Wear behavior of in-situ oxide dispersion strengthened Fe-8Ni alloy with Zr additions

DOI:

https://doi.org/10.55713/jmmm.v33i1.1568คำสำคัญ:

Oxide dispersion strengthened alloys, Wear test, Wear behavior, Second precipitatesบทคัดย่อ

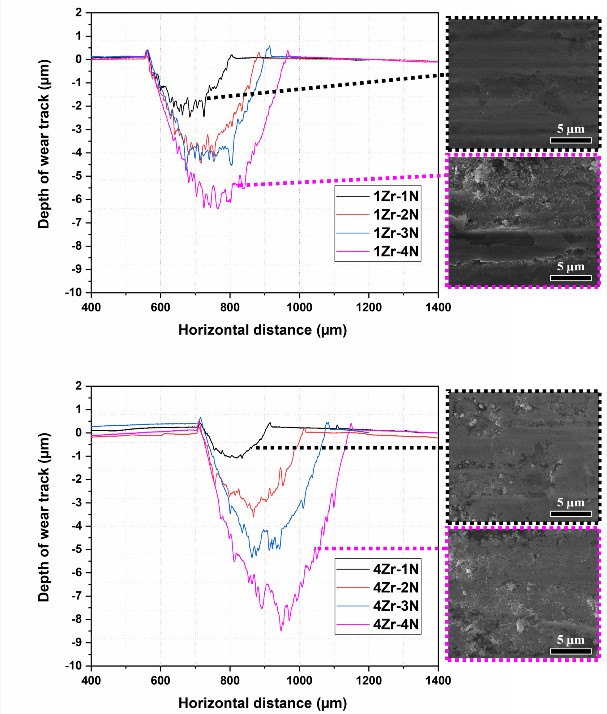

In this study, in-situ oxide dispersion strengthened (ODS) Fe91Ni8Zr1 and Fe88Ni8Zr4 alloys were produced by combination of high energy mechanical alloying (HEMA) and high temperature equal channel angular extrusion (HT-ECAE). The wear behaviors of the consolidated samples were investigated under different loads from 1 N to 4 N by reciprocating wear tests at room temperature. The Scanning electron microscopy (SEM) was used to examine the wear tracks to analyze the wear characteristics as a function of applied loads. The relative comparison of the wear results showed that under the lower loads of 1 N and 2 N, Fe88Ni8Zr4 alloy has lower wear rate than Fe91Ni8Zr1 alloy whereas under the higher loads of 3 N and 4 N, it is vice versa. Additionally, the friction coefficient of Fe91Ni8Zr1 alloy was found to be lower than that of Fe88Ni8Zr4 alloy under all the applied loads. The results were comparatively discussed with respect to microstructural features of 1 at% Zr and 4 at% Zr containing ODS alloys produced by HEMA followed by ECAE. The obtained results of ODS alloys with different grain size, precipitate size, and number density of the precipitates, may disclose a new sight for using such alloys in wear applications just as cutting tools, turbine blades, and discs.

Downloads

เอกสารอ้างอิง

S. Ukai, and M. Fujiwara, "Perspective of ODS alloys application in nuclear environments," Journal of Nuclear Materials, vol. 307, pp. 749-757, 2002.

D. A. McClintock, M. A. Sokolov, D. T. Hoelzer, and R. K. Nanstad, "Mechanical properties of irradiated ODS-EUROFER and nanocluster strengthened 14YWT," Journal of Nuclear Materials, vol. 392, no. 2, pp. 353-359, 2009.

H. Xu, Z. Lu, C. Jia, D. Feng, and C. Liu, "Influence of mechanical alloying time on morphology and properties of 15Cr-ODS steel powders," High Temperature Materials and Processes, vol. 35, no. 5, pp. 473-477, 2016.

H. Xu, Z. Lu, C. Jia, H. Gao, and C. Liu, "Microstructure and mechanical property of 12Cr oxide dispersion strengthened steel," High Temperature Materials and Processes, vol. 35, no. 3, pp. 321-325, 2016.

W. Li, H. Xu, X. Sha, J. Meng, and Z. Wang, "Microstructure and mechanical properties of 14Cr-ODS steels with Zr addition," High Temperature Materials and Processes, vol. 38, no. 2019, pp. 404-410, 2019.

