Preparation of bacterial cellulose film from rotten fruits for mulching film application

DOI:

https://doi.org/10.55713/jmmm.v32i4.1535คำสำคัญ:

Acetobacter xylinum, Bacterial cellulose, Mulching film, Rotten fruits, Solvent castingบทคัดย่อ

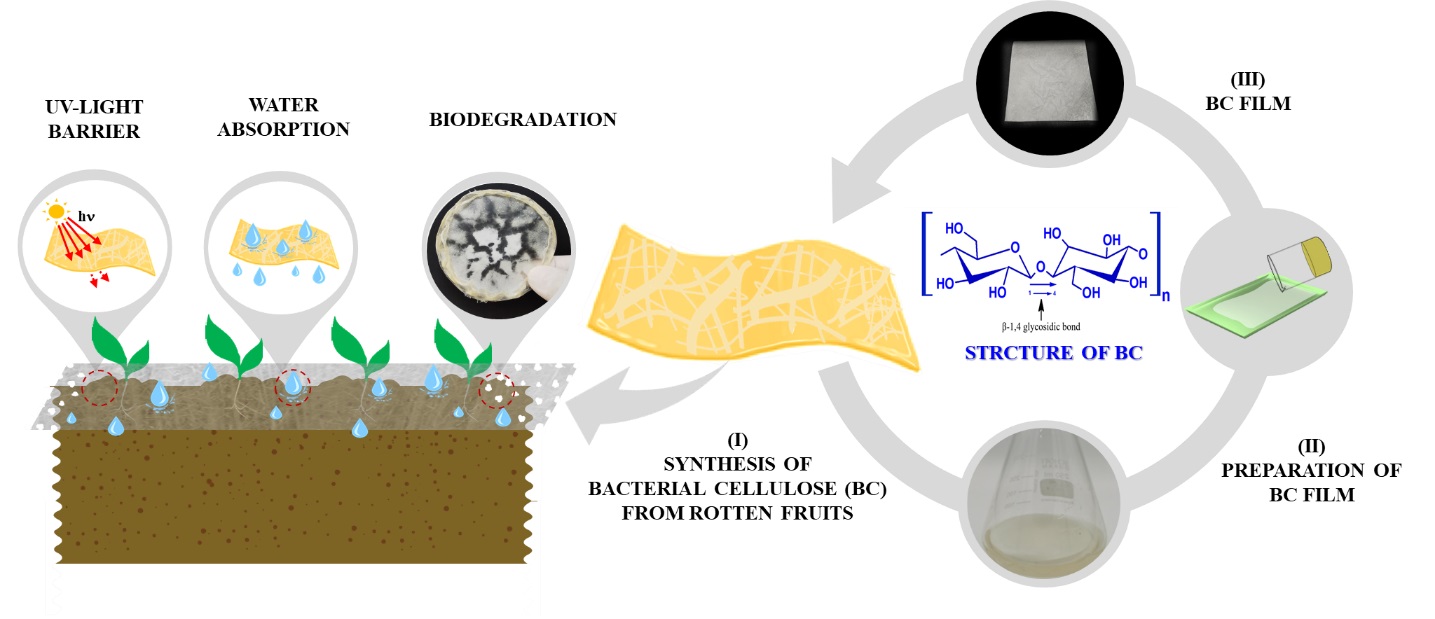

This research aims to reduce production capital costs and added value to natural products. The bio-mulching film was prepared by bacterial cellulose (BC) “Acetobacter xylinum”, extracted from three rotten fruits, grape, coconut, and pineapple under standard tests in the laboratory. The analysis from the FTIR technique confirmed to cellulose molecular vibration of BC films. XRD pattern was matched to structure crystallinity of JCPDS standard file which possessed a high percentage of crystallinity. The SEM micrographs were also revealed the 3D nanofiber network structure. The absorption capability of BC films could highly hold water in its structure. In addition, the mechanical properties of BC films came from rotten coconut, given the highest tensile strength (7.2 ± 1.1 MPa) according to nano-fiber symmetric with its dense structure. Nevertheless, the soil burial testing emphasized BC films could reduce soil temperature and increase moisture content in the soil as well. The biodegradation rate of BC films in 30 days was moderately fair. The BC film from rotten coconut had the slowest biodegradation rate (approximately 22.3 4.2%), applicable to biodegradable mulching film.

