The influence of water-cement ratios and alumino-silicate based accelerator on the properties of fiber-reinforced cement composites

DOI:

https://doi.org/10.55713/jmmm.v33i2.1633Keywords:

fiber cement, air curing, autoclave curing, chemical admixture, water-cement ratioAbstract

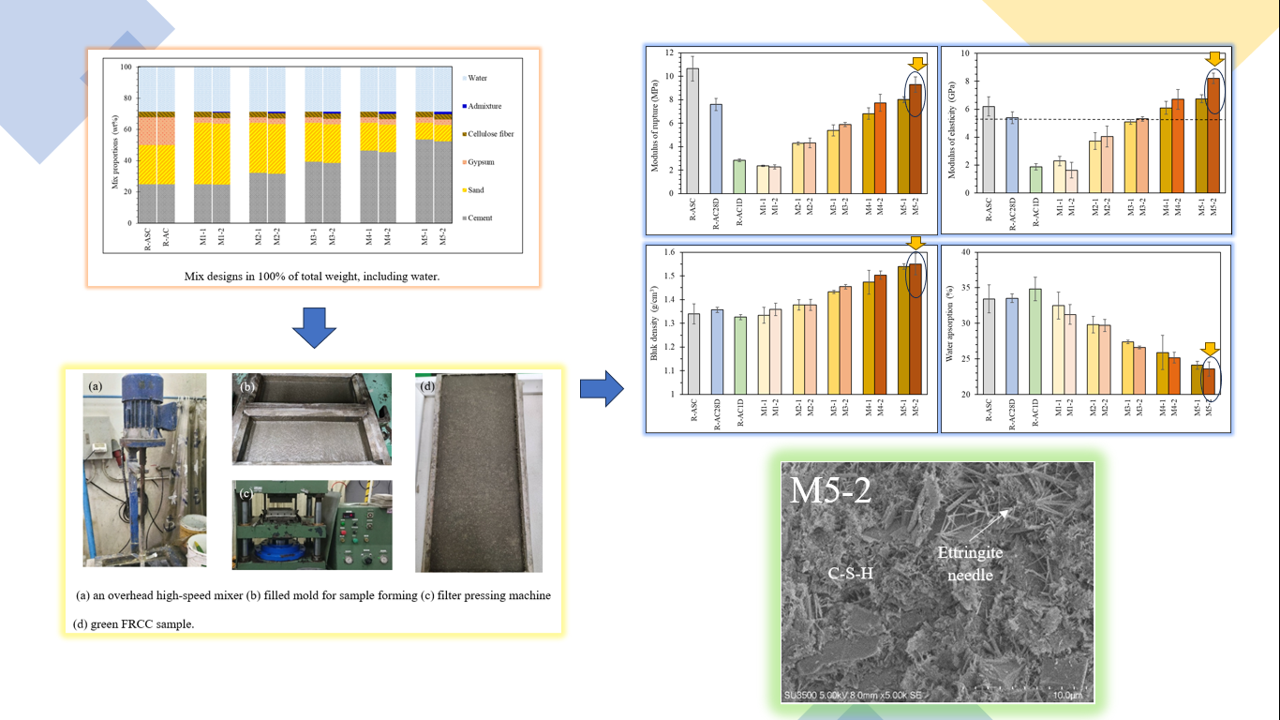

Due to more strict environmental protection and greenhouse gas reduction, it is very important for all industries to appropriately manage their energy consumption. Fiber- reinforced cement composites are the popular building materials which consume enormous energy to intensify its chemical reaction during the autoclave steam curing process. Utilization of chemical admixture to replace the conventional energy-driven autoclave steam curing process will support the fiber- reinforced cement composites industry to develop sustainable building materials. In this research, typical and mechanical properties of the air-cured fiber- reinforced cement composites incorporated with alumino-silicate based accelerator were investigated. The results show an excellent correlation between the water-cement ratio of the mix design and the mechanical strength which is the optimum water-cement ratio for this FRCC are 0.53. Moreover, the properties of fiber- reinforced cement composites cured by either the autoclave steam curing process or air-curing process are comparable.

Downloads

References

P. S. Intelligence. "Fiber cement market report: By raw material (portland cement, silica, cellulosic fiber), application (siding, roofing, cladding, molding and trimming), end user (residential, non-residential) – global industry analysis and growth forecast to 2030." https://www.psmarketresearch.com/

market-analysis/fiber-cement-market (accessed May 2022).

P. Chakartnarodom, N. Kongkajun, N. Chuankrerkkul, P. Ineure, and A. W. Prakaypan, "Reducing water absorption of fiber-cement composites for exterior applications by crystal modification method," Journal of Metals, Materials and Minerals, Article vol. 29, no. 4, pp. 90-98, 2019.

P. Chakartnarodom, W. Prakaypan, P. Ineure, N. Kongkajun, and N. Chuankrerkkul. Feasibility study of using basalt fibers as the reinforcement phase in fiber-cement products, Key Engineering Materials, vol. 766 KEM, pp. 252-257, 2018.

P. Pahuswanno, P. Chakartnarodom, N. Kongkajun, and W. Prakaypan. Feasibility study of using modified recycled fiber-cement for the production of high performance fiber-cement composites, Solid State Phenomena, vol. 302 SSP, pp. 93-99, 2020.

