Rice husk ash utilization, composition and properties: A brief review

DOI:

https://doi.org/10.55713/jmmm.v32i4.1544คำสำคัญ:

Rice Husk Ash (RHA), Fillers, Water treatment, Filter, Compositesบทคัดย่อ

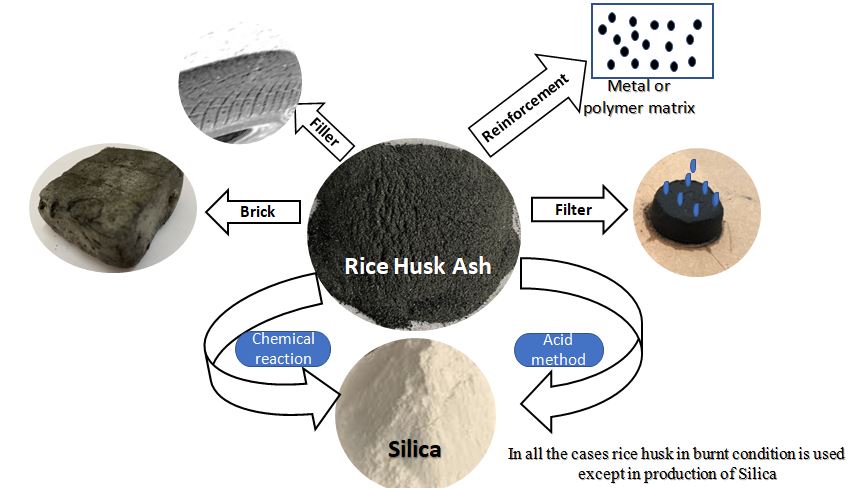

Asian countries rely massively on rice to feed and sustain its massive population. For long the staple food has provided nourishment to the masses and the classes. Rice is grown in large quantities in Asian countries. A by-product of its cultivation is its husk. The husk of the rice grain is mainly utilized as a fuel for the boilers in the rice mills. The uncontrolled burnt rice husk referred to as rice husk ash consists majorly of silica. silica is used in a wide variety of commercial and industrial applications. Use of rice husk ash in various products serves to reduce the pollution caused by its pileup in localities especially close to the rice mills. More sustainable and an affordable source of Si would benefit the society rather than disposing rice husk ash in the fields and landfills. This brief review provides insights into the synthesis, applications, and properties of rice husk ash incorporated products either directly in the as received conditions or under modified conditions.

Downloads

เอกสารอ้างอิง

“Top 10 rice producing states in india-largest rice producer,”

Blog - Tractor Junction, 01-Apr-2022. [Online]. Available: https:// www.tractorjunction.com/blog/top-10-rice-producing-states-in-india/. [Accessed: 23-Sep-2022].

N. Phonphuak and P. Chindaprasirt, “Types of waste, properties, and durability of pore-forming waste-based fired masonry bricks",” Eco-efficient masonry bricks and blocks, pp. 103-127, 2015.

A. Daulay, and S. Gea, “Effect of variation temperature at burning rice husk to obtain silica,” in AIP Conference Proceedings, vol. 2342, AIP Publishing LLC, 2021.

S. K. Shukla, “Rice husk derived adsorbents for water purification,” in Green Materials for Wastewater Treatment, Springer International Publishing, 2020, pp. 131-148.

T.-H. Liou, and P.-Y. Wang, “Utilization of rice husk wastes in synthesis of graphene oxide-based carbonaceous nano-composites,” Waste management, vol. 108, pp. 51-61, 2020.

O. S. Olusesi, and N. E. Udoye, “Development and characterization of AA6061 aluminium alloy/clay and rice husk ash composite,” Manufacturing Letters, vol. 29, pp. 34-41, 2021.

“TIMEIS,” Techno-preneur.net. [Online]. Available: https:// www.techno-preneur.net/technology/new-technologies/ chemicals-tec/sodium.html.

