Feasibility study of coconut shell biochar production using community-scale biochar kiln

DOI:

https://doi.org/10.55713/jmmm.v33i2.1699คำสำคัญ:

Biochar, Coconut shell, Pyrolysis kiln, Net present value, Multiple response optimizationบทคัดย่อ

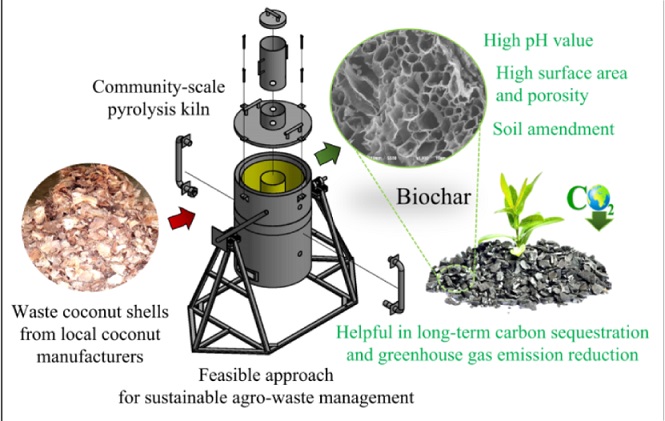

The enormous coconut shell waste from local farmers and manufacturers has caused negative environmental and economic impacts in Thailand. A low-cost, small-scale pyrolysis kiln comprised of a cylindrical tank, gas circulating pipes, a kiln stand, and a manual drum lever was constructed and used to produce biochar from coconut shells in this study. The air intake and holding times for the biochar production process were varied. The biochar yield was 30.67% to 36.22%, or 4.6 kg to 5.4 kg per day per unit. The biochar porosity and fixed carbon content increased as the air intake and holding times were increased. The BET surface areas were 7.54 m²∙g-1 to 63.17 m²∙g-1. The pH values of biochar were alkaline, in the range of 7.34 to 10.24. Therefore, biochar can be used as a soil amendment material. The Net Present Value (NPV), the Internal Rate of Return (IRR), and the payback period are 52,757 THB (1,459.79 USD), 18.71%, 4 years, 10 months, and 27 days, respectively. According to economic analysis, investing in coconut shell biochar production under optimal conditions using the developed kiln is acceptable and can be viewed as a potential approach to providing additional economic benefits for coconut-based enterprises and the Thai community.

Downloads

เอกสารอ้างอิง

M. Shahbandeh, “Global leading producers of coconuts 2020.” Accessed: 29 November, 2022. [Online]. Available: https://www.

statista.com/statistics/1040499/world-coconut-production-by-leading-producers/

Office of Agricultural Economics, “Agricultural production data: Coconut.” Accessed” 29 November, 2022. [Online]. Available: https://www.oae.go.th/view/1/%E0%B8%95%E0%B8%B2%E0%B8%A3%E0%B8%B2%E0%B8%87%E0%B9%81%E0%B8%AA%E0%B8%94%E0%B8%87%E0%B8%A3%E0%B8%B2%E0%B8%A2%E0%B8%A5%E0%B8%B0%E0%B9%80%E0%B8%AD%E0%B8%B5%E0%B8%A2%E0%B8%94%E0%B8%A1%E0%B8%B0%E0%B8%9E%E0%B8%A3%E0%B9%89%E0%B8%B2%E0%B8%A7/TH-TH

P. R. Yaashikaa, P. Senthil Kumar, and S. Varjani, “Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review,” Bioresource Technology, vol. 343, p. 126126, 2022.

L. A. Nunes, M. L. S. Silva, J. Z. Gerber, and R. de A. Kalid, “Waste green coconut shells: Diagnosis of the disposal and applications for use in other products,” Journal of Cleaner Production, vol. 255, p. 120169, 2020.

P. Singh, P. Dubey, K. Younis, and O. Yousuf, “A review on the valorization of coconut shell waste,” Biomass Conversion and Biorefinery, p. 1-11, 2022.

P. Odetola, A. P. Popoola, E. Ajenifuja, and O. Popoola, “Influence of coconut shell powder organic reinforcement on chemical, microstructural and mechanical properties of spark plasma sintered Ti-Ni based metal matrix composite,” Journal of Metals, Materials and Minerals, vol. 30, no. 4, pp. 119-127, 2020.

G. Y. Obeng, D. Y. Amoah, R. Opoku, C. K. K. Sekyere, E. A. Adjei, and E. Mensah, “Coconut wastes as bioresource for sustainable energy: Quantifying wastes, calorific values and emissions in Ghana,” Energies (Basel), vol. 13, no. 9, p. 2178, 2020.

R. Kabir Ahmad, S. Anwar Sulaiman, S. Yusup, S. Sham Dol, M. Inayat, and H. Aminu Umar, “Exploring the potential of coconut shell biomass for charcoal production,” Ain Shams Engineering Journal, vol. 13, no. 1, p. 101499, 2022.