C. Suryanarayana, "Mechanical alloying and milling," Progress in materials science, vol. 46, no. 1-2, pp. 1-184, 2001.

H. Kotan, and K. A. Darling, "Isothermal annealing of a thermally stabilized Fe-based ferritic alloy," Journal of Materials Engineering and Performance, vol. 24, no. 9, pp. 3271-3276, 2015.

G. POLAT, A. B. Batibay, and H. Kotan, "Understanding microstructural evolution and hardness of nanostructured Fe89. 5Ni8Zr2. 5 alloy produced by mechanical alloying and pressureless sintering," Engineering Science and Technology, an International Journal, vol. 23, no. 5, pp. 1279-1284, 2020.

D. J. Barton, C. Kale, B. C. Hornbuckle, K. A. Darling, K. N. Solanki, and G. B. Thompson, "Microstructure and dynamic strain aging behavior in oxide dispersion strengthened 91Fe-8Ni-1Zr (at%) alloy," Materials Science and Engineering: A, vol. 725, pp. 503-509, 2018.

K. A Darling, M. Kapoor, H. Kotan, B. C. Hornbuckle, S. D. Walck, G. B. Thompson, M. A. Tschopp, and L. J. Kecskes, "Structure and mechanical properties of Fe–Ni–Zr oxide-dispersion-strengthened (ODS) alloys," Journal of Nuclear Materials, vol. 467, pp. 205-213, 2015.

H. Kotan, K. A. Darling, and T. Luckenbaugh, "High temperature mechanical properties and microstructures of thermally stabilized Fe-based alloys synthesized by mechanical alloying followed by hot extrusion," Metals and Materials International, pp. 1-8, 2019.

M. Hillert, "On the theory of normal and abnormal grain growth," Acta metallurgica, vol. 13, no. 3, pp. 227-238, 1965.

T. Gladman, "On the theory of the effect of precipitate particles on grain growth in metals," Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, vol. 294, no. 1438, pp. 298-309, 1966.

F. J. Humphreys, and M. Hatherly, Recrystallization and related annealing phenomena. Elsevier, 2012.

N. Nabiran, S. Weber, and W. Theisen, "Ferritic stainless steels for high-temperature applications: stabilization of the microstructure by solid state precipitation of MX carbonitrides," High Temperature Materials and Processes, vol. 32, no. 6, pp. 563-572, 2013.

W. A. Story, D. J. Barton, B. C. Hornbuckle, K. A. Darling, G. B. Thompson, and L. N. Brewer, "Laser assisted cold spray of Fe–Ni–Zr oxide dispersion strengthened steel," Materialia, vol. 3, pp. 239-242, 2018.

H. Kotan, K. A. Darling, M. Saber, C. C. Koch, and R. O. Scattergood, "Effect of zirconium on grain growth and mechanical properties of a ball-milled nanocrystalline FeNi alloy," Journal of alloys and compounds, vol. 551, pp. 621-629, 2013.

S. Karak, C. Vishnu, Z. Witczak, W. Lojkowski, J. D. Majumdar, and I. Manna, "Studies on wear behavior of nano-Y2O3 dispersed ferritic steel developed by mechanical alloying and hot isostatic pressing," Wear, vol. 270, no. 1-2, pp. 5-11, 2010.

R. Autay, M. Kchaou, and F. Dammak, "Friction and wear behavior of steels under different reciprocating sliding conditions," Tribology Transactions, vol. 55, no. 5, pp. 590-598, 2012.

A. Jourani, and S. Bouvier, "Friction and wear mechanisms of 316L stainless steel in dry sliding contact: Effect of abrasive particle size," Tribology Transactions, vol. 58, no. 1, pp. 131-139, 2015.

H. Kotan, "Thermal stabilization and mechanical properties of nanocrystalline iron-nickel-zirconium alloys," North Carolina State University, 2013.

J. Macheret, G. Korth, T. Lillo, A. Watkins, D. Herling, and M. Smith, "Equal channel angular extrusion," Idaho National Engineering and Environmental Laboratory Idaho Falls, Idaho, vol. 83415, p. 1, 1999.

