FEM modeling and comparative study of graphite lubricants in the hot forging of AISI 1045 medium carbon steel

DOI:

https://doi.org/10.55713/jmmm.v35i4.2325Keywords:

Lubricant, Friction factor, Hot forging, Ball joint, FEMAbstract

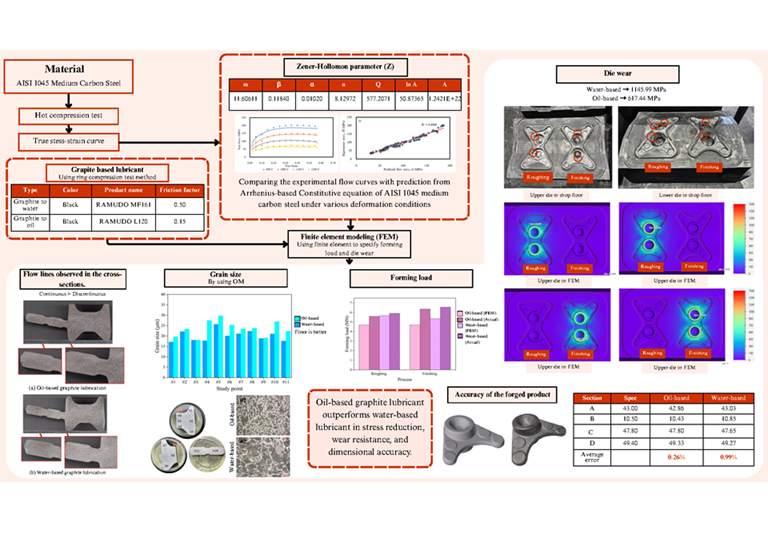

This study investigates the performance of water-based and oil-based graphite lubricants in the hot forging of AISI 1045 medium carbon steel, aiming to enhance product quality while minimizing die wear. Utilizing Finite Element Method (FEM) simulations and experimental analysis, we examined key factors including flow lines, dimensional accuracy, forging load, and die wear. Results indicate that oil-based graphite lubricants significantly outperform water-based options, achieving a lower average error of 0.26% in dimensional accuracy compared to 0.99% for water-based lubricants. Additionally, oil-based lubricants resulted in reduced forming loads, leading to improved energy efficiency and longer die life. Microstructural analysis revealed that oil-based lubrication yielded an average grain size of 13.50 μm, 42.60% finer than the 23.52 μm observed with water-based lubricants, enhancing mechanical properties due to the Hall-Petch relationship. Furthermore, FEM simulations demonstrated that oil-based lubricants produced lower stress levels in dies, correlating with reduced wear. Overall, the findings suggest that oil-based graphite lubricants provide superior performance in hot forging applications, enhancing manufacturing efficiency and product quality. This research underscores the importance of lubricant selection in optimizing forging processes for improved cost-effectiveness and durability in production.

Downloads

References

S. Debin, and Y. Lin, “5.14 - Hot Forging,” in Comprehensive Materials Processing, S. Hashmi, G. F. Batalha, C. J. Van Tyne, and B. Yilbas, Eds. Oxford, U.K.: Elsevier, 2014, pp. 275–289. DOI: https://doi.org/10.1016/B978-0-08-096532-1.00523-9

E. Tempelman, H. Shercliff, and B. N. van Eyben, “Ch. 6 - Forging of Metals,”in Manufacturing and Design, E. Tempelman, H. Shercliff, and B. N. van Eyben, Eds. Boston, MA, USA: Butterworth-Heinemann, 2014, pp. 85–103. DOI: https://doi.org/10.1016/B978-0-08-099922-7.00006-8

C. Caminaga, F. O. Neves, F. C. Gentile, and S. T. Button, “Study of alternative lubricants to the cold extrusion of steel shafts,” Journal of Materials Processing Technology, vol. 182, no. 1, pp. 432–439, 2007. DOI: https://doi.org/10.1016/j.jmatprotec.2006.08.027

N. Karunathilaka, N. Tada, T. Uemori, R. Hanamitsu, M. Fujii, Y. Omiya, and M. Kawano, “Effect of lubrication and forging load on surface roughness, residual stress, and deformation of cold forging tools,” Metals, vol. 9, no. 7, p. 783, 2019. DOI: https://doi.org/10.3390/met9070783

B.-A. Behrens, A. Bouguecha, I. Lüken, J. Mielke, and M. Bistron, “Tribology in hot forging,” Comprehensive Materials Processing, vol. 5, pp. 211–234, 2014. DOI: https://doi.org/10.1016/B978-0-08-096532-1.00538-0

F. Luis Fernando, S. Bruno Caetano dos Santos, B. Gilmar Ferreira, and C. Rodrigo Santiago, “The role of friction on metal forming processes,” Tribology of Machine Elements - Fundamentals and Applications, p. 101387, 2022.