P. Sonprasarn, P. Chakartnarodom, N. Kongkajun, and W. Prakaypan. Microstructure and mechanical performance of fiber-reinforced cement composites made with nucleating-agent activated coal-fired power plant bottom ash, Solid State Phenomena, vol. 302 SSP, pp. 85-92, 2020.

P. Chakartnarodom, W. Prakaypan, P. Ineure, N. Chuankrerkkul, E. A. Laitila, and N. Kongkajun, "Properties and performance of the basalt-fiber reinforced texture roof tiles," Case Studies in Construction Materials, vol. 13, p. e00444, 2020.

B. Kottititum, Q. T. Phung, N. Maes, W. Prakaypan, and T. Srinophakun, "Early age carbonation of fiber-cement composites under real processing conditions: A parametric investigation," Applied Sciences, vol. 8, no. 2, 2018.

P. Chakartnarodom, S. Wanpen, W. Prakaypan, E. A. Laitila, and N. Kongkajun, "Development of high-performance fiber cement: A case study in the integration of circular economy in product design," Sustainability, vol. 14, no. 19, 2022.

L. Wang, H. Q. Yang, S. H. Zhou, E. Chen, and S. W. Tang, "Hydration, mechanical property and C-S-H structure of early-strength low-heat cement-based materials," Materials Letters, vol. 217, pp. 151-154, 2018.

Z. Zhang, Y. Yan, Z. Qu, and G. Geng, "Endowing strength to calcium silicate hydrate (C-S-H) powder by high pressure mechanical compaction," Cement and Concrete Research, vol. 159, p. 106858, 2022.

X. Ma, Z. Mei, and P. Ma, "Influence of water to cement ratio on mechanical performance of concrete canvas reinforced with warp-knitted spacer fabric," Geotextiles and Geomembranes, vol. 50, no. 4, pp. 708-719, 2022.

N. P. Mailvaganam, M. R. Rixom, D. P. Manson, and C. Gonzales, (1999). Chemical Admixtures for Concrete (3rd ed.). CRC Press. https://doi.org/10.4324/9780203017241

P. Sonprasarn, W. Prakaypan, S. Polsilapa, N. Kongkajun, E. A. Laitila, N. Chuankrerkkul, and P. Chakartnarodom, "The Influence of different crystal modifiers on ultra-low embodied energy curing fiber-reinforced cement composites," Journal of Metals, Materials and Minerals, vol. 32, no. 3, pp. 93-100, 2022.

ASTM C1185 Standard Test Methods for Sampling and Testing Non-Asbestos Fiber-Cement Flat Sheet, Roofing and Siding Shingles, and Clapboards, ASTM International, West Conshohocken, PA, USA, 2016.

ASTM C948-81 Standard Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete, ASTM International, West Conshohocken, PA, USA, 2016.

P. Sonprasarn, P. Chakartnarodom, N. Kongkajun, and W. Prakaypan, "Microstructure and mechanical performance of fiber-reinforced cement composites made with nucleating-agent activated coal-fired power plant bottom ash," Solid State Phenomena, vol. 302, pp. 85-92, 2020.

B. Kondraivendhan, and B. Bhattacharjee, "Strength and w/c ratio relationship of cement based materials through pore features," Materials Characterization, vol. 122, pp. 124-129, 2016.

S. B. Singh, P. Munjal, and N. Thammishetti, "Role of water/ cement ratio on strength development of cement mortar," Journal of Building Engineering, vol. 4, pp. 94-100, 2015.

Z. Lu, J. Lu, Z. Liu, Z. Sun, and D. Stephan, "Influence of water to cement ratio on the compatibility of polycarboxylate superplasticizer with Portland cement," Construction and Building Materials, vol. 341, p. 127846, 2022.

P. C. Hewlett, H. Justnes, and R. M. Edmeades, "14 - cement and concrete admixtures," in Lea's Chemistry of Cement and Concrete (Fifth Edition), P. C. Hewlett and M. Liska Eds.: Butterworth-Heinemann, 2019, pp. 641-698.

P.-C. Aïtcin, "17 - The Influence of the water/cement ratio on the sustainability of concrete," in Lea's Chemistry of Cement and Concrete (Fifth Edition), P. C. Hewlett and M. Liska Eds.: Butterworth-Heinemann, 2019, pp. 807-826.

P. Wang, L.-y.-w. Ke, H.-l. Wu, and C. K. Y. Leung, "Effects of water-to-cement ratio on the performance of concrete and embedded GFRP reinforcement," Construction and Building Materials, vol. 351, p. 128833, 2022.

Y. K. Cho, S. H. Jung, and Y. C. Choi, "Effects of chemical composition of fly ash on compressive strength of fly ash cement mortar," Construction and Building Materials, vol. 204, pp. 255-264, 2019.

P. Sonprasarn, P. Chakartnarodo, P. Ineure, and W. Prakaypan, "Effects of the chemical treatment on coal-fired bottom ash for the utilization in fiber-reinforced cement composites," Journal of Metals, Materials and Minerals, vol. 29, no. 4, 2019.

J. Du, W. Meng, K. H. Khayat, Y. Bao, P. Guo, Z. Lyu, A. A. Obeidah, H. Nassif, and H. Wang, "New development of ultra-high-performance concrete (UHPC)," Composites Part B: Engineering, vol. 224, p. 109220, 2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.