Investigated the ion energy and the microstructure properties of tetrahedral amorphous carbon film produced by pulsed filtered cathodic vacuum arc combined with plasma biasing technique

DOI:

https://doi.org/10.55713/jmmm.v34i4.2168Keywords:

Pulsed filtered cathodic vacuum arc, Plasma biasing technique, Average ion energy, Microstructure, ta-C filmAbstract

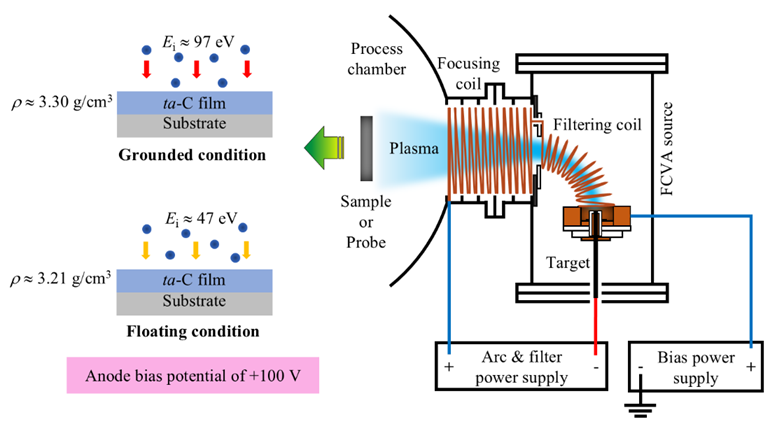

The purpose of this work is to demonstrate that operations using the plasma biasing technique in pulsed filtered cathodic vacuum arc (PFCVA) enable an energy-enhanced in deposition process for the high quality of tetrahedral amorphous carbon (ta-C) thin films (high sp3 content, denser, and very low surface roughness). The effect of anode bias potential on the energy distribution function of C+ ions, including the topography, microstructure, chemical state, and density of ta-C films, was systematically investigated. It was found that the plasma biasing technique can increase the average energy of C+ ions, but nevertheless, the ion flux and ion density decreased. The ion energetically enhanced deposition during PFCVA facilitates the densification of the films up to 3.30 g∙cm‒3 for substrate with the grounded substrate condition, and up to 3.22 g∙cm‒3 for substrate with the floating substrate condition. In addition, the films surface roughness and sp3 content significantly depend on the average ion energy.

Downloads

References

C. Li, L. Huang, and J. Yuan, “Effect of sp3 content on adhesion and tribological properties of non-hydrogenated DLC films,” Materials (Basel), vol. 13, no. 8, 2020. DOI: https://doi.org/10.3390/ma13081911

A. C. Ferrari, and J. Robertson, “Interpretation of Raman spectra of disordered and amorphous carbon,” Physical Review B, vol. 61, no. 20, pp. 95-107, 2000. DOI: https://doi.org/10.1103/PhysRevB.61.14095

K. Bewilogua, and D. Hofmann, “History of diamond-like carbon films - From first experiments to worldwide applications,” Surface and Coatings Technology, vol. 242, pp. 214-225, 2014. DOI: https://doi.org/10.1016/j.surfcoat.2014.01.031

L. Wang, Y. Liu, H. Chen, and M. Wang, “Modification methods of diamond like carbon coating and the performance in machining applications: A review,” Coatings, vol. 12, no. 224, 2022. DOI: https://doi.org/10.3390/coatings12020224

Y. Wang, Y. Ye, H. Li, L. Ji, J. Chen, and H. Zhou, “A magnetron sputtering technique to prepare a-C:H films: Effect of substrate bias,” Applied Surface Science, vol. 257, no. 6, pp. 1990-1995, 2011. DOI: https://doi.org/10.1016/j.apsusc.2010.09.040

T. Brzezinka, J. Rao, J. M. DePaiva, J. Kohlscheen, G. Fox-Rabinovich, S. C. Veldhuis, and J. L. Endrino, “DLC and DLC-WS2 coatings for machining of aluminium alloys,” Coatings, vol. 9, no. 3, p. 192, 2019. DOI: https://doi.org/10.3390/coatings9030192