T. Altan, and G. S. Gracious Ngaile, Eds., “Cold and Hot Forging: Fundamentals and Applications, Materials Park, OH, USA: ASM International, 2005, p. 341. DOI: https://doi.org/10.31399/asm.tb.chffa.9781627083003

O. Barrau, C. Boher, R. Gras, and F. Rezai-Aria, “Analysis of the friction and wear behaviour of hot work tool steel for forging,” Wear, vol. 255, no. 7, pp. 1444–1454, 2003. DOI: https://doi.org/10.1016/S0043-1648(03)00280-1

E. Daouben, A. Dubois, M. Dubar, L. Dubar, R. Deltombe, N. G. Truong Dinh, and L. Lazzarotto, “Effects of lubricant and lubrication parameters on friction during hot steel forging,” Intternation Journal of Material Forming, vol. 1, pp. 1223–1226, 2008. DOI: https://doi.org/10.1007/s12289-008-0162-5

Y. Zhu, W. Zeng, X. Ma, Q. Tai, Z. Li, and X. Li, “Determination of the friction factor of Ti-6Al-4V titanium alloy in hot forging by means of ring-compression test using FEM,” Tribology International, vol. 44, no. 12, pp. 2074–2080, 2011. DOI: https://doi.org/10.1016/j.triboint.2011.07.001

K. Asai, and K. Kitamura, “Estimation of frictional property of lubricants for hot forging of steel using low-speed ring compression test,”Procedia Engngineering, vol. 81, pp. 1970–1975, 2014. DOI: https://doi.org/10.1016/j.proeng.2014.10.266

K. Asai, K. Kitamura, N. Yukawa, and N. Hayashi, “Estimation of friction by using improved calibration curves of ring compression test for hot forging of steel,” Procedia Engngineering, vol. 207, pp. 2280–2285, 2017. DOI: https://doi.org/10.1016/j.proeng.2017.10.995

I. Serebriakov, E. S. Puchi-Cabrera, L. Dubar, P. Moreau, D. Meresse, and J. G. La Barbera-Sosa, “Friction analysis during deformation of steels under hot-working conditions,” Tribology International, vol. 158, p. 106928, 2021. DOI: https://doi.org/10.1016/j.triboint.2021.106928

F. Martín, M. J. Martín, L. Sevilla, and M. A. Sebastián, “The ring compression test: Analysis of dimensions and canonical geometry,” Procedia Engngineering, vol. 132, pp. 326–333, 2015. DOI: https://doi.org/10.1016/j.proeng.2015.12.502

V. Mandic, “Friction studies utilizing the ring-compression test—Part I,” Tribology in Industry Journal, vol. 25, 2003.

R. Poungprasert, N. Siripath, and S. Suranuntchai, “A comparative study of lubrication performance for BS 080M46 medium carbon steel using ring compression test and finite element simulation,” Key Engineering Materials, vol. 973, pp. 37–44, 2024. DOI: https://doi.org/10.4028/p-4n5lyD

A. Srivastava, A. Srivastava, and A. Mishra, “Analysis of friction factor & coefficient of friction using ring compression test under various lubricants,” International Journal of Engineering Research and Technology, vol. 9, no. 6, pp. 17–23, 2019. DOI: https://doi.org/10.31873/IJETR.9.6.2019.71

R. Lima, and S. Button, “Application of the finite element method in cold forging processes,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 22, 2000. DOI: https://doi.org/10.1590/S0100-73862000000200005

D. Shahriari, A. Amiri, and M. H. Sadeghi, “Study on hot ring compression test of Nimonic 115 superalloy using experimental observations and 3D FEM simulation,” Journal of Materials Engineering and Performance, vol. 19, no. 5, pp. 633–642, 2010. DOI: https://doi.org/10.1007/s11665-009-9522-7

M. Riaz, and N. Atiqah, “A study on the mechanical properties of S45C medium type carbon steel specimens under lathe machining and quenching conditions,” International Journal of Engineering Research and Technology, vol. 3, pp. 121–130, 2014. DOI: https://doi.org/10.15623/ijret.2014.0312016

CHS-Asia Chemical Co., Ltd., Material safety data sheet RAMUDO L120, Samutprakarn, Thailand, 2017.