L. Sun, and K. Gong, “Silicon-based materials from rice husks and their applications,” Industrial & engineering chemistry research, vol. 40, no. 25, pp. 5861-5877, 2001.

C. Real, M. D. Alcala, and J. M. Criado, “Preparation of silica from rice husks,” Journal of the American Ceramic Society, vol. 79, no. 8, pp. 2012-2016, 1996.

U. Kalapathy, A. Proctor, and J. Shultz, “An improved method for production of silica from rice hull ash,” Bioresource technology, vol. 85, no. 3, pp. 285-289, 2002.

M. Rozainee, S. P. Ngo, A. A. Salema, and K. G. Tan, “Effect of feeding methods on the rice husk ash quality in a fluidised bed combustor,” Emirates Journal for Engineering Research, vol. 15, pp. 1-12, 2010.

I. J.Fernandes, D. Calheiro, A. G. Kieling, C. A. M.Moraes, T. L. .A.C.Rocha, F. A.Brehm, R.and C.E.Modolo,“Characterization of rice husk ash produced using different biomass combustion techniques for energy,” Fuel, vol. 165, pp. 351-359, 2016.

V. I. Kuprianov, R. Kaewklum, K. Sirisomboon, P. Arromdee, and S. Chakritthakul, “Combustion and emission characteristics of a swirling fluidized-bed combustor burning moisturized rice husk,” Applied Energy, vol. 87, no. 9, pp. 2899-2906, 2010.

R. Blissett, R. Sommerville, N. Rowson, J. Jones, and B. Laughlin, “Valorisation of rice husks using a TORBED® combustion process,” Fuel Processing Technology, vol. 159, pp. 247-255, 2017.

D. K. Bangwar, A. Saand, M. A. Keerio, M. A. Soomro, and N. Bhatti, “Development of an amorphous silica from rice husk waste. Engineering,” Technology & Applied Science Research, vol. 7, no. 6, pp. 2184-2188, 2017.

L. Armesto, A. Bahillo, K. Veijonen, A. Cabanillas, and J. Otero, “Combustion behaviour of rice husk in a bubbling fluidised bed,” Biomass Bioenergy, vol. 23, no. 3, pp. 171-179, 2002.

M. A. Hamad and I. A. Khattab, “Effect of the combustion process on the structure of rice hull silica,” Thermochimica Acta, vol. 48, no. 3, pp. 343-349, 1981.

D. D. Bui, J. Hu, and P. Stroeven, “Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete,” Cement and concrete composites, vol. 27, no. 3, pp. 357-366, 2005.

I. Johari, S. Said, R. P. Jaya, B. H. A. Bakar, and Z. A. Ahmad, “Chemical and physical properties of fired-clay brick at different type of rice husk ash,” International Conference on Environmental Science and Engineering, vol. 8, pp. 171-174, 2011.

R. Sigalingging, E. Susanto, and S. Panggabean, “The effect of rice husk mass on temperature and characteristics of its ash using a pyrolysis equipment organic-inorganic waste,” Conference Series: Earth and Environmental Science, vol. 454, no. 1, p. 012043, 2020.

F. Andreola, I. Lancellotti, T. Manfredini, F. Bondioli, and L. Barbieri, “Rice husk ash (RHA) recycling in brick manufacture: Effects on physical and microstructural properties,” Waste Biomass Valorization, vol. 9, no. 12, pp. 2529-2539, 2018.

A. A. M. Damanhuri, A. M. H. S. Lubis, A. Hariri, S. G. Herawan, M. H. I. Roslan, and M. S. F. Hussin, “Mechanical properties of rice husk ash (rha) brick as partial replacement of clay,” Journal of Physics: Conference Series, vol. 1529, no. 4, p. 042034, 2020.

J. Sutas, A. Mana, and L. Pitak, “Effect of rice husk and rice husk ash to properties of bricks,” Procedia Engineering, vol. 32, pp. 1061-1067, 2012.

R. S. Huq, and C. Farhana, “Use of rice husk ash as substitute to make clay bricks,” International Journal of Engineering Research and Applications, no. 10, 2018.

