Influence of six-step heat treatment on microstructures and mechanical properties of 5160 alloy steel

DOI:

https://doi.org/10.55713/jmmm.v32i1.1141คำสำคัญ:

Quenching, Tempering, Microstructure, Mechanical Properties, AISI 5160บทคัดย่อ

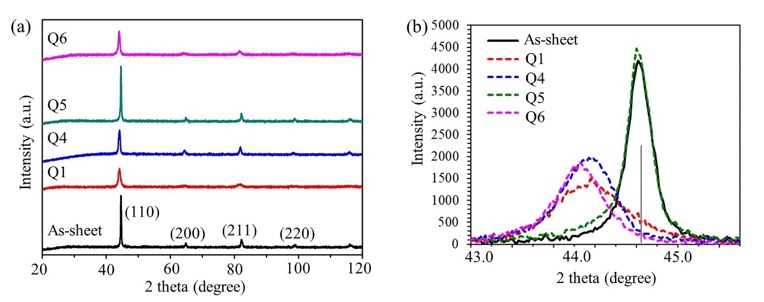

AISI 5160 alloy steel grade with complete martensite structure to get the high-strength steel sheets quenched at 900 (Q1), 870 (Q2), 840 (Q3) and 810°C (Q4), respectively and temped at 780°C (Q5) and 680°C (Q6), respectively. The results show ferrite and pearlite microstructural appeared in as-sheet conditions. The strengthening rarely increased with increasing heat treatment steps, while the percentage elongation gradually decreased. The hardness change was secure with that of strengthening for the quenched martensite. In contrast, differences between the initial martensite hardness were no noticeable changes. The Q4 hardening involved the peak hardness and maximum ultimate tensile strength due to carbide distribution in the martensite matrix. The coarse ferrite grains have occurred after Q5 cause significantly reduced hardness and tensile strength. However, the percentage elongation increased with increasing quenching step to Q5 hardening. The excellent 5160 steel performed by Q6 hardening characteristic gained most hardness, ultimate tensile strength, and elongation approximately 60 HRC, 835 MPa, and 12.09%, respectively. Martensite structure transformed to among carbide distribution tempered martensite matrix.

Downloads

เอกสารอ้างอิง

M. S. Htun, S. T. Kyaw, and K. T. Lwin, “Effect of heat treatment on microstructures and mechanical properties of spring steel,” Journal of Metals, Materials and Minerals, vol. 18, no. 2, pp. 191-197, 2008.

W. H. Zhou, H. Guo, Z. J. Xie, X. M. Wang, and C. J. Shang, “High strength low-carbon alloyed steel with good ductility by combining the retained austenite and nano-sized precipitates,” Materials Science and Engineering A, vol. 587, pp. 365-371, 2013.

W. H. Zhou, X. L. Wang, P. K. C. Venkatsurya, H. Guo, C. J. Shang, and R. D. K. Misra, “Structure–mechanical property relationship in a high strength low carbon alloy steel processed by two-step intercritical annealing and intercritical tempering,” Materials Science and Engineering A, vol. 607, pp. 569-577, 2014.

S. Wang, H. Yu, T. Zhou, L. Wang, “Synergetic effects of ferrite content and tempering Temperature on mechanical properties of a 960 MPa grade HSLA steel,” Materials, vol. 11, no. 2049, pp. 1-13, 2018.

J. H. Jang, J. Moon, H.-Y. Ha, T.-H. Lee, and D.-W. Suh, “Quantum-mechanical analysis of effect of alloying elements on ε-martensite start temperature of steels,” Scientific Reports, vol. 7, no 17860, pp 1-11, 2017.

J. Sas, T. Kvačkaj, O. Milkovič, and M. Zemko, “Influence of hot plastic deformation in γ and (γ + α) area on the structure and mechanical properties of high-strength low-alloy (HSLA) steel,” Materials, vol. 9, no. 971, pp. 1-8, 2016.

G. Sahoo, K. K. Singh, and V. Kumar, “Quenched and tempered high strength steel: A review,” Journal of Metals, Materials and Minerals, vol. 30, no. 4, pp. 19-29, 2020.

W. H. Zhou, H. Guo, Z. J. Xie, C. J. Shang, and R. D. K. Misra, “Copper precipitation and its impact on mechanical properties in a low carbon microalloyed steel processed by a three-step heat treatment,” Materials and Design, vol. 63, pp. 42-49, 2014.