B. Saletnik, G. Zagula, M. Bajcar, M. Tarapatskyy, G. Bobula, and C. Puchalski, “Biochar as a multifunctional component of the environment-a review,” Applied Sciences (Switzerland), vol. 9, no. 6, p. 1139, 2019.

A. Anand, V. Kumar, and P. Kaushal, “Biochar and its twin benefits: Crop residue management and climate change mitigation in India,” Renewable and Sustainable Energy Reviews, vol. 156, p. 111959, 2022.

N. Abeysinghe, K. Jetsrisuparb, K. H. T. Karunarathna, E. P. S. Chandana, S. Suwanree, P. Kasemsiri, P. Chindaprasirt, and J. T. N. Knijnenburg, “Synthesis and phosphate adsorption performance of elephant dung biochar modified with magnesium and iron,” Journal of Metals, Materials and Minerals, vol. 32, no. 1, pp. 124-133, 2022.

M. Maniscalco, G. Infurna, G. Caputo, L. Botta, and N. T. Dintcheva, “Slow pyrolysis as a method for biochar production from carob waste: Process investigation and products’ characterization,” Energies (Basel), vol. 14, no. 24, p. 8457, 2021.

M. Ayaz, D. Feizienė, V. Tilvikienė, K. Akhtar, U. Stulpinaitė, and R. Iqbal, “Biochar role in the sustainability of agriculture and environment,” Sustainability (Switzerland), vol. 13, no. 3, pp. 1-22, 2021.

L. J. Clarke, “Constraining bioavailable polyaromatic hydro-carbons effectively during the production and application of biochar,” Environmental Technology and Innovation, vol. 24, p. 101838, 2021.

S. Joseph. A. L. Cowie, L. V. Zwieten, N. Bolan, A. Budai, W. Buss, M. L. Cayuela, E. R. Graber, J. A. Ippolito, Y. Kuzyakov, Y. Luo, Y. S. Ok, K. N. Palansooriya, J. Shepherd, S. Stephens, Z. Weng, and J. Lehmann, “How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar,” GCB Bioenergy, vol. 13, no. 11, pp. 1731-1764, 2021.

Q. Hu, J. Jung, and D. Chen, “Biochar industry to circular economy,” Science of the Total Environment, vol. 757, p. 143820, 2021.

S. Khawkomol, R. Neamchan, T. Thongsamer, S Vinitnantharat, B. Panpradit, P. Sohsalam, D. Werner and W. Mrozik, “Potential of biochar derived from agricultural residues for sustainable management,” Sustainability (Switzerland), vol. 13, no. 15, p. 8147, 2021.

D. J.-P. Lompo, L. Yé, S. Ouédraogo, S. I. Sori, and H. B. Nacro, “Production and characterization of crop residues derived biochars for soil amendment and carbon sequestration,” Journal of Agricultural Studies, vol. 9, no. 1, p. 130, 2021.

Y. Li, X. Shi, Y. Zhang, J. Xue, X. Chen, Y. Zhang, and T. Ma, “Numerical investigation on the gas and temperature evolutions during the spontaneous combustion of coal in a large-scale furnace,” Fuel, vol. 287, no. 15, p. 119557, 2021.

R. Zou, J. Liu, N. Wang, and H. Jiao, “Combined effects of intake oxygen enrichment, intake pressure and temperature on combustion behavior and emission characteristics of a small-scaled rotary engine,” Applied Thermal Engineering, vol. 207, no. 5, p. 118096, 2022.

G. Venkatesh, K. A. Gopinath, K. S. Reddy, B. S. Reddy, M. Prabhakar, C. Srinivasarao, V. V. Kumari, and V. K. Singh, “Characterization of biochar derived from crop residues for soil amendment, carbon sequestration and energy use,” Sustainability (Switzerland), vol. 14, no. 4, p. 2295, 2022.

K. Wang, N. Peng, G. Lu, and Z. Dang, “Effects of Pyrolysis temperature and holding time on physicochemical properties of Swine-Manure-Derived biochar,” Waste Biomass Valorization, vol. 11, no. 2, pp. 613-624, 2020.

J. Yu, M. Song, and Z. Li, “Optimization of biochar preparation process and carbon sequestration effect of pruned wolfberry branches,” Green Processing and Synthesis, vol. 11, no. 1, pp. 423-434, 2022.

X. Yang, K. Kang, L. Qiu, L. Zhao, and R. Sun, “Effects of carbonization conditions on the yield and fixed carbon content of biochar from pruned apple tree branches,” Renew Energy, vol. 146, pp. 1691-1699, 2020.

T. Rout, D. Pradhan, R. K. Singh, and N. Kumari, “Exhaustive study of products obtained from coconut shell pyrolysis,” Journal of Environmental Chemical Engineering, vol. 4, no. 3, pp. 3696-3705, 2016.

M. H. Samsudin, M. A. Hassan, J. Idris, N. Ramli, M. Zulkhairi, I. Ibrahim, M. R. Othman, A. A. M. Ali, and Y. Shirai, “A one-step self-sustained low temperature carbonization of coconut shell biomass produced a high specific surface area biochar-derived nano-adsorbent,” Waste Management and Research, vol. 37, no. 5, pp. 551-555, 2019.

