The effects of copper on the mechanical properties of Ti-10Mo alloy prepared by powder metallurgy method

DOI:

https://doi.org/10.55713/jmmm.v34i1.1813Keywords:

Titanium alloy, Copper, Compression test, Hardness, Powder metallurgyAbstract

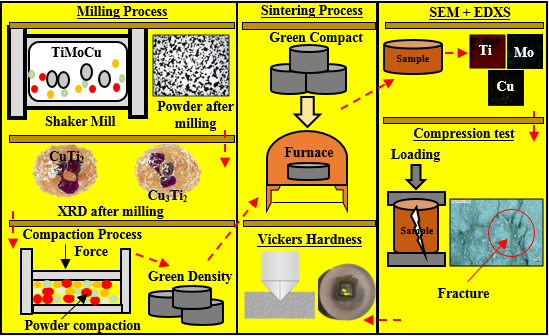

Titanium alloys are currently widely explored and produced for applications in various engineering fields. Alloying metal elements such as Mo, Cu, and Mn bring more advantages among them to help improve the mechanical properties of titanium alloys. This study is intended for the evaluation of mechanical properties through compression and hardness testing performed on a Ti-10Mo alloy with copper addition by powder metallurgy. Ti-10Mo alloys with the addition of copper contents of 3 wt% Cu, 6 wt% Cu, and 9 wt% Cu were prepared to optimize the properties of Ti-10Mo-xCu alloys. With the addition of 3 wt% copper, the compressive strength increased to 577 MPa, which is the maximum compressive strength in this study. On the other hand, with 6 wt% and 9 wt% Cu addition, the compressive strength became 140 MPa and 201 MPa, respectively. A Ti-10Mo alloy with a 3 wt% copper content was able to achieve the maximum hardness of 576 HV. In short, the addition of 3 wt% copper successfully increased the compressive strength as well as the hardness of the prepared titanium alloys.

Downloads

References

D. F. Williams, “Definitions in biomaterial,” Journal of Polymer Science Part C: Polymer Letters, vol.26, pp. 414-414, 1988.

M. Niinomi, “Biologically and mechanically biocompatible titanium alloys,” Materials Transactions, vol. 49, pp. 2170-2178, 2008.

M. Sarraf, E. R. Ghomi, S. Alipour, S. Ramakrishna, and N. L. Sukiman, “A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications,” Bio-Design and Manufacturing, vol. 5, pp. 371-395, 2021.

S. Omarov, N. Nauryz, D. Talamona, and A. Perveen, “Surface modification techniques for metallic biomedical alloys : A concise review,” Metals, vol. 13, pp. 1-52, 2022.

R. D. Carpenter, B. S. Klosterhoff, F. B. Torstrick, K.T. Foley, J. K. Burkus, C. S. D. Lee, K. Gall, R. E Guldberg, and D. L. Safranski, “Effect of porous orthopaedic implant material and structure on load sharing with simulated bone ingrowth: A finite element analysis comparing titanium and PEEK,” Journal of the Mechanical Behavior of Biomedical Materials, vol. 80, pp. 68-76, 2018.

M. L. Lourenco, G. C. Cardoso, K. D. S. Sousa, T. A. G. Donato, F. M. L. Pontes, and C. R. Grandini, “Development of novel Ti-Mo-Mn alloys for biomedical applications,” Scientific Reports, vol. 10, pp. 1-8, 2020.

C. C. Xavier, D. R. N. Correa, C. R. Grandini, and L. A Rocha, “Low temperature heat treatments on Ti-15Zr-xMo alloys,” Journal of Alloys and Compounds, vol. 727, pp. 246-253, 2017.

P. A. B. Kuroda, M. A. R. Buzalaf, and C. R. Grandini, “Effect of molybdenum on structure, microstructure and mechanical properties of biomedical Ti-20Zr-Mo alloys,” Materials Science and Engineering: C, vol. 67, pp. 511-515, 2016.

X. Mao, A. Shi, R. Wang, J. Nie, G. Qin, D. Chen, and E. Zhang, “The Influence of copper content on the elastic modulus and antibacterial properties of Ti-13Nb-13Zr-xCu Alloy,” Metals, vol. 22, pp. 1-20, 2022.

M. R. Akbarpour, H. M. Mirabad, A. Hemmati, and H. S. Kim, “Processing and microstructure of Ti-Cu binary alloys: A comprehensive review,” Progress in Materials Science, vol. 127, pp. 3306-3322, 2022.

M. Kaftaranova, V. Hodorenko, S. Anikeev, N. Artyukhova, A. V. Shabalina, and V. Gunther, “Investigation of the effect of copper addition on physical and mechanical properties of TiNi-Cu porous alloy,” Metals, vol. 10, pp. 1-12, 2022.

N. Hezil, L. Aissani, M. Fellah, M. A Samad, A. Obrosov, C. Timofei, and E. Marchenko, “Structural, and tribological properties of nanostructured α + β type titanium alloys for total hip,” Journal of Materials Research and Technology, vol. 19, pp. 3568-3578, 2022.

V. Eremenko, Y. Buyanov, and S. Prima, ”Phase diagram of the system titanum-copper,” Powder Metallurgy and Metal Ceramics, vol. 5, pp. 494-502, 1996.

