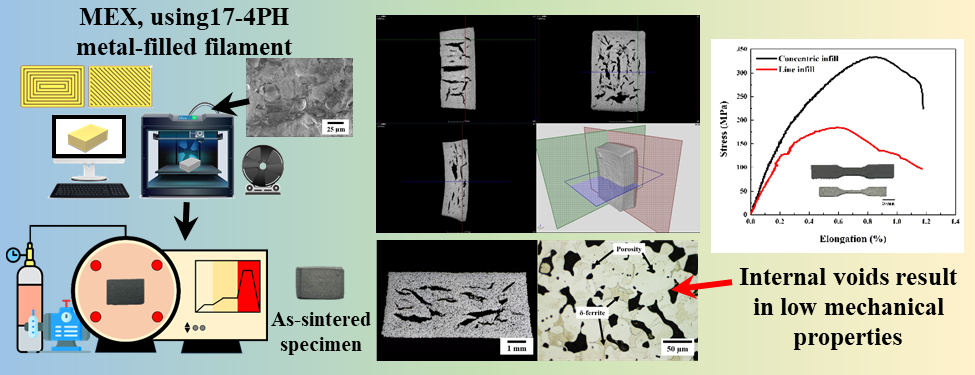

The effect of printing parameters on the properties of 17-4 PH stainless steel fabricated by material extrusion additive manufacturing

DOI:

https://doi.org/10.55713/jmmm.v34i2.1804คำสำคัญ:

additive manufacturing, printing parameter, 17-4PH, sintering, densityบทคัดย่อ

The 17-4PH stainless steel filament was characterised and utilised to study the effect of printing parameters, i.e. printing temperature, layer thickness, infill pattern and extrusion multiplier on the physical properties. The as-printed and as-sintered internal structures were analysed. The results showed that the as-printed density increases with increasing printing temperature and extrusion multiplier and decreasing layer thickness. The use of the line infill pattern also provided slightly higher as-printed density than the concentric infill pattern due to the low fraction of void between deposited paths. After sintering, the trace of these voids can be observed together with smaller-size residual pores from the spaces between powders, which is the nature of the pressureless sintering process. The microstructure of the as-sintered specimens was similar to the typical microstructure of the 17-4PH alloy fabricated by metal injection moulding process, which contains delta ferrite, martensite and Si-rich phases. In additions, the internal void generated during debinding and sintering results in unexpectedly low tensile properties and results in the difference in tensile properties between the concentric and line infill patterns.

Downloads

เอกสารอ้างอิง

D. Barba, C. Alabort, Y. T. Tang, M. J. Viscasillas, R. C. Reed, and E. Alabort, "On the size and orientation effect in additive manufactured Ti-6Al-4V," Materials & Design, vol. 186, p. 108235, 2020. DOI: https://doi.org/10.1016/j.matdes.2019.108235

R. A. Michi, A. Plotkowski, A. Shyam, R. R. Dehoff, and S. S. Babu, "Towards high-temperature applications of aluminium alloys enabled by additive manufacturing," International Materials Reviews, pp. 1-48, 2021. DOI: https://doi.org/10.1080/09506608.2021.1951580

T. DebRoy, H. L. Wei, J. S. Zuback, T. Mukherjee, J. W. Elmer, J. O. Milewski, A. M. Beese, A. Wilson-Heid, A. De, and W. Zhang, "Additive manufacturing of metallic components – Process, structure and properties," Progress in Materials Science, vol. 92, pp. 112-224, 2018. DOI: https://doi.org/10.1016/j.pmatsci.2017.10.001

W. E. Frazier, "Metal additive manufacturing: A review," Journal of Materials Engineering and Performance, vol. 23, no. 6, pp. 1917-1928, 2014. DOI: https://doi.org/10.1007/s11665-014-0958-z

I. Thawon, T. Fongsamootr, Y. Mona, and P. Suttakul, "Investigation of the mechanical properties of additively manufactured metal parts with different relative densities," Applied Sciences, vol. 12, no. 19, p. 9915, 2022. DOI: https://doi.org/10.3390/app12199915

J. Gonzalez-Gutierrez, S. Cano, S. Schuschnigg, C. Kukla, J. Sapkota, and C. Holzer, "Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: A review and future perspectives," Materials, vol. 11, no. 5, p. 840, 2018. DOI: https://doi.org/10.3390/ma11050840

C. Suwanpreecha, and A. Manonukul, "A review on material extrusion additive manufacturing of metal and how it compares with metal injection moulding," Metals, 2022. DOI: https://doi.org/10.3390/met12030429

S. Riecker, J. Clouse, T. Studnitzky, O. Andersen, and B. Kieback, "Fused deposition modeling-opportunities for cheap metal AM," World PM2016-AM-Deposition Technologies, 2016.