S. X. Zhao, N. Ta, and X. D. Wang, “Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material,” Energies (Basel), vol. 10, no. 9, p. 1293, 2017.

S. Suman, and S. Gautam, “Pyrolysis of coconut husk biomass: Analysis of its biochar properties,” Energy Sources, Part A: Recovery, Utilization and Environmental Effects, vol. 39, no. 8, pp. 761-767, 2017.

L. K. Palniandy, L. W. Yoon, W. Y. Wong, S. T. Yong, and M. M. Pang, “Application of biochar derived from different types of biomass and treatment methods as a fuel source for direct carbon fuel cells,” Energies (Basel), vol. 12, no. 13, p. 2477, 2019.

A. Ulusal, E. Apaydın Varol, V. J. Bruckman, and B. B. Uzun, “Opportunity for sustainable biomass valorization to produce biochar for improving soil characteristics,” Biomass Conversion and Biorefinery, vol. 11, no. 3, pp. 1041-1051, 2021.

O. Oginni, and K. Singh, “Influence of high carbonization temperatures on microstructural and physicochemical characteristics of herbaceous biomass derived biochars,” Journal of Environmental Chemical Engineering, vol. 8, no. 5, p. 104169, 2020.

M. James, W. Yuan, M. D. Boyette, D. Wang, and A. Kumar, “Characterization of biochar from rice hulls and wood chips produced in a top-lit updraft biomass gasifier,” Transactions of the ASABE, vol. 59, no. 3, pp. 749-756, 2016.

L. Wang, L. Xie, X. Feng, X. Li, H. Ma, G. Han, D. Yang, and J. Zhou, “Optimization process of porous carbon derived from coconut shell: A novel preparation condition and investigation on pore surface roughness,” Diamond and Related Materials, vol. 123, no. 10, p. 108854, 2022.

E. M. C. C. Batista, J. Shultz, T. T. S. Matos, M. R. Fornari, T. M. Ferreira, R. A. de Freitas, and A. S. Mangrich, “Effect of surface and porosity of biochar on water holding capacity aiming indirectly at preservation of the Amazon biome,” Scientific Reports, vol. 8, no. 1, 2018.

M. A. Babatabar, F. Yousefian, M. V. Mousavi, M. Hosseini, and A. Tavasoli, “Pyrolysis of lignocellulosic and algal biomasses in a fixed-bed reactor: A comparative study on the composition and application potential of bioproducts,” International Journal of Energy Research, vol. 46, no. 7, pp. 9836-9850, 2022.

S. D. Menon, K. Sampath, and S. S. Kaarthik, “Feasibility studies of coconut shells biomass for downdraft gasification,” in Materials Today: Proceedings, 2021, vol. 44, pp. 3133-3137., 2021.

D. Castilla-Caballero, J. Barraza-Burgos, S. Gunasekaran, A. Roa-Espinosa, J. Colina-Márquez, F. Machuca-Martínez, A. Hernández-Ramírez, and S. Vázquez-Rodríguez “Experimental data on the production and characterization of biochars derived from coconut-shell wastes obtained from the Colombian Pacific Coast at low temperature pyrolysis,” Data Brief, vol. 28, p. 104855, 2020.

N. Khuenkaeo, and N. Tippayawong, “Production and characterization of bio-oil and biochar from ablative pyrolysis of lignocellulosic biomass residues,” Chemical Engineering Communications, vol. 207, no. 2, pp. 153-160, 2020.

S. K. Das, and G. K. Ghosh, “Soil hydro-physical properties affected by biomass-derived biochar and organic manure: A low-cost technology for managing acidic mountain sandy soils of north eastern region of India,” Biomass Conversion and Biorefinery, 2022.

A. Tomczyk, Z. Sokołowska, and P. Boguta, “Biochar physico-chemical properties: pyrolysis temperature and feedstock kind effects,” Reviews in Environmental Science and Biotechnology, vol. 19, no. 1, pp. 191-215, 2020.

P. Pituya, T. Sriburi, and S. Wijitkosum, “Properties of biochar prepared from acacia wood and coconut shell for soil amendment,” Engineering Journal, vol. 21, no. 3, pp. 63-76, 2017.

T. Kocsis, M. Ringer, and B. Biró, “Characteristics and applications of biochar in soil–plant systems: A short review of benefits and potential drawbacks,” Applied Sciences (Switzerland), vol. 12, no. 8, p. 4051, 2022.

K. Jemal, and A. Yakob, “Role of bio char on the amelioration of soil acidity,” Agrotechnology, vol. 10, no. 212, 2021.

A. Giwa, A. Yusuf, O. Ajumobi, and P. Dzidzienyo, “Pyrolysis of date palm waste to biochar using concentrated solar thermal energy: Economic and sustainability implications,” Waste Management, vol. 93, pp. 14-22, 2019.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.