E. M. M. Ewais, R. M. Elsaadany, A. A. Ahmed, N. H. Shalaby, and B. E. H. Al-Anadouli, “Insulating refractory bricks from water treatment sludge and rice husk ash,” Refractories and Industrial Ceramics, vol. 58, no. 2, pp. 136-144, 2017.

N. H. Thang, “Novel porous refractory synthesized from diatomaceous earth and rice husk ash,” Journal of Polymer Composites, vol. 8, pp. 128-137, 2020.

D. Silva, E. Pachla, E. Marangon, M. Tier, and A. P. Garcia, “Effects of rice husk ash and wollastonite incorporation on the physical and thermal properties of refractory ceramic composites,” Matéria(Rio de Janeiro), vol. 25, no. 3, 2020.

M. N. Abdullah, M. Mustapha, N. Sallih, A. Ahmad, F. Mustapha, and A. Dahliyanti, “Study and use of rice husk ash as a source of aluminosilicate in refractory coating,” Materials (Basel), vol. 14, no. 13, p. 3440, 2021.

S. K. S. Hossain, L. Mathur, P. Singh, and M. R. Majhi, “Preparation of forsterite refractory using highly abundant amorphous rice husk silica for thermal insulation,” Journal of Asian Ceramic Societies, vol. 5, no. 2, pp. 82-87, 2017.

S. K. S. Hossain and P. K. Roy, “Fabrication of sustainable insulation refractory: Utilization of different wastes,” Boletín de la Sociedad Española de Cerámica y Vidrio, vol. 58, no. 3, pp. 115-125, 2019.

G. Berkin, “Heat absorbing glass from rice husk ash for a sustainable environment,” in Waste Management and the Environment IV, 2008.

“India population (2022) - worldometer,” Worldometers.info. [Online]. Available: https://www.worldometers.info/world-population/india-population/.

http://ttps://www.worldometers.info/world-population/india-population/

“How water pollution in India kills millions,” BORGEN, 14-Jul-2020. [Online]. Available: https://www.borgenmagazine.com/ water-pollution-in-india/.

“Ground water quality features of the country,” Gov.in. Available: http://cgwb.gov.in/WQ/GROUND%20WATER%20QUALITY%20SCENARIO%20IN%20INDIA.pdf

S. Bang and X. Meng, “Research papers : A review of arsenic interactions with anions and iron hydroxides,” Environmental Engineering Research, vol. 9, no. 4, pp. 184-192, 2004.

C. Malhotra, R. Patil, S. Kausley, and D. Ahmad, “Novel uses of rice-husk-ash (a natural silica-carbon matrix) in low-cost water purification applications,” AIP Conference Proceedings, vol. 1538, no. 1, pp. 113-119, 2013.

Ground water quality features of the country, Central ground water board report.2020.

A. Bivins, S. Lowry, H. M. Murphy, M. Borchardt, R. Coyte, P. Labhasetwar, and J. Brown, “Waterborne pathogen monitoring in Jaipur, India reveals potential microbial risks of urban groundwater supply,” npj clean water, vol. 3, no. 1, 2020.

S. Asadi, and F. Moeinpour, “Inactivation of Escherichia coli in water by silver-coated NiO. 5ZnO. 5Fe2O4 magnetic nanocomposite: a Box-Behnken design optimization,” Applied Water Science, vol. 9, no. 1, pp. 1-9, 2019.

“Tata uses nano technology for water purifier,” Cseindia.org. [Online]. Available: https://www.cseindia.org/tata-uses-nano- technology-forwater-purifier-852.

A. M. Gutierrez, D. Hotza, G. B. Dutra, A. L. Nogueira, C. V. Franco, W. Acchar, and C. R. Rambo, “Rice husk ash impregnated with silver nanoparticles for water purification,” Materials Science Forum, vol. 798-799, pp. 727-731, 2014.

