High-temperature oxidation resistance of CrAlN thin films prepared by DC reactive magnetron sputtering

DOI:

https://doi.org/10.55713/jmmm.v33i3.1600Keywords:

high-temperature oxidation resistance, CrAlN thin films, sputteringAbstract

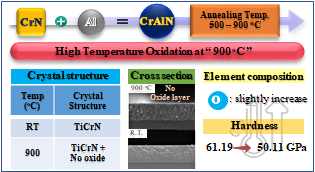

CrAlN thin films were prepared by using the reactive DC unbalanced magnetron sputtering method from the single alloy target on a silicon substrate. The effect of annealing temperature in the air which ranges from 500℃ to 900℃ for 1 h on phase structure, film composition, surface morphology, microstructure, and hardness was investigated by XRD, EDS, FE-SEM, and Nanoindentation techniques, respectively. The high-temperature (up to 900℃) oxidation resistance of the thin film was also evaluated. The result shows that solid solutions of (Cr,Al)N with (111), (200), and (220) planes for the as-deposited film and no oxide phase were found after annealing with different temperatures. The O content slightly increases with an increase in the annealing temperature with various Cr, Al, and N contents found by the EDS. From the FE-SEM result, as increased annealing temperature, the evolution of cross-sectional morphology from dense to compact columnar structure was exhibited but the oxides layer was not detected. These results concluded that the as-deposited thin film showed good oxidation resistance when annealed in air at an elevated temperature reaching 900℃. Moreover, the film’s hardness decreased from 61.19 GPa to 50.11 GPa with increasing the annealing temperature observed by the Nanoindentation technique.

Downloads

References

G. Abadias, L. E. Koutsokeras, A. Siozios, and P. Patsalas, "Stress, phase stability and oxidation resistance of ternary Ti–Me–N (Me= Zr, Ta) hard coatings," Thin Solid Films, vol. 583, pp. 56-70, 2013.

S. Xudong, L. Guojian,, J. Chenjie, W. Kai, Z Yingjie, H. Junying, and W. Qiang Su, "Improved toughness of layered architecture TiAlN/CrN coatings for titanium high speed cutting," Ceramics International, vol. 44, no. 5, pp. 5629-5635, 2018.

S. Raghavendra, and R. Asha, "Nanoscale TiO2 and Ta2O5 as efficient antireflection coatings on commercial monocrystalline silicon solar cell," Journal of Alloys and Compounds, vol. 826, pp. 158464, 2021.

H. Jiayi, L. Xuexia, L. Zhongwu, J, Dongling, Z. Xichun, C. Yitian, T. Chunmei, and Q. Wanqi, " Modification of Cr/CrN composite structure by Fe addition and its effect on decorative performance and corrosion resistance," Ceramics International, vol. 47, no. 17, pp. 23888-23894, 2021.

A. Sabana, G. Soumya, M. S. Siba, and K. M. Rinku, "Performance evaluation of CrAlN and TiAlN coatings deposited by HiPIMS in micro drilling of a Ni-based superalloy," Surface and Coatings Technology, vol. 449, pp. 128980, 2022.

K. Abdelkrim, S. Nadia, A. Seddik-El-Hak, and N. Corinne, "Effect of Ar/N2 flow ratio on the microstructure and mechanical properties of Ti-Cr-N coatings deposited by DC magnetron sputtering on AISI D2 tool steels," Surface and Coatings Technology, vol. 421, pp. 967-973, 2021.

A. Ebrahim, M. Monzer, B. Abdulkahim, C. David, A. Khan, and B. D. Baseer, "Optical and magnetic properties of cobalt doped TiN thin films grown by RF/DC magnetron sputtering," Journal of Magnetism and Magnetic Materials, vol. 550, pp. 169023, 2022.

L. Wang, S. Zhamg, Z. Chen, J. Li, and M. Li, "Influence of deposition parameters on hard Cr-Al-N coatings deposited by multi-arc ion plating," Applied Surface Science, vol. 258, pp. 3629-3636, 2012.

