The effects of the crystallinity index of cellulose on the flexural properties of hybrid-cellulose epoxy composites

DOI:

https://doi.org/10.55713/jmmm.v34i3.1902คำสำคัญ:

Crystallinity index, Hybrid-cellulose epoxy composite, Flexural properties, Interfacial bondingบทคัดย่อ

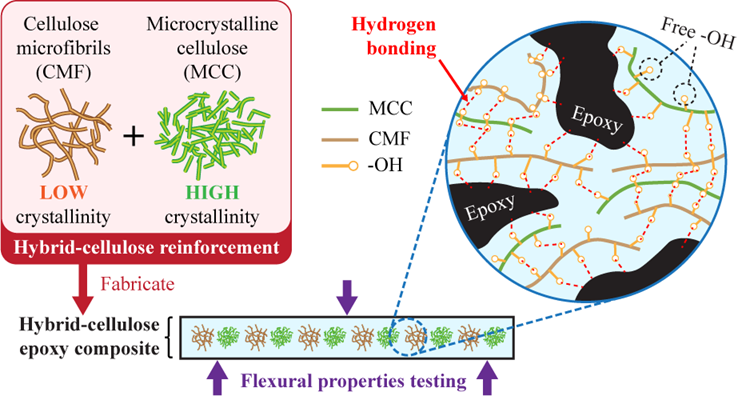

This work investigated the effects of the crystallinity index (CI) of cellulose on the flexural properties of hybrid-cellulose epoxy composites. The CI was varied by combining cellulose microfibrils (CMF) and microcrystalline cellulose (MCC), extracted from coir and eucalyptus, respectively, in various mixing ratios. From the XRD analysis, it was shown that the CI values and the CMF/MCC content follow a parabolic-fitting pattern, reaching a maximum value of 82.06% for the CMF/MCC of 30/70. The composites with cellulose of different CI values were fabricated and the flexural properties were measured. The results showed that the flexural strength increased as the CI increased, reaching a maximum of 105.45 MPa for a CI value of 81.87%. However, the flexural modulus displayed a parabolic relationship with respect to the CI value, reaching a maximum of 3,015.53 MPa for a CI value of 81.45%. FTIR spectroscopy was used to study the correlation between the interfacial bonding via hydrogen bonding of hydroxyl groups in cellulose and epoxy, the CI value, and the flexural properties. It was suggested that the strength of the cellulose was an important factor for the flexural strength of the composite, whereas both cellulose strength and interfacial bonding were crucial for the enhancement of the flexural modulus.

Downloads

เอกสารอ้างอิง

S. S. Godara, A. Yadav, B. Goswami, and R. S. Rana, “Review on history and characterization of polymer composite materials,” Materials Today: Proceedings, vol. 44, pp. 2674-2677, 2021. DOI: https://doi.org/10.1016/j.matpr.2020.12.680

C. Wu, F. Xu, H. Wang, H. Liu, F. Yan, and C. Ma, “Manufacturing technologies of polymer composites-A review,” Polymers (Basel), vol. 15, no. 3, p. 712, 2023. DOI: https://doi.org/10.3390/polym15030712

K. K. Chawla, “Introduction,” in Composite Materials: Science and Engineering, K. K. Chawla Ed. Cham: Springer International Publishing, 2019, pp. 3-6. DOI: https://doi.org/10.1007/978-3-030-28983-6_1

M. Z. Rong, M. Q. Zhang, Y. Liu, G. C. Yang, and H. M. Zeng, “The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites,” Composites Science and Technology, vol. 61, no. 10, pp. 1437-1447, 2001. DOI: https://doi.org/10.1016/S0266-3538(01)00046-X

M. R. Vignon, L. Heux, M. E. Malainine, and M. Mahrouz, “Arabinan–cellulose composite in Opuntia ficus-indica prickly pear spines,” Carbohydrate Research, vol. 339, no. 1, pp. 123-131, 2004. DOI: https://doi.org/10.1016/j.carres.2003.09.023