P. Canale, and C. Servant, “Thermodynamic assesment of the Cu-Ti system taking into account the new stable phase CuTi3,” International Journal of Materials Research, vol. 93, pp. 273-276, 2002.

M. A. Rolando, and R. Malherbe, The Physics and Chemistry of Materials. New York: CRC Press Taylor & Francis Group., 2010.

S. F. Tikhov, K. R. Valeev, A. N. Salanov, S. V. Cherepanova, N. N. Boldyreva, V. I. Zaikovskii, V. A. Sadykov, D. V. Dudina, O. I. Lomovsky, V. E. Romanenkov, and E. E. Pyatsyushik, “Phase formation during high-energy ball milling of the 33Al-45Cu-22Fe (at%) powder mixture,” Journal of Alloys and Compounds, vol. 736, pp. 289-296, 2018.

J. L. Xu, L.Z. Bao, A. H. Liu, X. F. Jin, J.M. Luo, Z. C. Zhong, and Y. E. Zheng, “Effect of pore sizes on the microstructure and properties of the biomedical porous NiTi alloys prepared by microwave sintering,” Journal of Alloys and Compounds, vol.645, pp. 137-142, 2015.

J. Li, N. Yu, H. Jiang, J. Leng, and H. Geng, “Effects of annealing temperature on dealloying of Ti-Cu alloy,” Corrosion Scicence, vol.91, pp. 95-100, 2015.

S. Vazirian, and A. Farzadi, “Dissimilar transient liquid phase bonding of Ti-6Al-4V and Co-Cr-Mo biomaterials using a Cu interlayer: Microstructure and mechanical properties,” Journal of Alloys and Compounds, vol. 829, pp. 1-10, 2020.

C. Yi, Z. Ke, L. Zhang, J. Tan, Y. Jiang, and Z. Y. He, “Antibacterial Ti-Cu alloy with enhanced mechanical properties as implant applications,” Materials Research Express, vol.7, pp. 1-10, 2020.

M. J. Donachie, “Titanium a technical guide,” The Material Information Society, 2nd ed. United States of America: ASM International., 2000.

H. Hao, Y. Wang, H. R. J. Nodooshan, Y. Zhang, S. Ye, Y. Lv, and P. Yu, “The efects of sintering temperature and addition of TiH2 on the sintering process of Cu,” Materials, vol.12, no. 16, p. 2594, 2019.

Y. Cong, T. Bhattacharjee, J. Yi, and S. Zhao, “Achieving bi-lamellar microstructure with both high tensile strength and large ductility in Ti-6Al-4V alloy by novel thermomechanical processing,” Materialia, vol. 8, pp. 1-11, 2019.

S. B. Li, and J. X. Xie, “Processing and microstructure of functionally graded W/Cu composites fabricated by multi-billet extrusion using mechanically alloyed powders,” Composites Science and Technology, vol.66, pp. 2329-2336, 2006.

G. C. Kuczynski, “Sintering and related phenomena ostwald ripening-A Survey,” Proc. MSR., 3th International Conference on Sintering and Related Phenomena., Boston, USA, Jun. 5-7, 1972.

W. Xu, C. Hou, Y. Mao, L. Yang, M. Tamaddon, J. Zhang, Z. Qu, C. Liu, B. Su, and X. Lu, “Characteristics of novel Ti-10Mo-xCu alloy by powder metallurgy for potential biomedical implant applications,” Bioactive Materials, vol.5, pp. 659-666, 2020.

S. M. Javadhesari, S. Alipour, and M. R. Akbarpour, “Bio-compatibility, osseonintegration, antibacterial and mechanical properties of nanocrystalline Ti-Cu alloy as a new orthopedic material,” Colloids and Surface B: Biointerfaces, vol.189, pp. 1-9, 2020.

W. Dang, S. Ren, J. Zhou, Y. Yu, Z. Li and L. Wang, “Influence of Cu on the mechanical and tribological properties of Ti3SiC2,” Ceramics International, vol.42, pp. 9972-9980, 2016.

Z. Gao, H. Luo, and Q. Li, “Preparation and characterization of Ti-10Mo alloy by mechanical alloying,” Metallography, Microstructure, and Analysis, vol. 1, pp. 282-289, 2012.

S. C. Tao, J. L. Xu, J. M. Luo, and Y.F. Zheng, “Micro-structure, mechanical properties and antibacterial properties of the microwave sintered porous Ti-3Cu alloy,” Journal of Alloys and Compounds, vol.812, pp. 1-9, 2020.

Z. Wang, B. Fu, Y. Wang, T. Dong, J. Li, G. Li, X. Zhao, J. Liu, and G. Zhang, “Effect of Cu content on the precipitation behaviors, mechanical and corrosion properties of As-Cast Ti-Cu alloys,” Materials, vol. 15, pp. 1-16, 2022.

O. Ashkani, M. R. Tavighi, M. Karamimoghadam, M. Moradi, M. Bodaghi, and M. Rezayat, “Influence of aluminum and copper on mechanical properties of biocompatible Ti-Mo Alloys: A simulation-based investigation,” Micromachines, vol 14, pp. 1-13, 2023.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.