Z.-J. Xie, C.-J. Shang, X.-L. Wang, X.-M. Wang, G. Han, and R.-D.-K. Misra, “Recent progress in third-generation low alloy steels developed under M3 microstructure control,” International Journal of Minerals, Metallurgy and Materials, vol. 27, no. 1, pp. 1-9, 2020.

Z. Pan, B. Gao, Q. Lai, X. Chen, Y. Cao, M. Liu, and H. Zhou, “Microstructure and mechanical properties of a cold-rolled ultrafine-grained dual-phase steel,” Materials, vol. 11, no. 1399, pp. 1-11, 2018.

H. Guo, X. Feng, A. Zhao, Q. Li, and J. Ma, “Influence of prior martensite on bainite transformation, microstructures, and mechanical properties in ultra-fine bainitic steel,” Materials, vol. 12, no. 527, pp. 1-15, 2019.

D. E. Lozano, G. E. Totten, Y. Bedolla-Gil, M. Guerrero-Mata, M. Carpio, and G. M. Martinez-Cazares, “X-ray determination of compressive residual stresses in spring steel generated by high-speed water quenching,” Materials, vol. 12, no. 1154, pp. 1-11, 2019.

Q. Luo, “A new XRD method to quantify plate and lath martensites of hardened medium-carbon steel,” Journal of Materials Engineering and Performance, vol. 25, no. 6, pp. 2170-2179, 2016.

H. L. Yi, K. Y. Lee, and H. K. D. H. Bhadeshi, “Mechanical stabilisation of retained austenite in δ-TRIP steel,” Materials Science and Engineering A, vol. 528, pp. 1-9, 2011.

A. Stormvinter, A. Borgenstam, and P. Hedström, “Investigation of lath and plate martensite in a carbon steel,” Solid State Phenomena, vol. 172-174, pp. 61-66, 2011.

P. Apichai, “Effects of quenchants on microstructures and mechanical properties of steel grade AISI 5160,” Journal of Metals, Materials and Minerals, vol. 30, no. 3, pp. 15-23, 2020.

C. G. Andrѐs, G. Caruana, and L. F. Alvarez, “Control of M23C6 carbides in 0.45C-13Cr martensitic stainless steel by means of three representative heat treatment parameters,” Materials Science and Engineering A, vol. 241, no. 1-2, pp. 211-215, 1998.

A. F. Candelária, and C. E. Pinedo, “Influence of the heat treatment on the corrosion resistance of the martensitic stainless steel type AISI 420,” Journal of Materials Science Letters, vol. 22, pp. 1151-1153, 2003.

W. Liu, Y.-H. Jiang, H. Guo, Y. Zhang, A.-M. Zhao, and Y. Huang, “Mechanical properties and wear resistance of ultrafine bainitic steel under low austempering temperature,” International Journal of Minerals, Metallurgy and Materials, vol. 27, no. 4, pp. 483-493, 2020.

V. H. B. Hernandez, S. S. Nayak, and Y. Zhou, “Tempering of martensite in dual-phase steels and its effects on softening behavior,” Metallurgical and Materials Transactions A. vol. 42A, pp. 3115-3129, 2011.

Y. I. Son, Y. K. Lee, K. T. Park, C. S. Lee, and D. H. Shin, “Ultrafine grained ferrite–martensite dual phase steels fabricated via equal channel angular pressing: microstructure and tensile properties,” Acta Materialia, vol. 53, pp. 3125-3134, 2005.

K. T. Park, Y. K. Lee, and D. H. Shin, “Fabrication of ultrafine grained ferrite/martensite dual phase steel by severe plastic deformation,” The Iron and Steel Institute of Japan International, vol. 45, pp. 750-755, 2005.

R. Ding, D. Tang, A. Zhao, H. Guo, J. He, and C. Zhi, “Effect of ultragrain refinement on quenching and partitioning steels manufactured by a novel method,” Materials and Design, vol. 87, pp. 640-649, 2015.

A. F. Brust, S. R. Niezgoda, V. A. Yardley, and E. J. Payton, “Analysis of misorientation relationships between austenite parents and twins,” Metallurgical and Materials Transactions A, vol. 50, pp. 837-855, 2019.

A. Turk, G. R. Joshi, M. Gintalas, M. Callisti, P. E. J. Rivera-DÃaz-del-Castillo, and E. I. Galindo-Nava, “Quantification of hydrogen trapping in multiphase steels: part I - point traps in martensite,” Acta Materialia, vol. 194, pp. 118-133, 2020.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.