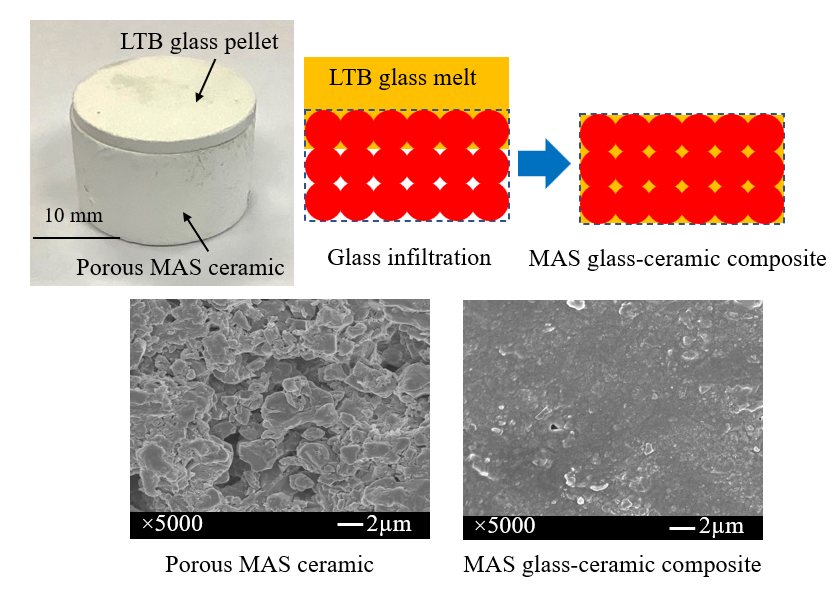

Fabrication of glass-ceramics composite by infiltration of lithium tetraborate glass into porous magnesium aluminate spinel ceramic

DOI:

https://doi.org/10.55713/jmmm.v33i1.1614Keywords:

Glass-ceramics composite, glass infiltration, lithium tetraborate glass, magnesium aluminate spinel, porousAbstract

Magnesium aluminate spinel (MAS) glass-ceramics composite has excellent mechanical and optical properties. It can be obtained from porous ceramic by infiltrating the proper choice of glass. In this study, porous MAS ceramic was prepared by conventional sintering from MAS powder to reach a bulk density of 2.48 g∙cm-3 (70.1% of relative density). The porous MAS ceramic was then infiltrated with molten lithium tetraborate glass (Li2B4O7; LTB) at 950℃ for 30 (IF30) and 60 (IF60) min. They were left to cool down to 700℃ inside the furnace before being taken out to quench in ambient. The glass-ceramics composite was obtained with 98.7% and 92.1% relative density for IF30 and IF60 cases, respectively. SEM images reveal a lower degree of porosity in the IF30 case, which achieves higher flexural strength of 119.7 MPa. X-ray diffraction and Raman spectroscopy indicate that Mg2B2O5 phase (at 2q =35°) and B2O5 functional group (at 847 cm-1) are formed during infiltration. Consequently, their micro vickers hardness increased (3.41®5.53®6.16 GPa).

Downloads

References

P. Biswas, R. Johnson, Y. R. Mahajan, and G. Padmanabham, “Processing of infrared transparent magnesium aluminate spinel: an overview,” Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications, pp. 495-531, 2020.

A. Goldstein, and A. Krell, “Transparent ceramics at 50: Progress made and further prospects,” Journal of the American Ceramic Society, vol. 99, no. 10, 3173-3197, 2016.

I. Ganesh, “A review on magnesium aluminate (MgAl2O4) spinel: synthesis, processing and applications,” International Materials Reviews, vol. 58, no. 2, pp. 63-112, 2013.

D. C. Harris, L. Johnson, R. Seaver, T. Lewis, G. Turri, M. Bass, and N.D. Haynes, “Optical and thermal properties of spinel with revised (increased) absorption at 4 to 5 μm wavelengths and comparison with sapphire,” Optical Engineering, vol. 52, no. 8, pp. 087113-087113, 2013.

T. J. Mroz, T. M. Hartnett, J. M. Wahl, L. M. Goldman, J. Kirsch, and W. R. Lindberg, “Recent advances in spinel optical ceramic,” In Window and Dome Technologies and Materials IX, International Society for Optics and Photonics, pp. 64-70, 2005.

R. Sarkar, and S. Sahoo. “Effect of raw materials on formation and densification of magnesium aluminate spinel,” Ceramics International, vol. 40, no. 10, pp. 16719-16725, 2014.

K. Morita, B. N. Kim, H. Yoshida, and K. Hiraga, “Densification behaviour of a fine-grained MgAl2O4 spinel during spark plasma sintering (SPS),” Scripta Materialia63, vol. 6, pp. 565-568, 2010.

D. S. Tsai, C. T. Wang, S. J. Yang, and A. S. Hsu, “Hot isostatic pressing of MgAl2O4 spinel infrared windows,” Material and manufacturing process, vol. 9, no. 4, pp. 709-719, 1994.

