The high temperature degradation of ferritic stainless steel in solid carbon atmospheres

DOI:

https://doi.org/10.55713/jmmm.v33i1.1574Keywords:

Ferritic stainless steel, AISI430, High temperature, Degradation, Coal fired boilersAbstract

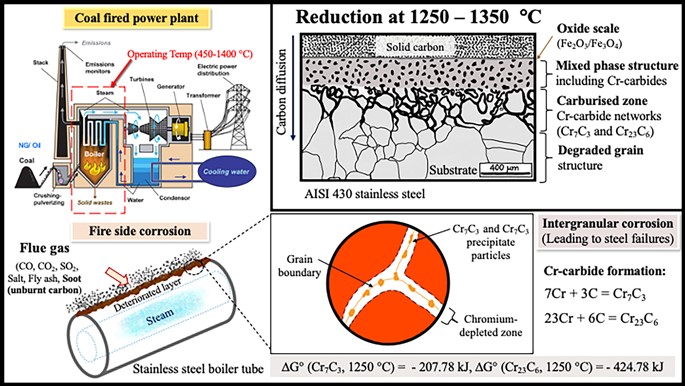

Stainless steel is widely used for many components and parts in coal-fired thermal power plants. AISI 430 ferritic stainless steel (FSS) is one common grade to combat the degradation at high temperatures in coal combustion atmospheres containing flue gas, coal ash, and soot (impure solid carbon particles). However, the effect of the solid carbon particles on the degradation of FSS needs to be clarified. Graphite powder was used to simulate solid carbon atmospheres for investigating the degradation of AISI 430 at high temperatures of 1150℃ to 1350℃ in coal-fired boilers. After the carbothermic reduction, the mass gain of a pre-oxidized sample at 750℃ was approximately 0.0793 mg⸳cm-2 and increased when increasing the reduction temperature. The peak of Fe2O3 and Cr7C3 were detected by X˗ray diffraction (XRD) after the oxidation and reduction test, respectively. Besides, the degree of sensitivity (%DoS) of the samples was measured by double loop electrochemical potentiokinetic reactivation (DL-EPR) technique and increased around 30 times after heating the pre-oxidized sample to 1150℃.

Downloads

References

C. Matthews, Case Studies in Engineering Design. Butterworth-Heinemann, 1998.

G. N. Krishnan, R. Malhotra, J. Perez, M. Hornbostel, K.-H. Lau and A. Sanjurjo, Diffusion Coatings for Corrosion-Resistant Components in Coal Gasification Systems. Pittsburgh, PA: U.S. Department of Energy National Energy Technology Center, 2007.

J. G. Speight, The refinery of the future. Cambridge (Mass.), Kidlington: Gulf Profes-sional Publishing, 2020.

P. Thongyoug, S. Chandra-Ambhorn, and J. Tungtrongpairoj, "The degradation of oxide layer on Cr-containing steels in simulated atmospheres on carbothermic reduction," Materials at High Temperatures, vol. 39, pp. 1-11, 2022.

P. Lacombe, B. Baroux, and G. Beranger, Stainless steels. France: Les Editions de Physique, 1993.

D. T. Llewellyn, Steels: metallurgy and applications. Elsevier, 1998.

W. Bleck, Materials Science of Steel-Textbook for Students at RWTH Aachen. Steel Institute (IEHK) of RWTH Aachen University, 2016.

American Iron and Steel Institute, High-Temperature Characteristics of Stainless Steels. Nickel Development Institute, 2004.

P. Thongyoug, and J. Tungtrongpairoj, "Carbothermic reduction of the waste chromium oxide rods from thermal spray processes," IOP Conference Series: Materials Science and Engineering, vol. 965, pp.12024, 2020.

P. Treewiriyakitja, P. Thongyoug, S. Pokwitidkul and J. Tungtrongpairoj, "The deg-radation of austenitic stainless steel at high temperature in simulated carbon monoxide containing atmosphere of biomass-to-liquid plants," IOP Conference Series: Materials Science and Engineering, vol. 1163, pp. 12022, 2021.

J. Tungtrongpairoj, P. Thongyoug, P. Saranyachot and S. Chandra-Ambhorn, "High temperature degradation of thermal oxides on AISI 304 stainless steels by carbon," Key Engineering Materials, vol. 856, pp. 21-28, 2020.

G. Lothongkum, Stainless steels. Chulalongkorn University Press, 2021.

D. R. Laranjo, "Thermodynamic analysis in the production of chromium carbide from the reduction of chromium oxide with methane-containing gas," Reactions, vol. 183, pp. 120-125, 2018.

B. Leffler, and A. Iversen, "Aqueous corrosion of stainless steel," Corrosion and Degradation of Engineering Materials, vol. 3, pp. 1802-1878, 2010.

D. L. Engelberg, and J. A. Richardson, Intergranular corrosion. in Shreir's Corrosion. Elsevier B.V., 2010.

O. Kubaschewski, C. B. Alcock, Metallurgical thermochemistry 5th ed. UK: Pergamon Oxford, 1979.

K. B. Yoo, Y. He, H. S. Lee, S. Y. Bae, and D. S. Kim, "Study on the microstructural degradation of the boiler tubes for coal-fired power plants," KEPCO Journal on Electric Power and Energy, vol. 4, pp. 25-31, 2018.

F. I. Haider, and M. H. Suryanto, "Carbon diffusion in 304L austenitic stainless steel at 650-750℃ in carburizing environment," International Journal of Recent Technology and Engineering (IJRTE), vol. 7, pp. 76-78, 2019.

H. M. Tawancy, "On the comparative degradation of selected Cr2O3-forming alloys by high-temperature carburization with a case study involving 310 stainless steel," Engineering Failure Analysis, vol. 110, pp. 104402, 2020.

G. F. Vander Voort, Color Metallography. Metals Park, OH: American Society for Metals, 2004.

T. Amadou, H. Sidhom and C. Braham, "Double loop electro-chemical potentiokinetic reactivation test optimization in checking of duplex stainless steel intergranular corrosion susceptibility," Metallurgical and Materials Transactions A, vol. 35, pp. 3499-3513, 2004.

R. Strand, T. L. Christiansen, and M. A. J. Somers, M. Sc. thesis. Technical University of Denmark, 2012.

M. Romedenne, F. Rouillard, D. Hamon, B. Malard, and D. Monceau, "Carburization of austenitic and ferritic stainless steels in liquid sodium: Comparison between experimental observations and simulations," Corrosion Science, vol. 159, p. 108147, 2019.

H. K. D. H. Bhadeshia and R. W. K. Honeycombe, Steels microstructure and properties (Third edition). Butterworth-Heinemann, 2017.

A. G. Andreeva, and A. P. Gulyaev, "Carburization of stainless steels," Metal Science and Heat Treatment of Metals, vol. 2, pp. 137-140, 1960.

S. Kou, and Y. Le, "The effect of quenching on the solidification structure and transformation behavior of stainless steel welds," Metallurgical Transactions A 13, vol. 7, pp. 1141-1152, 1982.

G. Gottstein, Physical foundations of materials science. Springer-Verlag Berlin Heidelberg GmbH, 2004.

A. K. Sinha, Ferrous physical metallurgy. Boston (Mass.): Butterworths, 1989.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.