A. K. Bledzki, S. Reihmane, and J. Gassan, “Properties and modification methods for vegetable fibers for natural fiber composites,” Journal of Applied Polymer Science, vol. 59, no. 8, pp. 1329-1336, 1996. DOI: https://doi.org/10.1002/(SICI)1097-4628(19960222)59:8<1329::AID-APP17>3.0.CO;2-0

K. G. Satyanarayana, K. Sukumaran, P. S. Mukherjee, C. Pavithran, and S. G. K. Pillai, “Natural fibre-polymer composites,” Cement and Concrete Composites, vol. 12, no. 2, pp. 117-136, 1990. DOI: https://doi.org/10.1016/0958-9465(90)90049-4

A. Bismarck, S. Mishra, and T. Lampke, “Plant fibers as reinforcement for green composites,” in Natural Fibers, Biopolymers, and Biocomposites, A. K. Mohanty, M. Misra, and L. T. Drzal Eds. Boca Raton: CRC Press, 2005, pp. 37-108. DOI: https://doi.org/10.1201/9780203508206.ch2

W. Thammawichai, N. Poopakdee, C. Suwanchawalit, and K. Suwatpipat, “Synthesis and characterization of cellulose-microfibril reinforced epoxy composite,” in 2015 Asian Conference on Defence Technology (ACDT), pp. 180-182. DOI: https://doi.org/10.1109/ACDT.2015.7111607

M. M. Thwe and K. Liao, “Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites,” Composites Science and Technology, vol. 63, no. 3, pp. 375-387, 2003. DOI: https://doi.org/10.1016/S0266-3538(02)00225-7

A. R. Bhat, R. Kumar, and P. K. S. Mural, “Natural fiber reinforced polymer composites: A comprehensive review of Tribo‐Mechanical properties,” Tribology International, vol. 189, p. 108978, 2023. DOI: https://doi.org/10.1016/j.triboint.2023.108978

R. A. Kurien, M. Maria Anil, S. L. Sharan Mohan, and J. Anna Thomas, “Natural fiber composites as sustainable resources for emerging applications- a review,” Materials Today: Proceedings, 2023. DOI: https://doi.org/10.1016/j.matpr.2023.04.363

L. Chen, Z. Chen, Z. Xie, L. Wei, J. Hua, L. Huang, and P.-S. Yap, “Recent developments on natural fiber concrete: A review of properties, sustainability, applications, barriers, and opportunities,” Developments in the Built Environment, p. 100255, 2023. DOI: https://doi.org/10.1016/j.dibe.2023.100255

I. Elfaleh, F. Abbassi, M. Habibi, F. Ahmad, M. Guedri, M. Nasri, and C. Garnier, “A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials,” Results in Engineering, vol. 19, p. 101271, 2023. DOI: https://doi.org/10.1016/j.rineng.2023.101271

P. M. Visakh and S. Thomas, “Preparation of bionanomaterials and their polymer nanocomposites from waste and biomass,” Waste and Biomass Valorization, vol. 1, no. 1, pp. 121-134, 2010. DOI: https://doi.org/10.1007/s12649-010-9009-7

J. R. Collier, M. Lu, M. Fahrurrozi, and B. J. Collier, “Cellulosic reinforcement in reactive composite systems,” Journal of Applied Polymer Science, vol. 61, no. 8, pp. 1423-1430, 1996. DOI: https://doi.org/10.1002/(SICI)1097-4628(19960822)61:8<1423::AID-APP24>3.0.CO;2-Y

I. Aranberri-Askargorta, T. Lampke, and A. Bismarck, “Wetting behavior of flax fibers as reinforcement for polypropylene,” Journal of Colloid and Interface Science, vol. 263, no. 2, pp. 580-589, 2003. DOI: https://doi.org/10.1016/S0021-9797(03)00294-7

N. Rehman, Alam, N. Amin, I. Mian, and H. Ullah, “Ecofriendly isolation of cellulose from eucalyptus lenceolata : A novel approach,” International Journal of Polymer Science, vol. 2018, pp. 1-7, 2018. DOI: https://doi.org/10.1155/2018/8381501