P. C. da Silva, R. de Oliveira Magnago, F. de Assis Baiao Miranda Pereira, K. Strecker, B. Galvao Simba, and C. dos Santos, “Magnesium aluminate spinel ceramics infiltrated with lanthanum-glass for dental applications,” International Journal of Materials Research, vol. 110, no. 9, pp. 885-891, 2019.

R. D. O. Magnago, F. D. A. B. Miranda Pereira, P. C. da Silva, J. V. C. de Souza, and C. dos Santos, “Infiltrated spinel-based ceramic (MgAl2O4) for dental application,” Materials Science Forum, Trans Tech Publications, vol. 881, 2017.

D. Kumar, A. Moharana, and A. Kumar, “Current trends in spinel based modified polymer composite materials for electro-magnetic shielding,” Materials Today Chemistry, vol. 17, p. 100346, 2020.

E. Elhomiamy, Y. Aboushady, and B. El Malakh, “Wear behaviour and surface roughness of polymer infiltrated ceramic material compared to pressable glass-ceramic,” Alexandria Dental Journal, vol. 40, no. 1, pp. 65-70, 2015.

P. Magne, and U. Belser. “Esthetic improvements and in vitro testing of In-Ceram Alumina and Spinell ceramic,” International Journal of Prosthodontics, vol. 10, no. 5, 1997.

T. Jain, A. Porwal, B. R. Bangar, S. B. Randive, K.nP. Vaishnav, K. Walkar, and A. S. Nayyar, “Computer-aided design and computer-aided manufacturing ceramic biomaterials in dentistry: Past to present,” Journal of Dental and Allied Sciences, vol. 7, no. 1, p. 18, 2018.

M. Fradeani, A. Aquilano, and M. Corrado, “Clinical experience with in-ceram spinell crowns: 5-year follow-up,” International journal of periodontics & restorative dentistry, vol. 22, no. 6, 2002.

E. O. Einset. “Capillary infiltration rates into porous media with applications to silcomp processing,” Journal of the American Ceramic Society, vol. 79, no. 2, pp. 333-338, 1996.

D. Y. Lee, D. J. Kim, B. Y. Kim, and Y. S. Song, “Effect of alumina particle size and distribution on infiltration rate and fracture toughness of alumina–glass composites prepared by melt infiltration,” Materials Science and Engineering: A, vol. 341, no. 1-2, pp. 98-105, 2003.

S. Shi, Q. Zhang, H. Wang, and Y. Li, “La2O3–Al2O3–SiO2 glass-infiltrated 3Y-TZP all-ceramic composite for the dental restorative application”. Progress in Natural Science: Materials International, vol. 22, no. 3, pp. 224-230, 2012.

Z. Yang, Q. Jin, J. Ma, Y. Tong, X. Wang, R. Du, and S. Wang, “Glass infiltration of gel cast zirconia-toughened alumina ceramics for dental restoration,” Ceramics International, vol. 38, no. 6, pp. 4653-4659, 2012.

M. B. Berger, “The importance and testing of density/porosity/ permeability/pore size for refractories,” in The Southern African Institute of Mining and Metallurgy Refractories Conference, pp. 101-116, 2010.

D. D. L. Chung, “Polymer-matrix composites: Structure and processing,” Carbon Composites, pp. 161-217, 2017.

D. Yang, Y. Zhang, X. Song, Y. Chen, Z. Shen, and C. Yang, “Effects of sintering temperature and holding time on porosity and shrinkage of glass tubes,” Ceramics International, vol. 42, no. 5, pp. 5906-5910, 2016.

S. J. Lee, M. K. Waltraud, and H. M. Kim, “Shrinkage‐free, alumina–glass dental composites via aluminum oxidation,” Journal of the American Ceramic Society, vol. 80, no. 8, pp. 2141-2147, 1997.

V. Bougiouri, R. Voytovych, N. Rojo-Calderon, J. Narciso, and N. Eustathopoulos, “The role of the chemical reaction in the infiltration of porous carbon by NiSi alloys,” Scripta materialia, vol. 54, no. 11, pp. 1875-1878, 2006.

S. Wan, X. Tang, Y. Sun, G. Zhang, J. You, and P. Fu, “Raman spectroscopy and density functional theory analyses of the melt structure in a Li2B4O7 crystal growth system,” Cryst Eng Comm, vol. 16, no. 15, pp. 3086-3090, 2014.

N. Van Minh, and I. S. Yang. “A Raman study of the cation-disorder transition temperature of natural MgAl2O4 spinel,” Vibrational Spectroscopy, vol. 35, no. 1-2, pp. 93-96. 2004.

S. Li, D. Xu, H. Shen, J. Zhou, and Y. Fan, “Synthesis and Raman properties of magnesium borate micro/nanorods,” Materials Research Bulletin, vol. 47, no. 11, pp. 3650-3653, 2012.

A. K. Yadav, and P. Singh. “A review of the structures of oxide glasses by Raman spectroscopy,” RSC advances, vol. 5, no. 83, pp. 67583-67609, 2015.

J. Seuba, S. Deville, C. Guizard, and A.J. Stevenson, “Mechanical properties and failure behavior of unidirectional porous ceramics,” Scientific reports, no. 6, no. 1, pp. 1-11, 2016.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.