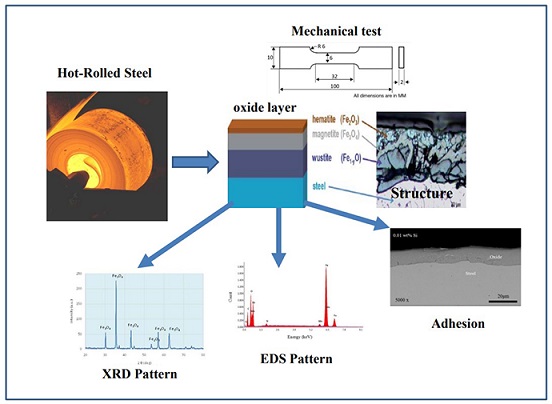

Examination of the adhesion of the scale formed on hot-rolled steel with different silicon content using a tensile test

DOI:

https://doi.org/10.55713/jmmm.v33i1.1577Keywords:

tensile testing machine, oxide scale, scale adhesion, hot-rolled steelAbstract

In the hot-rolling process, steel was subjected to high temperatures which results in the formation of an oxide layer called scale. The oxide scale can be affected to the surface characteristic of the hot-rolled steel product. The scale must be completely removed from the surface of the steel before further processing. This research aimed to examine the adhesion behavior of scale on hot-rolled steel with different silicon contents (0.01, 0.12, 0.18, and 0.29 wt%) using a tensile testing machine with an observation setup. The results showed that the scale thickness decreased with increasing silicon content in the range of 9 µm to 12 µm. The scales were composed of hematite and magnetite. The results of the tensile test showed that the strain initiating the first spallation and the mechanical adhesion energy tend to increase with increasing silicon content. However, it decreased by 0.29 wt% Si hot-rolled steel. This result indicates that scale was difficult to remove after the hot rolling process for higher Si-containing steel.

Downloads

References

X. J. Liu, Y. Q. He, G. M. Cao, T. Jia, T. Z. Wu, and Z. Y. Liu, “Effect of Si content and temperature on oxidation resistance of Fe-Si alloys,” Journal of Iron and Steel Research International, vol. 22, no. 3, pp. 238-244, 2015.

J. Eklund, B. Jönsson, A. Persdotter, J. Liske, J. E. Svensson, and T. Jonsson,“The influence of silicon on the corrosion properties of FeCrAl model alloys in oxidizing environments at 600℃,” Corrosion Science, vol. 144, pp. 266-276, 2018.

Y. L. Yang, C. H. Yang, S. N. Lin, C. H. Chen, and W. T. Tsai, “Effects of Si and its content on the scale formation on hot-rolled steel strips,” Materials Chemistry and Physics, vol. 112, no. 2, pp. 566-571, 2008.

D. Genève, D. Rouxel, P. Pigeat, and M. Confente, “Descaling ability of low-alloy steel wires depending on composition and rolling process.” Corrosion Science, vol. 52, no. 4, pp. 1155-1166, 2010.

Q. Yuan, G. Xu, M. X. Zhou, and B. He, “New insights into the effects of silicon content on the oxidation process in silicon-containing steels,” International Journal of Minerals, Metallurgy, and Materials, vol. 23, no. 9, pp. 1048-1055, 2016.

L. Suárez, P. Rodríguez-Calvillo, Y. Houbaert, and R. Colás, “Oxidation of ultra low carbon and silicon bearing steels,” Corrosion Science, vol. 52, no. 6, pp. 2044-2049, 2010.

H. Utsunomiya, K. Hara, R. Matsumoto, and A. Azushima, “Formation mechanism of surface scale defects in hot rolling process,” CIRP Annals, vol. 63, no. 1, pp. 261-264, 2014.

M. Z. G. Shao, “Characterization and properties of oxide scales on hot-rolled strips,” Materials Science and Engineering A, vol. 452-453, pp. 189-193, 2007.

R. Y. Chen, and W. Y. D. Yuen, “Oxidation of low-carbon, low-silicon mild steel at 450-900℃ under conditions relevant to hot-strip processing,” Oxidation of Metals, vol. 57, no.1/2, pp. 53-79, 2002.

S. Liu, D. Tang, H. Wu, and L. Wang, “Oxide scales characterization of micro-alloyed steel at high temperature,” Journal of Materials Processing Technology, vol. 213, no. 7, pp. 1068-1075, 2013.

R. Y. Chen, and W. Y. D. Yuen, “Examination of oxide scales of hot rolled steel products,” Iron and Steel Institute of Japan International, vol. 45, 1, pp. 52-59, 2005.

P. Sarrazin, A. Galerie, and J. Fouletier, Mechanisms of high temperature corrosion: a kinetic approach. Materials Science Foundations, Trans Tech Publications, Stafa-Zürich, Switzerland, 2008.

M. J. L. Gines, G. J. Benitez, T. Perez, E. Merli, M. A. Firpo, and W. Egli, “Study of the picklability of 1.8 mm hot-rolled steel strip in hydrochloric acid,” Latin American Applied Research, vol. 32, pp. 281-288, 2002.

Z. Y. Jiang, A. K. Tieu, W. H. Sun, J. N. Tang, and D. B. Wei, “Characterisation of thin oxide scale and its surface roughness in hot metal rolling,” Materials Science and Engineering A, vol. 435-436, pp. 434-438, 2006.