S. Kuga and R. Malcolm Brown, “Silver labeling of the reducing ends of bacterial cellulose,” Carbohydrate Research, vol. 180, no. 2, pp. 345-350, 1988. DOI: https://doi.org/10.1016/0008-6215(88)80091-0

N. Abzan, A. Abbasian, M. Jonoobi, and I. Ghasemi, “Cellulose microfiber extraction from leftover celery pulp: Chemomechanical treatments, structural, morphological, and thermal characterization,” International Journal of Biological Macromolecules, vol. 253, p. 126834, 2023. DOI: https://doi.org/10.1016/j.ijbiomac.2023.126834

R. L. Crawford, Lignin biodegradation and transformation. New York: John Wiley & Sons Inc, 1981, p. 170.

K. K. Chawla, “Interfaces,” in Composite Materials: Science and Engineering, K. K. Chawla Ed. Cham: Springer International Publishing, 2019, pp. 107-136. DOI: https://doi.org/10.1007/978-3-030-28983-6_4

K. Tashiro and M. Kobayashi, “Lattice-dynamical prediction of the limiting Young’s modulus of liquid crystalline arylate polymers: comparison with typical rigid-rod polymers,” Polymer, vol. 32, no. 3, pp. 454-463, 1991. DOI: https://doi.org/10.1016/0032-3861(91)90449-S

M. Grunert and W. T. Winter, “Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals,” Journal of Polymers and the Environment, vol. 10, no. 1, pp. 27-30, 2002. DOI: https://doi.org/10.1023/A:1021065905986

M. A. S. Azizi Samir, F. Alloin, and A. Dufresne, “Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field,” Biomacromolecules, vol. 6, no. 2, pp. 612-626, 2005. DOI: https://doi.org/10.1021/bm0493685

A. K. Bledzki and J. Gassan, “Composites reinforced with cellulose based fibres,” Progress in Polymer Science, vol. 24, no. 2, pp. 221-274, 1999. DOI: https://doi.org/10.1016/S0079-6700(98)00018-5

P. V. Joseph, K. Joseph, and S. Thomas, “Short sisal fiber reinforced polypropylene composites: The role of interface modification on ultimate properties,” Composite Interfaces, vol. 9, no. 2, pp. 171-205, 2002. DOI: https://doi.org/10.1163/156855402760116094

A. Amash, and P. Zugenmaier, “Morphology and properties of isotropic and oriented samples of cellulose fibre–polypropylene composites,” Polymer, vol. 41, no. 4, pp. 1589-1596, 2000. DOI: https://doi.org/10.1016/S0032-3861(99)00273-6

S. Dumitriu and E. Chornet, “Polysaccharides as support for enzyme and cell immobilization,” Polysaccharides, pp. 629-748, 1998.

W. Qiu, T. Endo, and T. Hirotsu, “Interfacial interactions of a novel mechanochemical composite of cellulose with maleated polypropylene,” Journal of Applied Polymer Science, vol. 94, no. 3, pp. 1326-1335, 2004. DOI: https://doi.org/10.1002/app.21123

Z. Ling, T. Wang, M. Makarem, M. Santiago Cintrón, H. N. Cheng, X. Kang, M. Bacher, A. Potthast, T. Rosenau, H. King, C. D. Delhom, S. Nam, J. Vincent Edwards, S. H. Kim, F. Xu, and A. D. French, “Effects of ball milling on the structure of cotton cellulose,” Cellulose, vol. 26, no. 1, pp. 305-328, 2019. DOI: https://doi.org/10.1007/s10570-018-02230-x

T. Huang, I. Kwan, K. D. Li, and M. Ek, “Effect of cellulose oxalate as cellulosic reinforcement in ternary composites of polypropylene/maleated polypropylene/cellulose,” Composites Part A: Applied Science and Manufacturing, vol. 134, p. 105894, 2020. DOI: https://doi.org/10.1016/j.compositesa.2020.105894

M. L. Nelson and R. T. O’Connor, “Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part II. A new infrared ratio for estimation of crystallinity in celluloses I and II,” Journal of Applied Polymer Science, vol. 8, no. 3, pp. 1325-1341, 1964. DOI: https://doi.org/10.1002/app.1964.070080323