D. Longano, N. Ditaranto, L. Sabbatini, L. Torsi, and N. Cioffi, “Synthesis and antimicrobial activity of copper nanomaterials,” in Nano-Antimicrobials, Berlin, Heidelberg: Springer Berlin Heidelberg, 2012, pp. 85-117.

Z. Ferdous and A. Nemmar, “Health impact of silver nanoparticles: A review of the biodistribution and toxicity following various routes of exposure,” International Journal of Molecular Sciences, vol. 21, no. 7, p. 2375, 2020.

J. Barajas, J. Latayan, S. Pagsuyoin, F. Bacani, J. Santos, R. Tan, A. Orbecido, L. Razon, and M. Almendrala, “Water disinfection using moringa protein adsorbed on rice husk ash,” in 2016 IEEE Systems and Information Engineering Design Symposium (SIEDS), 2016.

X. Han, J. Liang, S. Fukuda, L. Zhu, and S. Wang, “Sodium alginate–silica composite aerogels from rice husk ash for efficient absorption of organic pollutants,” Biomass and Bioenergy, vol. 159, p. 106424, 2022.

S. B. Daffalla, H. Mukhtar, and M. S. Shaharun, “Preparation and characterization of rice husk adsorbents for phenol removal from aqueous systems,” PLoS One, vol. 15, no. 12, p. e0243540, 2020.

J. O. Madu, F. V. Adams, B. O. Agboola, B. D. Ikotun, and I. V. Joseph, “Purifications of petroleum products contaminated water using modified rice husk ash filters,” Materials Today: Proceedings, vol. 38, pp. 599-604, 2021.

A. K. Priya., V.Yogeshwaran, S. Rajendran, T. K. A.Hoang, M. Soto-Moscosoe A. A. Ghfarf, and C. Bathula,“Investigation of mechanism of heavy metals (Cr6+, Pb2+& Zn2+) adsorption from aqueous medium using rice husk ash: kinetic and thermodynamic approach,” Chemosphere, vol. 286, 2022.

A. Anjitha, and D. Goerge, “Comparative study using rice husk and its ash as natural coagulants in waste water treatment," International Journal of Scientific and Engineering Research, vol. 7, no. 4, pp. 232-237, 2016.

M. Ali, and A. A-Ali Drea, “Green synthesis and characterization of antibiotic amorphous nano silicon oxide powder extracted from rice husk ash,” International Journal of Current Research and Review, vol. 13, no. 24, pp. 94-99, 2021.

L. Ravindran, K. Jesitha, P. U. Megha, S. Anilkumar, M. S. Sreekala, and P. S. Harikumar, “Nanosilica entrapped alginate beads for the purification of groundwater contaminated with bacteria," Silicon, pp. 1-14, 2022.

R. B. Seymour, “The role of fillers and reinforcements in plastics technology," Polymer-Plastics Technology and Engineering, vol. 7, no. 1, pp. 49-79, 1976.

D. S. Chaudhary, M. C. Jollands, and F. Cser, “Understanding rice hull ash as fillers in polymers: A review,” Silicon Chemistry, vol. 1, no. 4, pp. 281-289, 2002.

K. Song, “Micro-and nano-fillers used in the rubber industry,” in Progress in Rubber Nanocomposites, Woodhead Publishing, 2017, pp. 41-80.

C. D. M. Dominic, A. Balan, K. V. Neenu, P. M. S. Begum, D. Joseph, P. Dileep, R. Joseph, M. J. Jaison, M. Mathew, C. S. Dhanya, M. Badawi, and J. Parameswaranpillai, “Sustainable Kerala rice husk ash for formulation of basic tyre tread: Taking first step,” Sustainable Materials and Technologies, vol. 32, 2022.

V. C. Sethuramalingam, S. Prabagaran, and K. Ganesan, “Studies on influence of silica filler and rice husk ash on the mechanical properties of vulcanized hybrid rubber composite," Materials Today: Proceedings, vol. 37, pp. 2207-2213, 2021.

