Fabrication and characterizations of high density Si\(_{3}\)N\(_{4}\) - ZrO\(_{2}\) ceramics

DOI:

https://doi.org/10.55713/jmmm.v33i3.1621Keywords:

Silicon nitride, Zirconia, Pressureless sintering, Mechanical propertiesAbstract

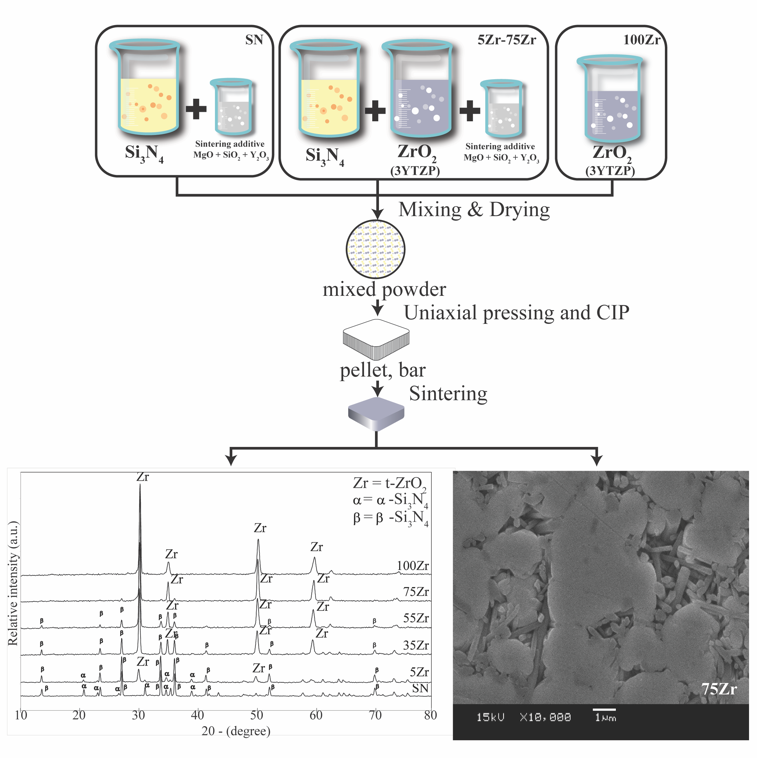

Silicon nitride and zirconia were mixed with SiO2, MgO, Y2O3 as sintering additives and pressureless sintered at 1650℃ in N2 atmosphere for 2 h. The XRD results showed a-Si3N4 was partially transformed to b-Si3N4 with 3:3:5 weight ratio of SiO2 : MgO : Y2O3. However, at 5 wt% of ZrO2 addition promoted phase transformation of a-Si3N4 to b-Si3N4 while 35 wt% of ZrO2 completely transformed to b-Si3N4 phase. Si3N4 has a lower density than ZrO2, bulk density of samples increases in correlation with the amount of ZrO2. Because there was no difference in hardness and flexural strength between sintered Si3N4 samples with hardness of 13.41 GPa and 648.13 MPa along with increasing ZrO2 variation up to 55 wt%. Furthermore, with 75 wt% ZrO2, the hardness was reduced to 10.57 GPa and the flexural strength decreased to 208.16 MPa. SEM images of Si3N4 samples demonstrated the dense microstructure and 5 wt% ZrO2 showed homogeneous ZrO2 distributed among the Si3N4 grains. As a result, the hexagonal rod-like form of b-Si3N4 is clearly visible in 75 wt% ZrO2. Therefore, Si3N4 with ZrO2 can be sintered with the homogeneous microstructure of the a-Si3N4 to b-Si3N4 transformation and tolerable mechanical properties vary with ZrO2 content.

Downloads

References

Z. Krstic, and V. D. Krstic, "Silicon nitride: the engineering material of the future," Journal of Materials Science, vol. 47, pp. 535-552, 2012.

F. L. Riley, "Silicon nitride and related materials," Journal of the American Ceramic Society, vol. 83, pp. 245-265, 2000.

C. Greskovich, and J. H. Rosolowski, "Sintering of covalent solids," Journal of the American Ceramic Society, vol. 59, pp. 336-343, 1976.

G. G. Deeley, J. M. Herbert, and N. C. Moore, "Dense silicon nitride," Powder Metallurgy, vol. 4, pp. 145-151, 1961.

M. Mitomo, "Pressure sintering of Si3N4," Journal of Materials Science, vol. 11, pp. 1103-1107, 1976.

T. Wasanapiarnpong, S. Wada, M. Imai, and T. Yano, "Lower temperature pressureless sintering of Si3N4 ceramics using SiO2-MgO-Y2O3 additives without packing powder," Journal of The Ceramic Society of Japan, vol. 114, pp. 733-738, 2006.

A. Leriche, F. Cambier, and H. Reveron, "Zirconia ceramics, structure and properties," Encyclopedia of Materials: Technical Ceramics and Glasses, vol. 2, pp. 93-104, 2021.

R. H. J. Hannink, P. M. Kelly, and B. C. Muddle, "Transformation toughening in zirconia containing ceramics," Journal of the American Ceramic Society, vol. 83, pp. 461-487, 2000.

S. H. Ahmad, S. M. Rafiaei, S. Ghadami, and K. A. Nekouee, "Densification and mechanical properties of spark plasma sintered Si3N4/ZrO2 nanocomposites," Journal of Alloys and Compounds, vol. 776, pp. 798-806, 2019.

S. Kuang, M. J. Hoffmann, H. L. Lukas, and G. Petzow, "Experimental study and thermodynamic calculation of MgO-Y2O3-SiO2 system," Key Engineering Materials, vol. 89-91, pp. 399-404, 1994.

H. Hyuga, K. Yoshida, N. Kondo, H. Kita, J. Sugai, H. Okano, and J. Tsuchida, "Nitridation enhancing effect of ZrO2 on silicon powder," Materials Letters, vol. 62, pp. 3475-3477, 2008.

I. Hussainova, N. Voltsihhin, E. Cura, and S. P. Hannula, "Densification and characterization of spark plasma sintered ZrC–ZrO2 composites," Materials Science and Engineering: A, vol. 597, pp. 75-81, 2014.

P. G. Hua, L. X. Guo, L. Min, L. Z. Hua, L. Qian, and L. W. Ian, "Spark plasma sintered high hardness α/β Si3N4 composites with MgSiN2 as additives," Scripta Materialia, vol. 61, pp. 347-350, 2009.

P. Reis, J. P. Davim, X. Xu, and J. M. F. Ferriera, "Tribological behaviour of colloidally processed sialon ceramics sliding against steel under dry conditions," Tribology Letters, vol. 18, pp. 295-301, 2005.

K. Jeong, J. Tatami, M. Iijima, and T. Nishimura, "Spark plasma sintering of silicon nitride using nanocomposite particles," Advanced Powder Technology, vol. 28, pp. 37-42, 2017.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.