Q. Wu, M. Henriksson, X. Liu, and L. A. Berglund, “A high strength nanocomposite based on microcrystalline cellulose and polyurethane,” Biomacromolecules, vol. 8, no. 12, pp. 3687-3692, 2007. DOI: https://doi.org/10.1021/bm701061t

A. Ashori, and A. Nourbakhsh, “Performance properties of microcrystalline cellulose as a reinforcing agent in wood plastic composites,” Composites Part B: Engineering, vol. 41, no. 7, pp. 578-581, 2010. DOI: https://doi.org/10.1016/j.compositesb.2010.05.004

N. Poopakdee and W. Thammawichai, “Fabrication and mechanical properties of multi-walled carbon nanotube and cellulose microfibril reinforced epoxy composite,” International Journal of Mechanical and Production Engineering (IJMPE), vol. 7, no. 12, pp. 39-43, 2019.

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials, ASTM D790, 2017.

L. Y. Mwaikambo, and M. P. Ansell, “Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization,” Journal of Applied Polymer Science, vol. 84, no. 12, pp. 2222-2234, 2002. DOI: https://doi.org/10.1002/app.10460

S. Park, J. O. Baker, M. E. Himmel, P. A. Parilla, and D. K. Johnson, “Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance,” Bio-technology for Biofuels, vol. 3, no. 1, p. 10, 2010. DOI: https://doi.org/10.1186/1754-6834-3-10

H. Yang, R. Yan, H. Chen, D. H. Lee, and C. Zheng, “Characteristics of hemicellulose, cellulose and lignin pyrolysis,” Fuel, vol. 86, no. 12, pp. 1781-1788, 2007. DOI: https://doi.org/10.1016/j.fuel.2006.12.013

V. A. Alvarez, and A. Vázquez, “Influence of fiber chemical modification procedure on the mechanical properties and water absorption of MaterBi-Y/sisal fiber composites,” Composites Part A: Applied Science and Manufacturing, vol. 37, no. 10, pp. 1672-1680, 2006. DOI: https://doi.org/10.1016/j.compositesa.2005.10.005

R. Javier-Astete, J. Jimenez-Davalos, and G. Zolla, “Determination of hemicellulose, cellulose, holocellulose and lignin content using FTIR in Calycophyllum spruceanum (Benth.) K. Schum. and Guazuma crinita Lam,” PLOS ONE, vol. 16, no. 10, p. e0256559, 2021. DOI: https://doi.org/10.1371/journal.pone.0256559

A. M. Raspolli Galletti, A. D’Alessio, D. Licursi, C. Antonetti, G. Valentini, A. Galia, and N. Nassi o Di Nasso, “Midinfrared FT-IR as a tool for monitoring herbaceous biomass composition and its conversion to furfural,” Journal of Spectroscopy, vol. 2015, p. 719042, 2015. DOI: https://doi.org/10.1155/2015/719042

L. Chen, J. Y. Zhu, C. Baez, P. Kitin, and T. Elder, “Highly thermal-stable and functional cellulose nanocrystals and nanofibrils produced using fully recyclable organic acids,” Green Chemistry, vol. 18, no. 13, pp. 3835-3843, 2016. DOI: https://doi.org/10.1039/C6GC00687F

Adapa, L. Tabil, G. J. Schoenau, T. Canam, and T. Dumonceaux, “Quantitative analysis of lignocellulosic components of non-treated and steam exploded Barley, Canola, Oat and wheat straw using Fourier Transform Infrared Spectroscopy,” Journal of Agricultural Science and Technology, vol. B1, pp. 177-188, 2011.