H. Gong, D. Snelling, K. Kardel, and A. Carrano, "Comparison of stainless steel 316L parts made by FDM- and SLM-based additive manufacturing processes," JOM, vol. 71, no. 3, pp. 880-885, 2019. DOI: https://doi.org/10.1007/s11837-018-3207-3

D. Godec, S. Cano, C. Holzer, and J. Gonzalez-Gutierrez, "Optimization of the 3D printing parameters for tensile properties of specimens produced by fused filament fabrication of 17-4PH stainless steel," Materials, vol. 13, no. 3, p. 774, 2020. DOI: https://doi.org/10.3390/ma13030774

M. Á. Caminero, A. Romero, J. M. Chacón, P. J. Núñez, E. García-Plaza, and G. P. Rodríguez, "Additive manufacturing of 316L stainless-steel structures using fused filament fabrication technology: Mechanical and geometric properties," Rapid Prototyping Journal, 2021. DOI: https://doi.org/10.1108/RPJ-06-2020-0120

Y. Wang, L. Zhang, X. Li, and Z. Yan, "On hot isostatic pressing sintering of fused filament fabricated 316L stainless steel – evaluation of microstructure, porosity, and tensile properties," Materials Letters, p. 129854, 2021. DOI: https://doi.org/10.1016/j.matlet.2021.129854

M. Quarto, M. Carminati, and G. D’Urso, "Density and shrinkage evaluation of AISI 316L parts printed via FDM process," Materials and Manufacturing Processes, pp. 1-9, 2021. DOI: https://doi.org/10.1080/10426914.2021.1905830

M. A. Wagner, A. Hadian, T. Sebastian, F. Clemens, T. Schweizer, M. Rodriguez-Arbaizar, E. Carreño-Morelli, and R. Spolenak, "Fused filament fabrication of stainless steel structures - from binder development to sintered properties," Additive Manufacturing, p. 102472, 2021. DOI: https://doi.org/10.1016/j.addma.2021.102472

C. Suwanpreecha, and A. Manonukul, "On the build orientation effect in as-printed and as-sintered bending properties of 17-4PH alloy fabricated by metal fused filament fabrication," Rapid Prototyping Journal, vol. ahead-of-print, no. ahead-of-print, 2022. DOI: https://doi.org/10.1108/RPJ-07-2021-0174

C. Suwanpreecha, P. Seensattayawong, V. Vadhanakovint, and A. Manonukul, "Influence of specimen layout on 17-4PH (AISI 630) alloys fabricated by low-cost additive manufacturing," Metallurgical and Materials Transactions A, 2021. DOI: https://doi.org/10.1007/s11661-021-06211-x

J. Gonzalez-Gutierrez, F. Arbeiter, T. Schlauf, C. Kukla, and C. Holzer, "Tensile properties of sintered 17-4PH stainless steel fabricated by material extrusion additive manufacturing," Materials Letters, vol. 248, pp. 165-168, 2019. DOI: https://doi.org/10.1016/j.matlet.2019.04.024

Y.-H. Cho, S.-Y. Park, J.-Y. Kim, and K.-A. Lee, "17-4PH stainless steel with excellent strength–elongation combination developed via material extrusion additive manufacturing," Journal of Materials Research and Technology, vol. 24, pp. 3284-3299, 2023. DOI: https://doi.org/10.1016/j.jmrt.2023.03.228

Y. Abe, T. Kurose, M. V. Santos, Y. Kanaya, A. Ishigami, S. Tanaka, and H. Ito, "Effect of layer directions on internal structures and tensile properties of 17-4PH stainless steel parts fabricated by fused deposition of metals," Materials, vol. 14, no. 2, p. 243, 2021. DOI: https://doi.org/10.3390/ma14020243

J. A. Naranjo, C. Berges, A. Gallego, and G. Herranz, "A novel printable high-speed steel filament: Towards the solution for wear-resistant customized tools by AM alternative," Journal of Materials Research and Technology, vol. 11, pp. 1534-1547, 2021. DOI: https://doi.org/10.1016/j.jmrt.2021.02.001