S. N. Grigoriev, M. A. Volosova, A. A. Vereschaka, N. Sitnikov, F. O. Milovich, J. I. Bublikov, S. V. Fyodorov, and A. E. Seleznov, “Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate,” Ceramics International, vol. 46, no. 11, pp. 18241-18255, 2020. DOI: https://doi.org/10.1016/j.ceramint.2020.04.147

D. Nakajima, H. Kuwabara, S. Annaka, S. Fujii, Y. Tanaka, and K. Hirakuri, “Diamond-like carbon coating for effective electrical insulation of Cu and Al wires,” Diamond and Related Materials, vol. 103, no. 103, p. 107731, 2020. DOI: https://doi.org/10.1016/j.diamond.2020.107731

C. Casiraghi, J. Robertson, and A. C. Ferrari, “Diamond-like carbon for data and beer storage,” Materials Today, vol. 10, no. 1-2, pp. 44-53, 2007. DOI: https://doi.org/10.1016/S1369-7021(06)71791-6

J. Robertson, “Diamond-like amorphous carbon”, Materials Science and Engineering, vol. 37, pp. 129-281, 2002. DOI: https://doi.org/10.1016/S0927-796X(02)00005-0

A. C. Ferrari, “Diamond-like carbon for magnetic storage disks,” Surface and Coatings Technology, vol. 180-181, pp. 190-206, 2004. DOI: https://doi.org/10.1016/S0257-8972(03)01189-7

X. Li, S. Xu, P. Ke, and A. Wang, “Thickness dependence of properties and structure of ultrathin tetrahedral amorphous carbon films: A molecular dynamics simulation,” Surface and Coatings Technology, vol. 258, pp. 938-942, 2014. DOI: https://doi.org/10.1016/j.surfcoat.2014.07.054

J. Robertson, “Requirements of ultrathin carbon coatings for magnetic storage technology,” Tribology International, vol. 36, pp. 405-415, 2003. DOI: https://doi.org/10.1016/S0301-679X(02)00216-5

C. Casiraghi, A. C. Ferrari, J. Robertson, R. C. Ohr, M. v. Gradowski, D. Schneider, and H. Hilgers, “Ultra-thin carbon layer for high density magnetic storage devices,” Diamond and Related Materials, vol. 13, no. 4, pp. 1480-1485, 2004. DOI: https://doi.org/10.1016/j.diamond.2003.12.018

M. G. Beghi, A. C. Ferrari, K. B. K. Teo, J. Robertson, C. E. Bottani, A. L. Bassi, and B. K. Tanner, “Bonding and mechanical properties of ultrathin diamond-like carbon films,” Applied Physics Letters, vol. 81 no. 20, pp. 3804-3806, 2002. DOI: https://doi.org/10.1063/1.1510179

P. S. Goohpattader, N. Dwivedi, E. Rismani-Yazdi, N. Satyanarayana, R. J. Yeo, S. Kundu, and C. S. Bhatia, “Probing the role of C+ ion energy, thickness and graded structure on the functional and microstructural characteristics of ultrathin carbon films (< 2 nm),” Tribology International, vol. 81, pp.73-88, 2015. DOI: https://doi.org/10.1016/j.triboint.2014.08.001

S. Xu, B. K. Tay, H. S. Tan, L. Zhong, Y. Tu, S. R. P. Silva, and W. I. Milne, “Properties of carbon ion deposited tetrahedral amorphous carbon films as a function of ion energy,” Journal of Applied Physics, vol. 79, no. 9, pp. 7234-7240, 1996. DOI: https://doi.org/10.1063/1.361440

M. Chhowalla, J. Robertson, C. W. Chen, S. R. P. Silva, C. A.Davis, G. Amaratunga, and W. I. Milne, “Influence of ion energyand substrate temperature on the optical and electronic properties of tetrahedral amorphous carbon (ta-C) films,” Journal of Applied Physics, vol. 81, pp. 139-145, 1997. DOI: https://doi.org/10.1063/1.364000

E. Martínez, J. L. Andújar, M. C. Polo, J. Esteve, J. Robertson, and W. I. Milne, “Study of the mechanical properties of tetrahedral amorphous carbon films by nanoindentation and nanowear measurements,” Diamond and Related Materials., vol. 10, pp. 145-152, 2001. DOI: https://doi.org/10.1016/S0925-9635(00)00461-1