P. J. Herrera-Franco and A. Valadez-González, “A study of the mechanical properties of short natural-fiber reinforced composites,” Composites Part B: Engineering, vol. 36, no. 8, pp. 597-608, 2005. DOI: https://doi.org/10.1016/j.compositesb.2005.04.001

E. Abraham, B. Deepa, L. A. Pothan, M. Jacob, S. Thomas, U. Cvelbar, and R. Anandjiwala, “Extraction of nanocellulose fibrils from lignocellulosic fibres: A novel approach,” Carbohydrate Polymers, vol. 86, no. 4, pp. 1468-1475, 2011. DOI: https://doi.org/10.1016/j.carbpol.2011.06.034

A. Šturcová, G. R. Davies, and S. J. Eichhorn, “Elastic modulus and stress-transfer properties of tunicate cellulose whiskers,” Biomacromolecules, vol. 6, no. 2, pp. 1055-1061, 2005. DOI: https://doi.org/10.1021/bm049291k

Y. Habibi, L. A. Lucia, and O. J. Rojas, “Cellulose nanocrystals: Chemistry, self-assembly, and applications,” Chemical Reviews, vol. 110, no. 6, pp. 3479-3500, 2010. DOI: https://doi.org/10.1021/cr900339w

S. Cichosz and A. Masek, “IR study on cellulose with the varied moisture contents: Insight into the supramolecular structure,” Materials, vol. 13, no. 20, 2020. DOI: https://doi.org/10.3390/ma13204573

S. Y. Oh, D. I. Yoo, Y. Shin, and G. Seo, “FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide,” Carbohydrate Research, vol. 340, no. 3, pp. 417-428, 2005. DOI: https://doi.org/10.1016/j.carres.2004.11.027

E. Abraham, B. Deepa, L. A. Pothen, J. Cintil, S. Thomas, M. J. John, R. Anandjiwala, and S. S. Narine, “Environmental friendly method for the extraction of coir fibre and isolation of nanofibre,” Carbohydrate Polymers, vol. 92, no. 2, pp. 1477-1483, 2013. DOI: https://doi.org/10.1016/j.carbpol.2012.10.056

M. G. Pineda-Pimentel, N. Flores-Ramirez, J. C. Farias Sanchez, L. Domratcheva-Lvova, S. R. Vasquez-Garcia, and L. Garcia-Gonzalez, “Theoretical analysis and FTIR of cellulose nano-whiskers/Poly(ButylAcrylate),” Superficies y Vacío, vol. 29, no. 3, pp. 83-86, 2016.

Y. Nishiyama, “Structure and properties of the cellulose microfibril,” Journal of Wood Science, vol. 55, no. 4, pp. 241-249, 2009. DOI: https://doi.org/10.1007/s10086-009-1029-1

Y. Zheng, Z. Fu, D. Li, and M. Wu, “Effects of ball milling processes on the microstructure and rheological properties of microcrystalline cellulose as a sustainable polymer additive,” Materials, vol. 11, no. 7, 2018. DOI: https://doi.org/10.3390/ma11071057

Z. Liao, Z. Huang, H. Hu, Y. Zhang, and Y. Tan, “Microscopic structure and properties changes of cassava stillage residue pretreated by mechanical activation,” Bioresource Technology, vol. 102, no. 17, pp. 7953-7958, 2011. DOI: https://doi.org/10.1016/j.biortech.2011.05.067

S. Dmitro, S. Sergey, B. Valerii, Y. Olha, R. Maria, S. Alexandra, and L. Y. Kokhtych, “Resistance and strength of bio-compatible epoxy- cellulose composites, as a function of concentration and dispersity of cellulose filler,” Biomedical Journal of Scientific & Technical Research, vol. 31, no. 3, pp. 24211-24218, 2020. DOI: https://doi.org/10.26717/BJSTR.2020.31.005103

S. Nakamura, Y. Tsuji, and K. Yoshizawa, “Role of hydrogen-bonding and OH−π interactions in the adhesion of epoxy resin on hydrophilic surfaces,” ACS Omega, vol. 5, no. 40, pp. 26211-26219, 2020. DOI: https://doi.org/10.1021/acsomega.0c03798

W. Qiu, F. Zhang, T. Endo, and T. Hirotsu, “Milling-induced esterification between cellulose and maleated polypropylene,” Journal of Applied Polymer Science, vol. 91, no. 3, pp. 1703-1709, 2004. DOI: https://doi.org/10.1002/app.13368

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2024 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.