Y. Thompson, M. Polzer, J. Gonzalez-Gutierrez, O. Kasian, J. P. Heckl, V. Dalbauer, C. Kukla, and P. J. Felfer, "Fused filament fabrication‐based additive manufacturing of commercially pure titanium," Advanced Engineering Materials, vol. 23, no. 12, p. 2100380, 2021. DOI: https://doi.org/10.1002/adem.202100380

Z. Lu, O. I. Ayeni, X. Yang, H.-Y. Park, Y.-G. Jung, and J. Zhang, "Microstructure and phase analysis of 3D-printed components using bronze metal filament," Journal of Materials Engineering and Performance, vol. 29, no. 3, pp. 1650-1656, 2020. DOI: https://doi.org/10.1007/s11665-020-04697-x

J. Gonzalez-Gutierrez, S. Cano, J. V. Ecker, M. Kitzmantel, F. Arbeiter, C. Kukla, and C. Holzer, "Bending properties of lightweight copper specimens with different infill patterns produced by material extrusion additive manufacturing, solvent debinding and sintering," Applied Sciences, vol. 11, no. 16, p. 7262, 2021. DOI: https://doi.org/10.3390/app11167262

X. Wei, I. Behm, T. Winkler, S. Scharf, X. Li, and R. Bähr, "Experimental study on metal parts under variable 3D printing and sintering orientations using bronze/PLA hybrid filament coupled with fused filament fabrication," Materials, vol. 15, no. 15, p. 5333, 2022. DOI: https://doi.org/10.3390/ma15155333

B. Aruanno, A. Paoli, A. V. Razionale, and F. Tamburrino, "Effect of printing parameters on extrusion-based additive manufacturing using highly filled CuSn12 filament," The International Journal of Advanced Manufacturing Technology, pp. 1-14, 2023. DOI: https://doi.org/10.1007/s00170-023-11919-8

P. Singh, V. K. Balla, A. Gokce, S. V. Atre, and K. H. Kate, "Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): producing parts comparable to that of metal injection molding," Progress in Additive Manufacturing, vol. 6, no. 5, 2021. DOI: https://doi.org/10.1007/s40964-021-00167-5

P. Singh, V. K. Balla, S. V. Atre, R. M. German, and K. H. Kate, "Factors affecting properties of Ti-6Al-4V alloy additive manufactured by metal fused filament fabrication," Powder Technology, vol. 386, pp. 9-19, 2021. DOI: https://doi.org/10.1016/j.powtec.2021.03.026

Y. Zhang, S. Bai, M. Riede, E. Garratt, and A. Roch, "A comprehensive study on Fused filament fabrication of Ti-6Al-4V structures," Additive Manufacturing, p. 101256, 2020. DOI: https://doi.org/10.1016/j.addma.2020.101256

P. Singh, V. K. Balla, A. Tofangchi, S. V. Atre, and K. H. Kate, "Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3)," International Journal of Refractory Metals and Hard Materials, vol. 91, p. 105249, 2020. DOI: https://doi.org/10.1016/j.ijrmhm.2020.105249

G. Kiswanto, A. Kholil, and J. Istiyanto, "Effect of infill pattern on impact toughness, microstructure, and surface roughness of inconel 625 built via filament-based material extrusion additive manufacturing," Journal of Manufacturing and Materials Processing, vol. 7, no. 3, p. 114, 2023. DOI: https://doi.org/10.3390/jmmp7030114

Y. Thompson, K. Zissel, A. Förner, J. Gonzalez-Gutierrez, C. Kukla, S. Neumeier, and P. Felfer, "Metal fused filament fabrication of the nickel-base superalloy IN 718," Journal of Materials Science, pp. 1-15, 2022. DOI: https://doi.org/10.1007/s10853-022-06937-y

"Ultrafuse 316L, https://www.ultrafusefff.com/product-category/ metal/ultrafuse-316l/ (accessed on 27 October 2021)."

"The virtual foundry, printing pure metal with filamet™, https:// www. thevirtualfoundry.com/help, (accessed on 27 October 2021)."