J. Wei, H. Li, L. Liu, P. Guo, P. Ke, and A. Wang, “Enhanced tribological and corrosion properties of multilayer ta-C films via alternating sp3 content,” Surface and Coatings Technology, vol. 374, pp. 317-326, 2019. DOI: https://doi.org/10.1016/j.surfcoat.2019.05.087

A. LiBassi, A. C. Ferrari, V. Stolojan, B. K. Tanner, J. Robertson, and L. M. Brown, “Density, sp3 content and internal layering of DLC films by X-ray reflectivity and electron energy loss spectroscopy,” Diamond and Related Materials, vol. 9, pp. 771-776, 2000. DOI: https://doi.org/10.1016/S0925-9635(99)00233-2

C. Casiraghi, A. C. Ferrari, R. Ohr, D. Chu, and J. Robertson, “Surface properties of ultra-thin tetrahedral amorphous carbon films for magnetic storage technology,” Diamond and Related Materials vol. 13, pp. 1416-1421, 2004. DOI: https://doi.org/10.1016/j.diamond.2003.10.086

J. Zhu, J. Han, X. Han, H. I. Schlaberg, and J. Wang, “sp3-rich deposition conditions and growth mechanism of tetrahedral amorphous carbon films deposited using filtered arc,” Journal of Applied Physics, vol. 104, no. 1, pp. 013512-013519, 2008. DOI: https://doi.org/10.1063/1.2951588

N. Soin, S. S. Roy, S. C. Ray, P. Lemoine, Md. A. Rahman, P. D. Maguire, S. K. Mitra, and J. A. McLaughlin, “Thickness dependent electronic structure of ultra-thin tetrahedral amorphous carbon (ta-C) films,” Thin Solid Films, vol. 520, no. 7, pp. 2909-2915, 2007. DOI: https://doi.org/10.1016/j.tsf.2011.12.039

R. McCann, S. S. Roy, P. Papakonstantinou, G. Abbas, and J. A. McLaughlin, “The effect of thickness and arc current on the

structural properties of FCVA synthesised ta-C and ta-C:N films,” Diamond and Related Materials, vol. 14, pp. 983-988, 2005 DOI: https://doi.org/10.1016/j.diamond.2004.12.037

J. Pelletier, “Substrate biasing during plasma processing: interest, methods and limitations,” in Advanced technologies based on wave and beam generated plasmas, vol. 67, H. Schlüter, and A. Shivarova, Eds., Dordrecht, Netherlands: Springer, 1999, pp. 137-148. DOI: https://doi.org/10.1007/978-94-017-0633-9_7

J. Sarkar, “Sputtering targets and sputtered films for the micro-electronic industry,” in Sputtering Materials for VLSI and Thin Film Devices, J. Sarkar, Ed., Norwich, NY, USA: William Andrew, 2014, ch. 1, pp. 1-94. DOI: https://doi.org/10.1016/B978-0-8155-1593-7.00001-1

N. Dwivedi, A. K. Ott, K. Sasikumar, C. Dou, R. Yeo, B. Narayanan, U. Sassi, D. D. Fazio, G. Soavi, T. Dutta, O. Balci, S. Shinde, J. Zhang, A. K. Katiyar, P. S. Keatley, A. K. Srivastava, S. K. R. S. Sankaranarayanan, A. C. Ferrari, and C. S. Bhatia, “Graphene overcoats for ultra-high storage density magnetic media,” Nature Communications, vol. 12, no. 1, pp. 1-13, 2021. DOI: https://doi.org/10.1038/s41467-021-22687-y

D. Weller, G. Parker, O. Mosendz, A. Lyberatos, D. Mitin, N. Schmidt, and M. Albrecht, “Review Article: FePt heat assisted magnetic recording media,” Journal of Vacuum Science and Technology B: Nanotechnology and Microelectronics, vol. 34, no. 6, p. 060801, 2016. DOI: https://doi.org/10.1116/1.4965980