Downloads

เอกสารอ้างอิง

Z. Ma, Y. Ma, L. Qin, J. Liu, and H. Su, "Preparation and characteristics of biodegradable mulching films based on fermentation industry wastes," International Biodeterioration & Biodegradation, vol. 111, pp. 54-61, 2016.

Z. Wang, Q. Wu, B. Fan, J. Zhang, W. Li, X. Zheng, H. Lin, and L. Guo, "Testing biodegradable films as alternatives to plastic films in enhancing cotton (Gossypium hirsutum L.) yield under mulched drip irrigation," Soil and Tillage Research, vol. 192, pp. 196-205, 2019.

S. Kasirajan, and M. Ngouajio, "Polyethylene and biodegradable mulches for agricultural applications: A review," Agronomy for Sustainable Development, vol. 32, no. 2, pp. 501-529, 2012.

N. Pinpru, and S. Woramongkolchai, "Crosslinking effects on alginate/carboxymethyl cellulose packaging film properties," Chiang Mai Journal of Science, vol. 47, no. 4, pp. 712-722, 2020.

M. Sander, "Biodegradation of polymeric mulch films in agricultural soils: Concepts, knowledge gaps, and future research directions," Environmental Science and Technology, vol. 53, no. 5, pp. 2304-2315, 2019.

A. Vazquez, M. L. Foresti, P. Cerrutti, and M. Galvagno, "Bacterial cellulose from simple and low cost production media by gluconacetobacter xylinus," Journal of Polymers and the Environment, vol. 21, no. 2, pp. 545-554, 2012.

F. Jahan, V. Kumar, G. Rawat, and R. K. Saxena, "Production of microbial cellulose by a bacterium isolated from fruit," Appl Biochem Biotechnol, vol. 167, no. 5, pp. 1157-1171, 2012.

P. Moonsungnoen, D. Ochaikul, and P. Monvisade, "Bacterial cellulose and bacterial cellulose/chitosan films containing mangosteen pericarp extract for wound dressings," Chiang Mai Journal of Science, vol. 48, no. 4, pp. 952-968, 2021.

M. Moniri, A. B. Moghaddam, S. Azizi, R. A. Rahim, A. B. Ariff, W. Z. Saad, M. Navaderi, and R. Mohamad, "Production and Status of Bacterial Cellulose in Biomedical Engineering," Nanomaterials (Basel), vol. 7, no. 9, p. 257, 2017.

P. Cazon, G. Velazquez, and M. Vazquez, "Characterization of bacterial cellulose films combined with chitosan and polyvinyl alcohol: Evaluation of mechanical and barrier properties," Carbohydrate Polymers, vol. 216, pp. 72-85, 2019.

R. Naomi, R. B. H. Idrus, and M. B. Fauzi, "Plant- vs. Bacterial-derived cellulose for wound healing: A review," International Journal of Environmental Research and Public Health, vol. 17, no. 18, p. 6803, 2020.

K. A. Zahan, N. M. Azizul, M. Mustapha, W. Y. Tong, M. S. A. Rahman, and I. S. Sahuri, "Application of bacterial cellulose film as a biodegradable and antimicrobial packaging material," Materials Today: Proceedings, vol. 31, pp. 83-88, 2020.

A. Abduwaiti, X. Liu, C. Yan, Y. Xue, T. Jin, H. Wu, P. He, Z. Bao, and Q. Liu, "Testing biodegradable films as alternatives to plastic-film mulching for enhancing the yield and economic benefits of processed tomato in xinjiang region," Sustainability, vol. 13, no. 6, p. 3093, 2021.

C. R. D. Franco, V. P. Cyras, J. P. Busalmen, R. A. Ruseckaite, and A. Vázquez, "Degradation of polycaprolactone/starch blends and composites with sisal fibre," Polymer Degradation and Stability, vol. 86, no. 1, pp. 95-103, 2004.