J. Archard, "Contact and rubbing of flat surfaces," Journal of Applied Physics, vol. 24, no. 8, pp. 981-988, 1953.

Y. Z. Chen, K. Wang, G. B. Shan, A. V. Ceguerra, L. K. Huang, H. Dong, L. F. Cao, S. P. Ringer, and F. Liu, "Grain size stabilization of mechanically alloyed nanocrystalline Fe-Zr alloys by forming highly dispersed coherent Fe-Zr-O nanoclusters," Acta Materialia, vol. 158, pp. 340-353, 2018.

T. Torgerson, S. Mantri, R. Banerjee, and T. Scharf, "Room and elevated temperature sliding wear behavior and mechanisms of additively manufactured novel precipitation strengthened metallic composites," Wear, vol. 426, pp. 942-951, 2019.

G. Pantazopoulos, T. Papazoglou, P. Psyllaki, G. Sfantos, S. Antoniou, K. Papadimitriou, and J. Sideris, "Sliding wear behaviour of a liquid nitrocarburised precipitation-hardening (PH) stainless steel," Surface and Coatings Technology, vol. 187, no. 1, pp. 77-85, 2004.

M.-H. Chuang, M.-H. Tsai, W.-R. Wang, S.-J. Lin, and J.-W. Yeh, "Microstructure and wear behavior of AlxCo1. 5CrFeNi1. 5Tiy high-entropy alloys," Acta Materialia, vol. 59, no. 16, pp. 6308-6317, 2011.

K. M. Asl, A. Masoudi, and F. Khomamizadeh, "The effect of different rare earth elements content on microstructure, mechanical and wear behavior of Mg–Al–Zn alloy," Materials Science and Engineering: A, vol. 527, no. 7-8, pp. 2027-2035, 2010.

A. Martı́n, J. Rodrı́guez, and J. Llorca, "Temperature effects on the wear behavior of particulate reinforced Al-based composites," Wear, vol. 225, pp. 615-620, 1999.

A. M. Hassan, M. Almomani, T. Qasim, and A. Ghaithan, "Effect of processing parameters on friction stir welded aluminum matrix composites wear behavior," Materials and Manufacturing Processes, vol. 27, no. 12, pp. 1419-1423, 2012.

J. Moon, S. Kim, J.-i. Jang, J. Lee, and C. Lee, "Orowan strengthening effect on the nanoindentation hardness of the ferrite matrix in microalloyed steels," Materials Science and Engineering: A, vol. 487, no. 1-2, pp. 552-557, 2008.

W. Zhai, W. Zhou, and S. M. L. Nai, "Grain refinement and strengthening of 316L stainless steel through addition of TiC nanoparticles and selective laser melting," Materials Science and Engineering: A, vol. 832, p. 142460, 2022.

B. Kim, J. C. Jiang, and P. B. Aswath, "Mechanism of wear at extreme load and boundary conditions with ashless anti-wear additives: Analysis of wear surfaces and wear debris," Wear, vol. 270, no. 3-4, pp. 181-194, 2011.

A. Mukhopadhyay, and R. I. Todd, "Relationship between microstructure and abrasive wear resistance of Al2O3–FeAl2O4 nanocomposites produced via solid-state precipitation," Journal of the European Ceramic Society, vol. 31, no. 3, pp. 339-350, 2011.

W. Xi, B. Song, Z. Sun, T. Yu, J. Wang, and Q. Sun, "Effect of various morphology of in situ generated NbC particles on the wear resistance of Fe-based cladding," Ceramics International, 2022.

J. Barnby, "The initiation of ductile failure by fractured carbides in an austenitic stainless steel," Acta Metallurgica, vol. 15, no. 5, pp. 903-909, 1967.

N. Das, P. Sengupta, S. Roychowdhury, G Sharma, P. S. Gawde, A. Arya, V. Kain, U. D. Kulkarni, J. K. Chakravartty, G. K. Dey, "Metallurgical characterizations of Fe–Cr–Ni–Zr base alloys developed for geological disposal of radioactive hulls," Journal of nuclear materials, vol. 420, no. 1-3, pp. 559-574, 2012.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.