Z. Li, P. Munroe, Z. T. Jiang, X. Zhao, J. Xu, Z. F. Zhou, J. Q. Jiang, F. Fang, and Z. H. Xie, "Designing superhard, self-toughening CrAlN coatings through grain boundary engineering," Acta Materialia, vol. 60, pp. 5735-5744, 2012.

X. Ren, Z. Huang, M. Liu, and H. Chen, "Comparison of microstructure and tribological behaviors of CrAlN and CrN film deposited by DC magnetron sputtering," Rare Metal Materials and Engineering, vol. 47, no. 4, pp. 1100-1106, 2018.

B. Tlili, N. Mustapha, C. Nouveau, Y. Benlatreche, G. Guillemot, and M. Lambertin, "Correlation between thermal properties and aluminum fractions in CrAlN layers deposited by PVD technique," Vacuum, vol. 84, pp. 1067-1074, 2010.

A. Khumbun, A. Buranawong, and N. Witit-anun, "Structural characterization of reactive DC magnetron co-sputtered nano-crystalline CrAlN thin film," Key Engineering Materials, vol. 751, pp. 1662-1106, 2017.

D. Xing-Zhao and X. T. Zeng, "Structural, mechanical and tribological properties of CrAlN coatings deposited by reactive unbalanced magnetron sputtering," Surface & Coatings Technology, vol. 200, pp. 1372-1376, 2005.

A. Kayani, T. L. Buchanan, M. Kopczyk, C. Collins, J. Lucas, K. Lund, R. Hutchison P. E. Gannon, M. C. Deibert, R. J. Smith, D.-S. Choi, and V. I. Gorokhovsky, "Oxidation resistance of magnetron-sputtered CrAlN coatings on 430 steel at 800°C," Surface & Coatings Technology, vol. 201, pp. 4460-4466, 2006.

S. Khamseh, M. Nose, T. Kawabata, K. Matsuda, and S. Ikeno, "Oxidation resistance of CrAlN films with different micro-structures prepared by pulsed dc balanced magnetron sputtering system," Materials Transactions, vol. 51, no. 2, pp. 1662-1106, 2010.

S. Alaksanasuwan, A. Buranawong, and N. Witiy-anun, "Effect of sputtering current on structure of TiCrN thin films prepared from mosaic target by reactive DC magnetron sputtering," Applied Mechanics and Materials, vol. 901, pp. 37-42, 2020.

S. Zhou, R. Tan, X. Jiang, X. Shen, W. Xu, and W. Song, "Growth of CZTS thin films by sulfurization of sputtered single layered Cu–Zn–Sn metallic precursors from an alloy target," Journal of Materials Science: Materials in Electronics, vol. 24, pp. 4958-4963, 2013.

H. C. Barshilia, N. Selvakumar, B. Deepthi, and K. S. Rajam, "A comparative study of reactive direct current magnetron sputtered CrAlN and CrN coatings," Surface and Coatings Technology, vol. 201, no. 6, pp. 2193-2201, 2006.

J. Husn, M. M. Aliyu, M. A. Islam, P. Chelvanathan, N. R. Hamzah, M. S. Hossain, M. R. Karim, and N. Amin, “Influence of annealing temperature on the properties of ZnO thin films grown by sputtering,” Energy Procedia, vol. 25, pp. 55-61, 2012.

B. D. Cullity and S. R. Stock, Elements of X-ray diffraction. New Jersey: Prentice-Hall., 2001.

A. Jafari, Z. Ghoranneviss, A. S. Elahi, M. Ghoranneviss, N. F. Yazdi, and A. Rezaei, "Effects of annealing on TiN Thin film growth by DC magnetron sputtering," Advances in Mechanical Engineering, vol. 204, pp. 1-6, 2014.

J. Lin, B. Mishra, J. J. Moore, and W. D. Sproul, "A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses," Surface and Coatings Technology, vol. 202, pp. 3272-3283, 2008.

A. Anders, "A structure zone diagram including plasma-based deposition and ion etching," Thin Solid Films, vol. 518, no. 15, pp. 4087-4090, 2010.

J. Shlak, M. Tkadletz, and C. Mitterer, "Hard coating for cutting application: Physical vs. chemical vapor deposition and future challenge for the coating community," Surface and Coatings Technology, vol. 429, p. 127949, 2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.