G. Gayathri and G. Srinikethan, "Bacterial cellulose production by K. saccharivorans BC1 strain using crude distillery effluent as cheap and cost effective nutrient medium," International Journal of Biological Macromolecules, vol. 138, pp. 950-957, 2019.

H. Khan, A. Kadam, and D. Dutt, "Studies on bacterial cellulose produced by a novel strain of Lactobacillus genus," Carbohydrate Polymers, vol. 229, p. 115513, 2020.

V. Andritsou, E. M. D. Melo, E. Tsouko, D. Ladakis, S. Maragkoudaki, A. A. Koutinas, and A. S. Matharu, "Synthesis and characterization of bacterial cellulose from citrus-based sustainable resources," ACS Omega, vol. 3, no. 8, pp. 10365-10373, 2018.

C. M. Lee, J. Gu, K. Kafle, J. Catchmark, and S. H. Kim, "Cellulose produced by Gluconacetobacter xylinus strains ATCC 53524 and ATCC 23768: Pellicle formation, post-synthesis aggregation and fiber density," Carbohydrate Polymers, vol. 133, pp. 270-276, 2015.

B. Sun, L. Zhang, F. Wei, A. AL-Ammari, X. Xu, W. Li, C. Cgen, J. Lin, H. Zhang, and D. Sun, "In situ structural modification of bacterial cellulose by sodium fluoride," Carbohydrate Polymers, vol. 231, p. 115765, 2020.

C. Moukamnerd, K. Ounmuang, N. Konboa, and C. Insomphun, "Bacterial cellulose production by Komagataeibacter nataicola TISTR 2661 by agro-waste as a carbon source," Chiang Mai Journal of Science, vol. 47, no. 1, pp. 16-27, 2020.

N. Pinpru, T. Charoonsuk, S. Khaisaat, O. Sawanakarn, N. Vittayakorn, and S. Woramongkolchai, "Synthesis and preparation of bacterial cellulose/calcium hydrogen phosphate composite film for mulching film application," Materials Today: Proceedings, vol. 47, pp. 3529-3536, 2021.

S. H. Lee, S. J. An, Y. M. Lim, and J. B. Huh, "The efficacy of electron beam irradiated bacterial cellulose membranes as compared with collagen membranes on guided bone regeneration in peri-implant bone defects," Materials (Basel), vol. 10, no. 9, p. 1018, 2017.

P. Cazón, G. Velazquez, and M. Vázquez, "UV-protecting films based on bacterial cellulose, glycerol and polyvinyl alcohol: effect of water activity on barrier, mechanical and optical properties," Cellulose, vol. 27, no. 14, pp. 8199-8213, 2020.

H. Sadeghifar, R. Venditti, J. Jur, R. E. Gorga, and J. J. Pawlak, "Cellulose-lignin biodegradable and flexible UV protection film," ACS Sustainable Chemistry & Engineering, vol. 5, no. 1, pp. 625-631, 2016.

R. Portela, C. R. Leal, P. L. Almeida, and R. G. Sobral, "Bacterial cellulose: a versatile biopolymer for wound dressing applications," Microbial Biotechnology, vol. 12, no. 4, pp. 586-610, 2019.

T. Sun, G. Li, T. Y. Ning, Z. M. Zhang, Q. H. Mi, and R. Lal, "Suitability of mulching with biodegradable film to moderate soil temperature and moisture and to increase photosynthesis and yield in peanut," Agricultural Water Management, vol. 208, pp. 214-223, 2018.

D. Chmolowska, N. Hamda, and R. Laskowski, "Cellulose decomposed faster in fallow soil than in meadow soil due to a shorter lag time," Journal of Soils and Sediments, vol. 17, no. 2, pp. 299-305, 2016.

E. M. N. Polman, G. J. M. Gruter, J. R. Parsons, and A. Tietema, "Comparison of the aerobic biodegradation of biopolymers and the corresponding bioplastics: A review," Science of the Total Environment, vol. 753, p. 141953, 2021.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.