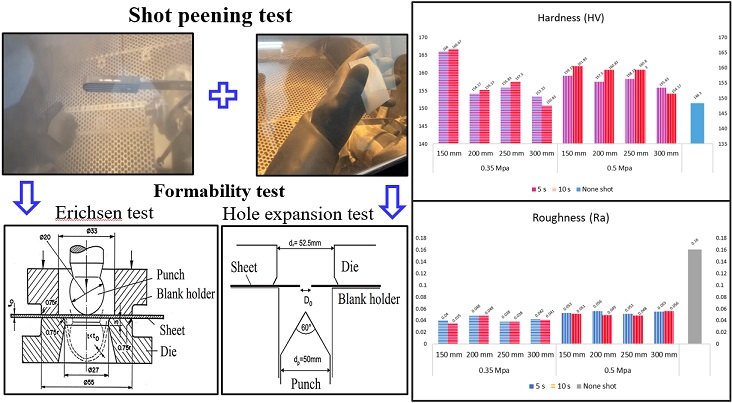

Shot peening is one type of modified surface treatment that produces a residual compressive stress on the material subsurface and improves surface properties while generating plastic deformation on the surface. This research work aims to improve surface properties, which include the enhanced material formability of aluminum alloy 2024-T3 sheet having 1.2 mm of thickness, by providing residual compressive stress on the surface using the shot peening process, which uses silica particles of 0.1 mm in diameter. First, shot peening was performed using various process parameters: compressed air, distance from nozzle to target, and duration time. Based on the obtained peening sheet, the surface hardness and roughness tests were experimentally performed on the peened surfaces. Additionally, the residual tension created in the sheet after the shot peening is calculated using the X-ray diffraction technique. Consequently, the shot-peened and unpeened sheets were put through hole expansion and Erichsen cupping tests to compare the results of the formability between the shot-peened and unpeened sheets. It was found that peened sheets had a low surface roughness and increased surface hardness, which is better than the unpeened sheet. Moreover, the residual compressive stresses were higher than on the original sheet. Last, the shot peening condition, which changed the surface properties the most, was tested on the hole expansion and Ericshen cupping tests, where the formability results were very significant.

Downloads

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.