N. Dwivedi, E. Rismani-Yazdi, R. Yeo, R. S. G. Pattader, N. Satyanarayana, N. Srinivasan, B. Druz, S. Tripathy, and C. S. Bhatia, “Probing the role of an atomically thin SiNx interlayer on the structure of ultrathin carbon films,” Scientific Report, vol. 4, no. 1, p. 5021, 2014. DOI: https://doi.org/10.1038/srep05021

Y. Chen, H. Z. Yang, S. H. Leong, K. M. Cher, J. Hu, P. Sethi, and W. S. Lew, “Erasure temperature measurements of heat assisted magnetic recording media,” Journal of Applied Physics, vol. 117, no. 17, 2015. DOI: https://doi.org/10.1063/1.4914362

S. N. Hsiao, “FePt thin films: Fundamentals and applications” in reference module in materials science and materials engineering, Elsevier, 2016. DOI: https://doi.org/10.1016/B978-0-12-803581-8.02678-3

A. Anders, and E. Oks, “Charge-state-resolved ion energy distribution functions of cathodic vacuum arcs: A study involving the plasma potential and biased plasmas,” Journal of Applied Physics, vol. 101, p. 043304, 2007. DOI: https://doi.org/10.1063/1.2561226

A. Anders, N. Pasaja, S. H. N. Lim, T. C. Petersen, and V. J. Keast, “Plasma biasing to control the growth conditions of diamond-like carbon,” Surface and Coatings Technology, vol. 201, pp. 4628-4632, 2007. DOI: https://doi.org/10.1016/j.surfcoat.2006.09.313

C. Böhm, and J. Perrin, “Retarding-field analyzer for measurements of ion energy distributions and secondary electron emission coefficients in low-pressure radio frequency discharges,” Review of Scientific Instruments, vol. 64, no. 1, pp. 31-44, 1993. DOI: https://doi.org/10.1063/1.1144398

E. A. Edelberg, A. Perry, N. Benjamin, and E. S. Aydil, “Compact floating ion energy analyzer for measuring energy distributions of ions bombarding radio-frequency biased electrode surfaces,” Review of Scientific Instruments, vol. 70, no. 6, pp. 2689-2698, 1999. DOI: https://doi.org/10.1063/1.1149829

V. M. Bardakov, S. D. Ivanov, A. V. Kazantsev, and N. A. Strokin, “Peculiarities of measuring ion energy distribution in plasma with a retarding field analyzer,” Review of Scientific Instruments, vol. 86, p. 053501, 2015. DOI: https://doi.org/10.1063/1.4920998

D. Gahan, S. Daniels, C. Linnane, P. Scullin, D. O’Sullivan, Y. Pei, and M. B. Hopkins, “Ion energy distribution measurements in rf and pulsed dc plasma discharges,” Plasma Sources Science and Technology, vol. 21, no. 2, p. 24004, 2012. DOI: https://doi.org/10.1088/0963-0252/21/2/024004

S. Sharma, D. Gahan, P. Scullin, J. Doyle, J. Lennon, R. K. Vijayaraghavan, S. Daniels, and M. B. Hopkins, “Measurement of deposition rate and ion energy distribution in a pulsed dc magnetron sputtering system using a retarding field analyzer with embedded quartz crystal microbalance,” Review of Scientific

Instruments, vol. 87, no. 87, p. 43511-31507, 2016.

R. A. Pitts, R. Chavan, S. J. Davies, S. K. Erents, G. Kaveney, G. F. Matthews, G. Neill, J. E. Vince, and I. Duran, “Retarding field energy analyzer for the JET plasma boundary,” Review

of Scientific Instruments, vol. 74, no. 11, pp. 4644-4657, 2003. DOI: https://doi.org/10.1063/1.1619554

R. Goldston, and P. Rutherford, Eds., Introduction to Plasma Physics. London, UK: IOP Publishing Ltd, 1995. DOI: https://doi.org/10.1201/9781439822074

F. F. Chen, Plasma Physics in Introduction to Plasma Physics and Controlled Fusion, vol. 1, 2nd ed. NY, USA: Plenum Press, 1984. DOI: https://doi.org/10.1007/978-1-4757-5595-4_1

E. Grossman, G. D. Lempert, J. Kulik, D. Marton, J. W. Rabalais, and Y. Lifshitz, “Role of ion energy in determination of the sp3 fraction of ion beam deposited carbon films,” Applied Physics Letters, vol. 68, p. 1214, 1996. DOI: https://doi.org/10.1063/1.115973

