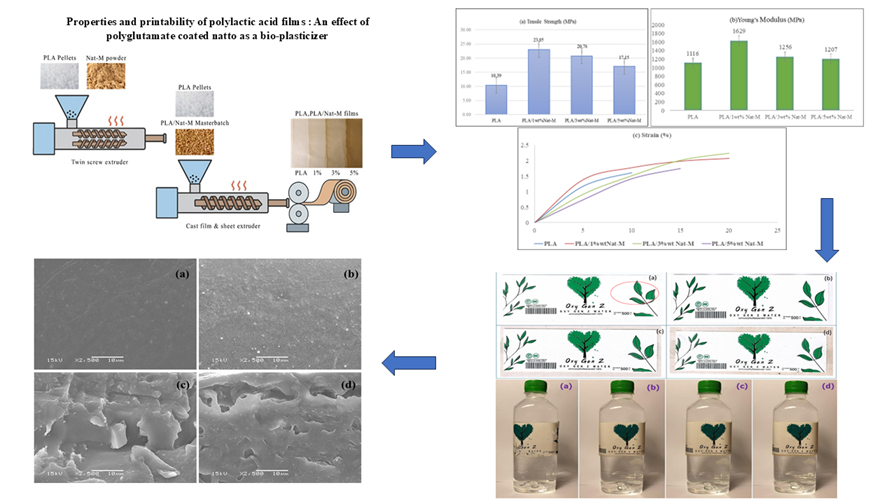

Properties and printability of polylactic acid films : An effect of polyglutamate coated natto as a bio-plasticizer

DOI:

https://doi.org/10.55713/jmmm.v36i1.2533คำสำคัญ:

Polylactic acid films, Polyglutamate coated natto, Bioplasticizer, Screen-printabilityบทคัดย่อ

Polylactic acid (PLA) film, a biodegradable alternative to petroleum-based plastics, has gained significant attention for sustainable packaging applications. However, its limited screen-printability remains a barrier to broader commercial use. This study aims to enhance the screen-printability of PLA film by incorporating a polyglutamate coated natto (designated as Nat-M). PLA/Nat-M films having 1%, 3%, and 5% Nat-M were prepared and evaluated for their key performance indicators, including ink adhesion (ASTM D3359), tone reproduction accuracy, and printing resolution. The screen-printing resolution was optimized between 400 DPI and 500 DPI (dots per inch) to achieve optimal tone reproduction and edge sharpness. Additionally, ink abrasion resistance and surface wettability were assessed by water contact angle (WCA) measurements. The results indicated that all PLA/Nat-M films exhibited improved screen-printing characteristics when compared to pristine PLA. These findings suggest that PLA/modified natto, particularly at 3% and 5% Nat-M loadings, provided a viable and environmentally friendly solution for improving the printability of biodegradable label.

Downloads

เอกสารอ้างอิง

L. K. Ncube, A. U. Ude, E. N. Ogunmuyiwa, R. Zulkifli, and I. N. Beas, “Environmental impact of food packaging materials: A review of contemporary development from conventional plastics to polylactic acid based materials,” Materials, vol. 13, no. 21, p. 4994, Nov. 2020. DOI: https://doi.org/10.3390/ma13214994

W. B. Kusumaningrum, F. A. Syamani, and L. Suryanegara, “Heat properties of polylactic acid biocomposites after addition of plasticizers and oil palm frond microfiber,” Jurnal Kimia Sains dan Aplikasi, vol. 23, no. 8, pp. 295–304, 2020. DOI: https://doi.org/10.14710/jksa.23.8.295-304

Y. H. Hu, Y. S. Hu, V. Topolkaraev, A. Hiltner, and E. Baer, “Crystallization and phase separation in blends of high stereo-regular poly(lactide) with poly(ethylene glycol),” Polymer, vol. 44, no. 19, pp. 5681–5689, 2003. DOI: https://doi.org/10.1016/S0032-3861(03)00609-8

Y. Xu, W. Yu, and C. Zhou, “Liquid–liquid phase separation and its effect on the crystallization in polylactic acid/poly(ethylene glycol) blends,” RSC Advances, vol. 4, no. 98, pp. 55435–55444, 2014. DOI: https://doi.org/10.1039/C4RA08985E