J. Suwanprateeb, and K. Hatthapanit, “Rice-husk-ash-based silica as a filler for embedding composites in electronic devices,” Journal of applied polymer science, vol. 86, no. 12, pp. 3013-3020, 2002.

N. S. Chundawat, B. S. Parmar, A. S. Deuri, D. Vaidya, S. Jaduon, P. Zarrintaj, M. Barani, and N. P. S. Chauhan “Rice husk silica as a sustainable filler in the tire industry,” Arabian Journal of Chemistry, vol. 15, no. 9, p. 104086, 2022.

M. R. S. Fernandes, A. M. F. de Sousa, and C. R. G. Furtado, “Rice husk ash as filler in tread compounds to improve rolling resistance,” Polímeros, vol. 27, no. 1, pp. 55-61, 2017

A. Boonmee, P. Sabsiriroht, and K. Jarukumjorn, “Preparation and characterization of rice husk ash for using as a filler in natural rubber,” Materials Today: Proceedings, vol. 17, pp. 2097-2103, 2019.

S. Burhan, M. Abed, M. Salih, Karbala Iraq, and Al-Furat, “Rice husk ash as a nano-filler to synthesize thermosetting polymer nanocomposites and evaluation of its tribological behavior,” Kufa Journal of Engineering., vol. 10, no. 1, pp. 78-91, 2019.

Rahmaniar, and T. Susanto, “Impacts of rice husk ash filler loading on curing, morphological characteristics and tensile properties of natural rubber/ethylene propylene rubber blends,” IOP Conference Series: Materials Science and Engineering, vol. 509, p. 012116, 2019.

Z. Zeng, Y. Li, P. Zhao, and H. Yu, “Fabrication of rice husk ash/natural rubber composites by the latex process,” Journal of Wuhan University of Technology (Materials Science Edition), vol. 35, no. 1, pp. 42-46, 2020.

D. Iluppalla, S. Ranatunga, and S. Siriwardena, “Silica/white rice husk ash hybrid filler for rubber composites for the manufacture of low speed castor wheel rubber treads,” Journal of the Rubber Research Institute of Sri Lanka, vol. 100, p. 38, 2020.

D. Dechojarassri, N. Ratikant, S. Charoenrat, and P. Danwanichakul, “Mechanical properties of natural rubber composites filled with starch sludge compared with other waste and commercial fillers,” IntInternational Journal of Chemical Engineering and Applications, vol. 8, no. 3, pp. 210-215, 2017.

W. Pongdong, C. Nakason, C. Kummerlöwe, and N. Vennemann, “Influence of filler from a renewable resource and silane coupling agent on the properties of epoxidized natural rubber vulcanizates,” Journal of Chemistry, vol. 2015, pp. 1-15, 2015.

E. P. Ayswarya, A. B. Nair, and E. T. Thachil, “A comparative study of mechanical, dynamic mechanical and thermal properties of rice husk ash, modified rice husk ash and nano silica filled epoxy composites,” Materials Today: Proceedings, vol. 47, pp. 5351–5357, 2021.

O. S. Olusesi, and N. E. Udoye, “Development and characterization

of AA6061 aluminium alloy/clay and rice husk ash composite," Manufacturing Letters, vol. 29, pp. 34-41, 2021.

N. E. Udoye, A. O. Inegbenebor, and O. S. I. Fayomi, “The analysis on electrical conductivity of AA6061/rice husk ash composites,” Materials Today: Proceedings, vol. 43, pp. 2245-2249, 2021.

A. Bahrami, N. Soltani, M. I.Pech-Canul, S. Soltani, L. A. González, C. A. Gutiérrez, J. Tapp, A. Möller, and A. Gurlo, “Bilayer graded Al/B4C/rice husk ash composite: Wettability behavior, thermo-mechanical, and electrical properties,” Journal of Composite Materials, vol. 52, no. 27, pp. 3745-3758, 2018.