L. Suárez, R. Petrov, L. Kestens, M. Lamberigts, and Y. Houbaert, “Texture evolution of tertiary oxide scale during steel plate finishing hot rolling simulation tests,” Materials Science Forum, vol. 550, pp. 557-562, 2007.

S. Chandra-ambhorn, and K. Ngamkham, “High temperature oxidation of micro-alloyed steel and its scale adhesion,” Oxidation of Metals, vol. 88, pp. 291-300, 2017.

S. Chandra-ambhorn, T. Phadungwong, and K. Sirivedin, “Effects of carbon and coiling temperature on the adhesion of thermal oxide scales to hot-rolled carbon steels,” Corrosion Science, vol. 115, pp. 30-40, 2017.

S. Chandra-ambhorn, T. Nilsonthi, Y. Wouters, and A. Galerie, “Oxidation of simulated recycled steels with 0.23 and 1.03 wt% Si in Ar–20% H2O at 900°C,” Corrosion Science, vol. 87, pp. 101-110, 2014.

S. Chandra-ambhorn, A. Jutilarptavorn, and T. Rojhirunsakool, “High temperature oxidation of irons without and with 0.06 wt% Sn in dry and humidified oxygen,” Corrosion Science, vol. 148, pp. 355-365, 2019.

S. Chandra-ambhorn, K. Ngamkham, and N. Jiratthanakul, “Effects of process parameters on mechanical adhesion of thermal oxide scales on hot-rolled low carbon steels,” Oxidation of Metals, vol. 80, 1, pp. 61-72, 2013.

Q. Yuan, G. Xu, M. Zhou, and B. He, “The effect of the Si content on the morphology and amount of Fe2SiO4 in low carbon steels,” Metals, vol. 6, no. 4, pp. 94, 2016.

Y. Yu, C. Wang, L. Wang, J. Chen, Y. J. Hui, and C. K. Sun, “Combination effect of Si and P on tertiary scale characteristic of hot rolled strip,” Journal of Iron and Steel Research International, vol. 22, no. 3, pp. 232-237, 2015.

A. Chattopadhyay, and T. Chanda, “Role of silicon on oxide morphology and pickling behaviour of automotive steels,” Scripta Materialia, vol. 58, no. 10, pp. 882-885, 2008.

M. Zhang, and G. Shao, “Characterization and properties of oxide scales on hot-rolled strips,” Materials Science and Engineering A, vol. 452-453, pp. 189-193, 2007.

T. Nilsonthi, J Tungtrongpairoj, S. Chandra-ambhorn, Y. Wouters, and A. Galerie, “Effect of silicon on formation and mechanical adhesion of thermal oxide scale grown on low carbon steels in a hot-rolling line,” Steel Research International, pp. 987-990, 2012.

T. Nishimoto, K. Honda, Y. Kondo, and K. Uemura, “Effects of Si content on the oxidation behavior of Fe-Si alloys in air,” Materials Science Forum, vol. 696, pp. 126-131, 2011.

E. Ahtoy, M. Picard, G. Leprince, A. Galerie, Y. Wouters, X. Wang, and A. Atkinson, “Time and temperature dependence of the adhesion of oxide scales formed on phosphorus-containing steels during short term oxidation,” Materials Chemistry and Physics, vol. 148, no. 3, pp. 1157-1162, 2014.

J. Liu, and G. Jiang, “Use of laboratory indentation tests to study the surface crack propagation caused by various indenters,” Engineering Fracture Mechanics, vol. 241, pp. 407-421, 2021.

M. M. Islam, S. I. Shakil, N. M. Shaheen, P. Bayati, and M. Haghshenas, “An overview of microscale indentation fatigue: Composites, thin films, coatings, and ceramics,” Micron, vol. 148, pp. 103-110, 2021.

K. Ngamkham, S. Niltawach, and S. Chandra-Ambhorn, “Development of tensile test to investigate mechanical adhesion of thermal oxide scales on hot-rolled steel strips produced using different finishing temperatures,” Key Engineering Materials, vol. 462, pp. 407-412, 2011.

G. Bamba, Y. Wouters, A. Galerie, F. Charlot, and A. Dellali, “Thermal oxidation kinetics and oxide scale adhesion of Fe–15Cr alloys as a function of their silicon content,” Acta Materialia, vol. 54, no. 15, pp. 3917-3922, 2006.

S. Vongsilathai, P. Thapanathitikul, K. Ngamkham, and T. Rojhirunsakool, “Effects of titanium and niobium on micro-structure and mechanical adhesion of thermal oxide scales on hot-rolled low carbon steel,” Suranaree Journal of Science & Technology, vol. 26, no. 11, pp. 84-92, 2019.

S. Chandra-Ambhorn, F. Roussel-Dherbey, F. Toscan, Y. Wouters, A. Galerie, and M. Dupeux, “Determination of mechanical adhesion energy of thermal oxide scales on AISI 430Ti alloy using tensile test,” Materials Science and Technology, vol. 23, no. 4, pp. 497-501, 2007.

H. E. Evans, “Stress effects in high temperature oxidation of metals,” International Materials Reviews, vol. 40, no. 1, pp. 1-40, 1995.

H. E. Evans, “Predicting oxide spallation from sulphur-contaminated oxide/metal interfaces,” Oxidation of Metals, vol. 79, no. 1, pp. 3-14, 2013.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.