CHS-Asia Chemical Co., Ltd., Material safety data sheet RAMUDO MF161, Samutprakarn, Thailand, 2020.

CHS-Asia Chemical Co., Ltd., Product Data Sheet: RAMUDO L120, Bangkok, Thailand, 2018.

CHS-Asia Chemical Co., Ltd., Product Data Sheet: RAMUDO MF161, Bangkok, Thailand, 2017.

H. Yi, J. Ding, C. Ni, J. Dai, Y. Tang, X. Chen, K. Song, and X. Xia, “Hot compression deformation behavior and processing maps of Al–0.5Mg–0.4Si–0.1Cu alloy,” Journal of Materials Research and Technology, vol. 19, pp. 4890–4904, 2022. DOI: https://doi.org/10.1016/j.jmrt.2022.07.027

Y.-C. Lin, M.-S. Chen, and J. Zhang, “Modeling of flow stress of 42CrMo steel under hot compression,” Materials Science and Engineering A, vol. 499, no. 1, pp. 88–92, 2009. DOI: https://doi.org/10.1016/j.msea.2007.11.119

V. K. Kumar, and Neelam, “Modeling and multiple performance optimization of ultrasonic micro-hole machining of PCD using fuzzy logic and Taguchi quality loss function,” Advanced Materials Research, vol. 1, no. 2, pp. 129–146, 2012. DOI: https://doi.org/10.12989/amr.2012.1.2.129

N. Siripath, S. Suranuntchai, and S. Sucharitpwatskul, “Comparative study on material models for BS 080M46 medium carbon steel,” Engineering and Applied Science Research, vol. 51, no. 1, p. 22, 2024.

C. Zener, and J. H. Hollomon, “Effect of strain rate upon plastic flow of steel,” Journal of Applied Physics, vol. 15, no. 1, pp. 22–32, 1944. DOI: https://doi.org/10.1063/1.1707363

Y. Xu, P. Birnbaum, S. Pilz, X. Zhuang, Z. Zhao, and V. Kräusel, “Investigation of constitutive relationship and dynamic recrystallization behavior of 22MnB5 during hot deformation,” Results in Physics, vol. 14, p. 102426, 2019. DOI: https://doi.org/10.1016/j.rinp.2019.102426

Z. Xiao, Q. Wang, Y. Huang, J. Hu, and M. Li, “Hot deformation characteristics and processing parameter optimization of Al-632Zn-210Mg alloy using constitutive equation and processing map,” Metals, vol. 11, no. 2, p. 360, 2021. DOI: https://doi.org/10.3390/met11020360

T. R. Dandekar, R. K. Khatirkar, A. Gupta, N. Bibhanshu, A. Bhadauria, and S. Suwas, “Strain rate sensitivity behaviour of Fe–21Cr-1.5Ni–5Mn alloy and its constitutive modelling,” Materials Chemistry and Physics, vol. 271, p. 124948, 2021. DOI: https://doi.org/10.1016/j.matchemphys.2021.124948

Q. Liang, X. Liu, P. Li, P. Ding, and X. Zhang, “Development and application of high-temperature constitutive model of HNi55-7-4-2 alloy,” Metals, vol. 10, no. 9, p. 1250, 2020. DOI: https://doi.org/10.3390/met10091250

X. Chen, N. Wang, X. Ma, and H. Zhou, “Hot deformation behaviour and Hansel-Spittel constitutive model of Cr5 alloy for heavy backup roll,” International Journal of Computational Materials Science and Surface Engineering, vol. 7, no. 3–4, pp. 205–217, 2018. DOI: https://doi.org/10.1504/IJCMSSE.2018.095321

M. C. Kim, S. H. Chung, and M. S. Joun, “Optimal process design in hot forging in terms of grain flow quality,” International Journal of Automotive Technology, vol. 20, no. 1, pp. 45–56, 2019. DOI: https://doi.org/10.1007/s12239-019-0127-3

Downloads

Published

How to Cite

License

Copyright (c) 2025 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.