P. P. Kulkarni, and B. Siddeswarappa, “A study on microstructure and mechanical behaviour of AA6063 metal matrix composite reinforced with areca sheath ash (ASA) and rice husk ash (RHA),” Materials Today: Proceedings, vol. 52, pp. 445-451, 2022.

M. P. Chakravarthy, and D. Santha Rao, “Evaluation of mechanical properties of aluminium alloy (AA 6082) reinforced with rice husk ash (RHA) and boron carbide (B4C) hybrid metal matrix composites using stir casting method,” Materials Today: Proceedings, vol. 66, pp. 580-586, 2022.

N. E. Udoye, O. J. Nnamba, O. S. I. Fayomi, A. O. Inegbenebor, and K. J. Jolayemi, “Analysis on mechanical properties of AA6061/Rice husk ash composites produced through stir casting technique,” Materials Today: Proceedings, vol. 43, pp. 1415-1420, 2021.

A. Kumar and M. Kumar, “Mechanical and dry sliding wear behaviour of B4C and rice husk ash reinfroced Al 7075 alloy hybrid composite for armors application by using taguchi techniques,” Materials Today: Proceedings, vol. 27, pp. 2617-2625, 2020.

M. B. N. Shaikh, S. Arif, T. Aziz, A. Waseem, M. A. N. Shaikh, and M. Ali, “Microstructural, mechanical and tribological behaviour of powder metallurgy processed SiC and RHA reinforced Al-based composites,” Surfaces and Interfaces, vol. 15, pp. 166-179, 2019.

A. M. Usman, A. Raji, N. H. Waziri, and M. A. Hassan, “Aluminium alloy-rice husk ash composites production and analysis,” Leonardo Electronic Journal of Practices and Technologies, vol. 25, pp. 84-98, 2014.

A. A. Ahamed, R. Ahmed, M. B. Hossain, and M. Billah, “Fabrication and characterization of aluminium-rice husk ash composite prepared by stir casting method,” Rajshahi University Journal of Science and Engineering, vol. 44, pp. 9-18, 2016

S. A. Ali, and B. S. Motgi, A Study on Mechanical Properties of Al7068 Based Metal Matrix Composite Reinforced with Rice Husk Ash (RHA) and Silicon Carbide (SiC). 2021.

Z. Seikh, S. Kunar, R. Haque, S. Haidar, and M. Sekh, “WEDM machining performance of Al based metal matrix composites reinforced with rice husk ash,” Materials Science Forum, vol. 1048, pp. 261-269, 2022.

M. Ariff, A. H. Lin, O. Jung, D. W. Tahir, and S. Sulaiman, “Rice husk ash as pore former and reinforcement on the porosity, microstructure, and tensile strength of aluminum mmc fabricated via the powder metallurgy method,” Powder Metallurgy Method. Crystals, vol. 12, no. 8, 2022.

S. P. Dwivedi, and V. R. Mishra, “Physico-chemical, mechanical and thermal behaviour of Agro-waste RHA-reinforced green emerging composite material,” Arabian Journal for Science and Engineering, vol. 44, no. 9, pp. 8129-8142, 2019.

J. A. K. Gladston, I. Dinaharan, N. M. Sheriff, and J. D. R. Selvam, “Dry sliding wear behavior of AA6061 aluminum alloy composites reinforced rice husk ash particulates produced using compocasting,” Journal of Asian Ceramic Societies vol. 5, no. 2, pp. 127-135, 2017.

S. Mahalingam, and A. S. Babu, “Characterization of 3-aminopropyltriethoxysilane treated stacked silicate nanoclay and red Matta-RHA biosilica woven ramie fibre epoxy composite,” Silicon, vol. 14, no. 13, pp. 8129-8139, 2022.

O. E. Ezenkwa, A. Hassan, and S. A. Samsudin, “Mechanical properties of rice husk and rice husk ash filled maleated polymers compatibilized polypropylene composites,” Journal of Applied Polymer Science, vol. 139, no. 9, p. 51702, 2022.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.