Effects of milling time on sintering properties and formation of interface Al4C3 on graphite reinforced Al-4.5Cu-1.5Mg nanocomposite

DOI:

https://doi.org/10.55713/jmmm.v32i1.1132Keywords:

Alumunium, Graphite, Nanocomposite, Shaker Mill, , SinteringAbstract

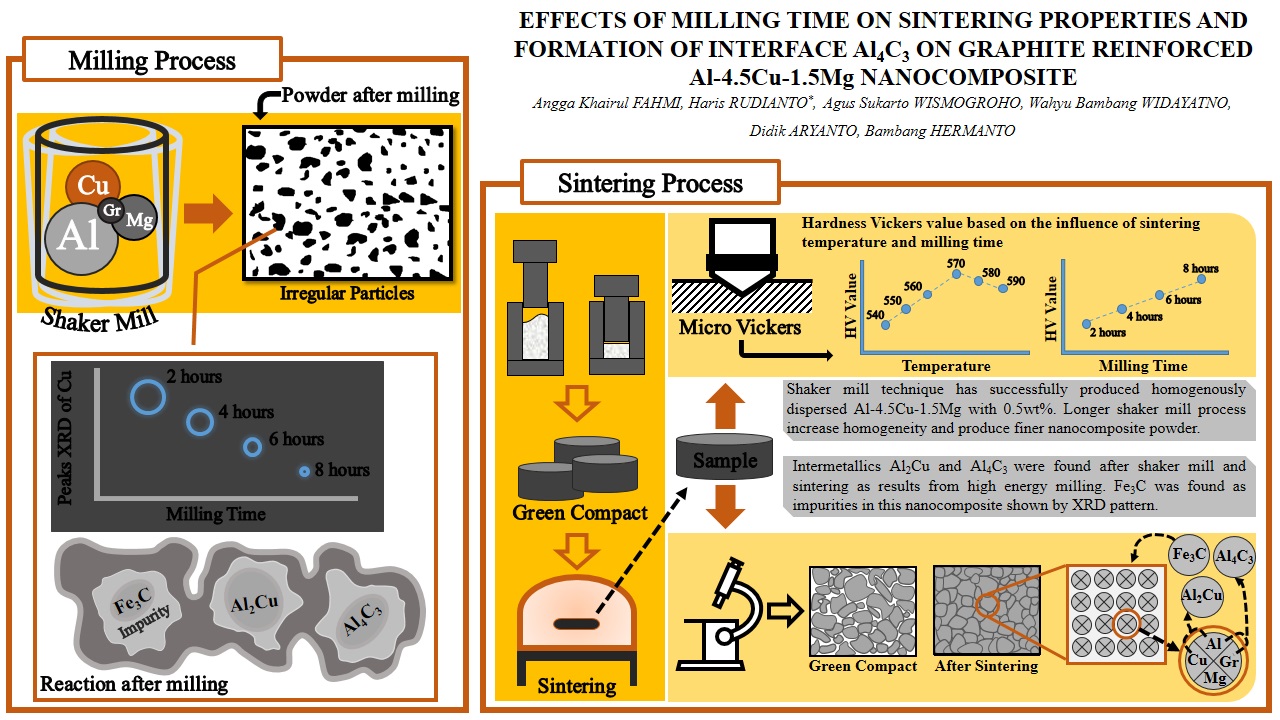

Aluminum-based metal matrix nanocomposites have been extensively researched and developed for aerospace and automotive applications. Al-4.5Cu-1.5Mg with 0.5 wt% graphite were milled for 2 h, 4 h, 6 h, and 8 h using shaker mill under argon gas. The phenomena of deformation, fracturing, and cold welding during shaker mill were investigated to observe how the shaker mill effects on their morphology and formation of intermetallic phases due to its very high speed. Sintering under ultra-high purity argon gas for 99.9999% was done to produce high density materials. Intermetallic phase Al4C3 was found as a result reaction between aluminum and graphite during milling. Formation of Al4C3 is very important to the alloy as an interface between matrix and reinforcement particle in order to have higher hardness. A decrease in Peaks Cu and followed by an increase in Al2Cu precipitation in the XRD pattern occurred with increasing milling time. The role of Al2Cu precipitation is very important in improving mechanical properties, resulting in the highest hardness value reaching 97 HV and a density value of 83% at 8 h of milling.

Downloads

References

R. Pérez-Bustamante, M. J. González-Ibarra, J. González-Cantú, I. Estrada-Guel, J. M. Herrera-Ramírez, M. Miki-Yoshida, and R. Martínez-Sánchez, “AA2024-CNTs composites by milling process after T6-temper condition,” Journal of Alloys and Compounds, vol. 536S, pp. S17-S20, 2012.

H. Ahamed, and V. Senthilkumar, “Consolidation behavior of mechanically alloyed aluminum based nanocomposites reinforced with nanoscale Y2O3/Al2O3 particles,” Materials Characterization, vol. 62, pp. 1235-1249, 2011.

P. Kumar H. G., and A. Xavior M., “Assessment of mechanical and tribological properties of Al 2024-SiC-Graphene hybrid composites,” Procedia Engineering, vol. 174, pp. 992-999, 2017.

A. Xavior, M. P. Kumar H. G, and A. Kumar. K, “Tribological studies on AA 2024-Graphene/CNT nanocomposites processed through Powder metallurgy,” Materials Today: Proceedings, vol. 5, pp. 6588-6596, 2018.