M. Kowalczyk, M. Pluta, E. Piorkowska, and N. Krasnikova, “Plasticization of polylactide with block copolymers of ethylene glycol and propylene glycol,” Journal of Applied Polymer Science, vol. 125, no. 6, pp. 4292–4300, 2012. DOI: https://doi.org/10.1002/app.36563

K. Okamoto, T. Ichikawa, T. Yokohara, and M. Yamaguchi, “Miscibility, mechanical and thermal properties of poly(lactic acid)/polyester-diol blends,” European Polymer Journal, vol. 45, no. 8, pp. 2304–2312, 2009. DOI: https://doi.org/10.1016/j.eurpolymj.2009.05.011

Z. Kulinski, E. Piorkowska, K. Gadzinowska, and M. Stasiak, “Plasticization of poly(L-lactide) with poly(propylene glycol),” Biomacromolecules, vol. 7, no. 7, pp. 2128–2135, 2006. DOI: https://doi.org/10.1021/bm060089m

G. Mu, L. Ren, and M. Zhang, “Sustainable composites from biodegradable PLA modified with isosorbide-based plasticizer,” Journal of Thermoplastic Composite Materials, vol. 38, no. 6, pp. 3781–3798, 2025. DOI: https://doi.org/10.1177/08927057251318717

M. Verma, B. D. Palanisamy, S. P. Singh, G. B. Reddy, D. Kavitake, and P. H. Shetty, “Microbial poly-glutamic acid: Production, biosynthesis, properties, and their applications in food, environment, and biomedicals,” Fermentation, vol. 11, no. 4, p. 208, 2025. DOI: https://doi.org/10.3390/fermentation11040208

M. Ashiuchi, S. Oike, H. Hakuba, S. Shibatani, N. Oka, and T. Wakamatsu, “Rapid purification and plasticization of d-glutamate-containing poly-γ-glutamate from Japanese fermented soybean food natto,” Journal of Pharmaceutical and Biomedical Analysis, vol. 116, pp. 90–93, 2015. DOI: https://doi.org/10.1016/j.jpba.2015.01.031

L. C. Johnson, A. T. Akinmola, and C. Scholz, “Poly(glutamic acid): From natto to drug delivery systems,” Biocatalysis and Agricultural Biotechnology, vol. 40, p. 102292, 2022. DOI: https://doi.org/10.1016/j.bcab.2022.102292

A. Ogunleye, A. Bhat, V. U. Irorere, D. Hill, C. Williams, and I. Radecka, “Poly-γ-glutamic acid: Production, properties and applications,” Microbiology, vol. 161, no. 1, pp. 1–17, 2015. DOI: https://doi.org/10.1099/mic.0.081448-0

M. Ataeefard, “Study of PLA printability with flexography ink: Comparison with common packaging polymer,” Progress in Color, Colorants and Coatings, vol. 12, no. 2, pp. 101–105, 2019.

M. Rentzhog, Characterisation of water-based flexographic inks and their interactions with polymer coated board, Licentiate thesis, Stockholm, Sweden, 2004.

S. Sun, Y. Weng, and C. Zhang, "Recent advancements in bio-based plasticizers for polylactic acid (PLA): A review," Polymer Testing, vol. 140, pp. 108603, 2024. DOI: https://doi.org/10.1016/j.polymertesting.2024.108603

A. Perez-Nakai, A. Lerma-Canto, I. Dominguez-Candela, D. Garcia-Garcia, J. M. Ferri, and V. Fombuena, “Comparative study of the properties of plasticized polylactic acid with maleinized hemp seed oil and a novel maleinized Brazil nut seed oil,” Polymers, vol. 13, no. 14, p. 2376, 2021. DOI: https://doi.org/10.3390/polym13142376

A. Perez-Nakai, A. Lerma-Canto, I. Dominguez-Candela, J. M. Ferri, and V. Fombuena, “Novel epoxidized Brazil nut oil as a promising plasticizing agent for PLA,” Polymers, vol. 15, no. 9, p. 1997, 2023. DOI: https://doi.org/10.3390/polym15091997

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2025 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.