X. L. Peng, Z. H. Barber, and T. W. Clyne, “Surface roughness of diamond-like carbon films prepared using various techniques,” Surface and Coatings Technology, vol. 138, pp. 23-32, 2001. DOI: https://doi.org/10.1016/S0257-8972(00)01139-7

B. Schultrich, “Structure and characterization of vacuum arc deposited carbon films - A critical overview,” Coatings., vol. 12, no. 109, 2022. DOI: https://doi.org/10.3390/coatings12020109

V. Tiron, E. -L. Ursu, D. Cristea, D. Munteanu, G. Bulai, A. Ceban, and I.-L. Velicu, “Overcoming the insulating materials limitation in HiPIMS: Ion-assisted deposition of DLC coatings using bipolar HiPIMS,” Applied Surface Science, vol. 494, pp. 871-879, 2019. DOI: https://doi.org/10.1016/j.apsusc.2019.07.239

N. Menegazzo, M. Kahn, R. Berghauser, and B. Mizaikoff, “Nitrogen-doped diamond-like carbon as optically transparent electrode for infrared attenuated total reflection spectro-electrochemistry,” Analyst, vol. 136, pp. 1831-1839, 2011. DOI: https://doi.org/10.1039/c0an00503g

J. Schwan, S. Ulrich, V. Batori, and H. Ehrhardt, “Raman Spectroscopy on Amorphous Carbon Films,” Journal of Applied Physics, vol. 80, pp. 440447, 1996. DOI: https://doi.org/10.1063/1.362745

T. Koehler, T. Frauenheim, and G. Jungnickel, “Stability, chemical bonding and vibrational properties of amorphous carbon at different mass density,” Physical Review B, vol. 52, no. 16, pp. 11837-11844, 1995.-437. DOI: https://doi.org/10.1103/PhysRevB.52.11837

A. C. Ferrari, A. Libassi, B. K. Tanner, V. Stolojan, J. Yuan, L. M. Brown, S. E. Rodil, B. Kleinsorge, and J. Robertson, “Density, sp3 fraction, and cross-sectional structure of amorphous carbon films determined by x-ray reflectivity and electron energy-loss spectroscopy,” Physical Review B, vol. 62, no. 16, pp. 11089-11103, 2000. DOI: https://doi.org/10.1103/PhysRevB.62.11089

S. S. Roy, R. Mccann, P. Papakonstantinou, P. Maguire, and J. A. Mclaughlin, “The structure of amorphous carbon nitride films using a combined study of NEXAFS, XPS and Raman spectroscopies,” Thin Solid Films, vol. 482, pp. 145-150, 2005. DOI: https://doi.org/10.1016/j.tsf.2004.11.132

L. Skowronski, R. Chodun, M. Trzcinski, and K. Zdunek, “Optical properties of amorphous carbon thin films fabricated using a high-energy-impulse magnetron-sputtering technique,” Materials (Basel), vol. 16, 2023. DOI: https://doi.org/10.3390/ma16217049

Š. Meškinis, A. Vasiliauskas, M. Andrulevičius, D. Peckus, S. Tamulevičius, and K. Viskontas, “Diamond like carbon films containing Si: Structure and nonlinear optical properties,” Materials (Basel), vol. 13, 2020. DOI: https://doi.org/10.3390/ma13041003

K. Ozeki, H. Saitoh, M. Takeda, Y. Ohgoe, K. K. Hirakuri, M. Yonemura, and T. Masuzawa, “Cross-sectional hydrogen content and mass density profiles of diamond-like carbon film by neutron and X-ray reflectivity,” Diamond and Related Materials, vol. 19, pp. 489-491, 2010 DOI: https://doi.org/10.1016/j.diamond.2009.09.017

P. Kumar, M. Gupta, U. P. Deshpande, D. M. Phase, V. Ganesan, and J. Stahn, “Density and microstructure of ta-C thin films,” Diamond and Related Materials, vol. 84, pp. 71-76, 2018. DOI: https://doi.org/10.1016/j.diamond.2018.03.008

Downloads

Published

How to Cite

Issue

Section

Categories

License

Copyright (c) 2024 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.