ASM Handbook Volume 2: Properties and selections: Nonferrous alloys and special-purpose materials, United States of America: ASM International, 1990.

L. Ceschini, A. Morri, and F. Rotundo, “Forming of metal matrix composites,” Comprehensive Materials Processing. Bologna: Elsevier pp. 159-186, 2014.

S. E. Hernández-Martinez, J. J. Cruz-Rivera, C. G. Garay-Reyes, R. Martínez-Sánchez, I. Estrada-Guel, and J. L. Hernández-Rivera, “Comparative study of synthesis of AA 7075-ZrO2 metal matrix composite by different mills,” Journal of Alloys and Compounds, vol. 643, pp. S107-S113, 2015.

J. L. Hernandez R., J. J. Cruz R., C. Gomez Y, O. Coreno A., and R. Martınez-Sanchez, “Synthesis of graphite reinforced aluminum nanocomposite by mechanical alloying,” Materials Transactions, vol. 51, no. 6, pp. 1120-1126, 2010.

J. B. Fogagnolo, F. Velasco, M. H. Robert, and J. M. Torralba, “Effect of mechanical alloying on the morphology, micro-structure and properties of aluminium matrix composite powders,” Materials Science and Engineering A, vol. 342, pp. 131-143, 2003.

A. Alizadeh, M. Maleki, and A. Abdollahi, “Preparation of super-high strength nanostructured B4C reinforced Al-2Cu aluminum alloy matrix composites by mechanical milling and hot press method: Microstructural, mechanical and tribological characterization,” Advanced Powder Technology, vol. 28, pp. 3274-3287, 2017.

S. F. Tikhov, K. R. Valeev, A. N. Salanov, S. V. Cherepanova, N. N. Boldyreva, V. I. Zaikovskii, V. A. Sadykov, D. V. Dudina, O. I. Lomovsky, V. E. Romanenkov, and E. E. Pyatsyushik, “Phase formation during high-energy ball milling of the 33Al-45Cu-22Fe (at%) powder mixture,” Journal of Alloys and Compounds, vol. 736, pp. 289-296, 2018.

A. Santos-Beltrán, V. Gallegos-Orozco, R. Goytia Reyes, M. Miki-Yoshida, I. Estrada-Guel, and R. Martínez-Sánchez, “Mechanical and microstructural characterization of dispersion strengthened Al-C system nanocomposites,” Journal of Alloys and Compounds, vol. 489, no. 2, pp. 626-630, 2010.

J. B. Fogagnolo, D. Amador, E. M. Ruiz-Navas, and J. M. Torralba, “Solid solution in Al-4.5 wt% Cu produced by mechanical alloying,” Materials Science and Engineering A, vol. 433, pp. 45-49, 2006.

C. Dhadsanadhep, T. Luangvaranunt, J. Umeda, and K. Kondoh, “Fabrication of Al/Al2O3 composite by powder metallurgy method from aluminum and rice husk ash,” Journal of Metals, Materials and Minerals, vol.18 (2), pp. 99-102, 2008.

W. Xu, W. Chenchong, Z. Zhichao, L. Ping, S. Yanhua, and Z. Guofu, “Interfacial microstructure and growth mechanism of Al4C3 in Grf/Al composites fabricated by liquid pressure method,” Micron, vol. 65, pp. 10-14, 2014.

H. Rudianto, S. S. Yang, Y. J. Kim, and K. W. Nam, “Sintering behavior of hypereutectic aluminum-silicon metal matrix composites powder,” International Journal of Modern Physics: Conference Series, vol. 6, pp. 628-633, 2012.

J. Wang, L. N. Guo, W. M. Lin, J. Chen, C. L. Liu, S. D. Chen, S. Zhang, and T. T. Zhen, “Effect of the graphene content on the microstructures and properties of graphene/aluminum composites,” New Carbon Materials, vol. 34, no. 3, pp. 275-285, 2019.

A. Gökçe, F. Findik, and A. O. Kurt, “Sintering and aging behaviours of Al-4Cu-XMg PM alloy,” The Canadian Journal of Metallurgy and Materials Science, vol. 55, no. 4, pp. 391-401, 2016.

Z. Y. Liu, T. B. Sercombe, and G. B. Schaffer, “The effect of particle shape on the sintering of aluminum,” Metallurgical and Materials Transactions A, vol. 38A, pp. 1351-1357, 2007.

M. Wu, Y. Liu, Z. Zeng, and W. Luo, “Effect of temperature on deformation behavior of sintered porous AA2024 during semisolid compression,” The Minerals, Metals & Materials Society, vol. 69, no. 4, pp. 763-769, 2017.

R. N. Lumley, T. B. Sercombe, and G. M. Schaffer, “Surface oxide and the role of magnesium during the sintering of aluminum,” Metallurgical and Materials Transactions A, vol. 30, pp. 457-463, 1999.

T. Pieczonka, Th. Schubert, S. Baunack, B. Kieback, “Dimensional behavior of aluminum sintered in different atmospheres,” Materials Science and Engineering A, vol. 478, no. 1-2, pp. 251-256, 2008.

C. Suryanarayana, “Mechanical alloying and milling,” Progress in Materials Science, vol. 46, pp. 1-184, 2001.

H. Rudianto, G. J. Jang, S. S. Yang, Y. J. Kim, and I. Dlouhy, “Effect of SiC particles on sinterability of Al-Zn-Mg-Cu P/M alloy,” Archives of Metallurgy and Materials, vol. 60, no. 2, pp. 1383-1385, 2015.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.