M. Q. Shaikh, P.-Y. Lavertu, K. H. Kate, and S. V. Atre, "Process sensitivity and significant parameters investigation in metal fused filament fabrication of Ti-6Al-4V," Journal of Materials Engineering and Performance, vol. 30, no. 5, pp. 5118-5138, 2021. DOI: https://doi.org/10.1007/s11665-021-05666-8

T. Kurose, Y. Abe, M. V. Santos, Y. Kanaya, A. Ishigami, S. Tanaka, and H. Ito, "Influence of the layer directions on the properties of 316L stainless steel parts fabricated through fused deposition of metals," Materials, vol. 13, no. 11, p. 2493, 2020. DOI: https://doi.org/10.3390/ma13112493

W. Hassan, M. A. Farid, A. Tosi, K. Rane, and M. Strano, "The effect of printing parameters on sintered properties of extrusion-based additively manufactured stainless steel 316L parts," The International Journal of Advanced Manufacturing Technology, vol. 114, no. 3, pp. 1-11, 2021. DOI: https://doi.org/10.1007/s00170-021-07047-w

G. Singh, J.-M. Missiaen, D. Bouvard, and J.-M. Chaix, "Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization," Additive Manufacturing, vol. 38, p. 101778, 2021. DOI: https://doi.org/10.1016/j.addma.2020.101778

T. Rosnitschek, A. Seefeldt, B. Alber-Laukant, T. Neumeyer, V. Altstädt, and S. Tremmel, "Correlations of geometry and infill degree of extrusion additively manufactured 316L stainless steel components," Materials, vol. 14, no. 18, p. 5173, 2021. DOI: https://doi.org/10.3390/ma14185173

A. S. f. Testing and Materials, "B962-17: standard test methods for density of compacted or sintered Powder Metallurgy (PM) products using archimedes’ principle," 2019: ASTM West Conshohocken.

K. Gante Lokesha Renukaradhya, "Metal filament 3D printing of SS316L: Focusing on the printing process," ed, 2019.

A. Bhaduri, S. Sujith, G. Srinivasan, T. Gill, and S. Mannan, "Optimized postweld heat treatment procedures for 17-4 PH stainless steels," Welding Journal, vol. 74, no. 5, p. 153, 1995. DOI: https://doi.org/10.1179/136217199101537905

J. R. Davis, Stainless steels. ASM international, 1994.

P. Suri, B. Smarslok, and R. M. German, "Impact properties of sintered and wrought 17–4 PH stainless steel," Powder metallurgy, vol. 49, no. 1, pp. 40-47, 2006. DOI: https://doi.org/10.1179/174329006X89317

R. Schroeder, G. Hammes, C. Binder, and A. N. Klein, "Plasma debinding and sintering of metal injection moulded 17-4PH stainless steel," Materials Research, vol. 14, pp. 564-568, 2011. DOI: https://doi.org/10.1590/S1516-14392011005000082

R. J. Hamlin and J. N. DuPont, "Microstructural evolution and mechanical properties of simulated heat-affected zones in cast precipitation-hardened stainless steels 17-4 and 13-8+ Mo," Metallurgical and Materials Transactions A, vol. 48, no. 1, pp. 246-264, 2017. DOI: https://doi.org/10.1007/s11661-016-3851-6

MPIF, "Material standards for metal injection molded parts," Princeton, NJ, Metal Powder Industries Federation. 2016.

G. Singh, J.-M. Missiaen, D. Bouvard, and J.-M. Chaix, "Additive manufacturing of 17-4 PH steel using metal injection moulding feedstock: analysis of 3D extrusion printing, debinding and sintering," Additive Manufacturing, p. 102287, 2021. DOI: https://doi.org/10.1016/j.addma.2021.102287

M. Sadaf, M. Bragaglia, and F. Nanni, "A simple route for additive manufacturing of 316L stainless steel via Fused filament fabrication," Journal of Manufacturing Processes, vol. 67, pp. 141-150, 2021. DOI: https://doi.org/10.1016/j.jmapro.2021.04.055

D. Jiang and F. Ning, "Additive manufacturing of 316L stainless steel by a printing-debinding-sintering method: effects of microstructure on fatigue property," Journal of Manufacturing Science and Engineering, pp. 1-30, 2021. DOI: https://doi.org/10.1115/1.4050190

M.-W. Wu, Z.-K. Huang, C.-F. Tseng, and K.-S. Hwang, "Microstructures, mechanical properties, and fracture behaviors of metal-injection molded 17-4PH stainless steel," Metals and Materials International, vol. 21, no. 3, pp. 531-537, 2015. DOI: https://doi.org/10.1007/s12540-015-4369-y

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2024 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.