Extraction of lutein dye from Tagetes erecta garland waste for green dyeing of hemp fabric using response surface methodology

DOI:

https://doi.org/10.55713/jmmm.v32i4.1527Keywords:

garland waste, hemp, Tagetes erecta, response surface methodology, marigoldAbstract

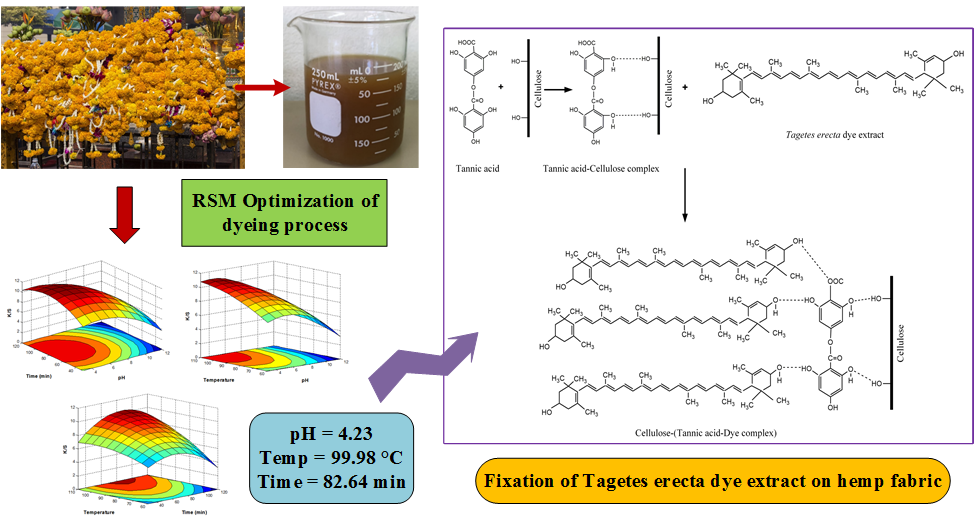

Large quantities of discarded flowers from religious observances are left at temples and other places of worship, causing global disposal and environmental issues. Recycling and transforming such organic waste into value-added products is one of the most effective and beneficial solutions to the problem. The main goal of this study is to convert the most abundant temple wastes of marigold (Tagetes erecta) flowers into an eco-friendly dyestuff for the textile industry. Our study assessed the suitability of dye extract from garland waste for dyeing hemp fabric and valuated indicators including color strength (K/S) and fastness properties using tannic acid as a bio-mordant. Response surface methodology (RSM) was used for optimization of the dyeing process and evaluation of the interaction effects of various operating parameters. The optimal conditions were determined to be pH of 4.23, dyeing temperature of 99.98°C, and dyeing time of 82.64 min. To validate the optimal conditions identified by RSM, performance evaluations were conducted, including color fastness properties of the dyed hemp fabrics as well as the total color difference after repeated standard washing. These results demonstrate the use of aqueous extract from temple garland waste combined with bio-mordant represents a promising approach for textile dyeing.

Downloads

References

M. Waghmode, A. Gunjal, N. Nawani, and N. Patil, “Management of floral waste by conversion to value-added products and their other applications,” Waste and Biomass Valorization, vol. 9, pp. 33-43, 2018.

S. Dutta, and M. S. Kumar, “Potential of value-added chemicals extracted from floral waste: A review,” Journal of Cleaner Production, vol. 294, pp. 126280, 2021.

G. Elango, and R. Govindasamy, “Analysis and utilization of temple waste flowers in coimbatore district,” Environmental Science and Pollution Research, vol. 25, pp. 10688-10700, 2018.

I. Wijaya, K. Ranwella, E. Revollo, L. Widhiasih, P. Putra, and P. Junanta, “Recycling temple waste into organic incense as temple environment preservation in bali Island,” Jurnal Ilmu Lingkungan, vol. 19, pp. 365-371, 2021.

K. Kalus, J. A. Koziel, and S. Opaliński, “A Review of biochar properties and their utilization in crop agriculture and livestock production,” Applied Sciences, vol. 9, p. 3494, 2019.

P. Singh, A. Borthakur, R. Singh, S. Awasthi, D. Pal, P. Srivastava, D. Tiwary, and P. Mishra, “Utilization of temple floral waste for extraction of valuable products: A close loop approach towards environmental sustainability and waste management,” Pollution, vol. 3, pp. 39-45, 2016.

J. B. N. Mudumbi, A. P. Daso, O. J. Okonkwo, S. K. O. Ntwampe, T. E. Matsha, , L. Mekuto, E. F. Itoba-Tombo, A. T. Adetunji, and L. L. Sibali, “Propensity of Tagetes erecta L., a medicinal plant commonly used in diabetes management, to accumulate perfluoroalkyl substances,” Toxics, vol. 7, no. 1, pp. 18, 2019.

W. Wang, H. Xu, H. Chen, K. Tai, F. Liu, and Y. Gao, “In vitro antioxidant, anti-diabetic and antilipemic potentials

of quercetagetin extracted from marigold (Tagetes erecta L.) inflorescence residues,” Journal of Food Science and Technology, vol. 53, no. 6, pp. 2614-2624, 2016.

U. Baig, A. Khatri, S. Shaikh, N. Sanbhal, F. Ishaque, and N. Junejo, “Ultrasound-assisted dyeing of cotton fabric with natural dye extracted from Marigold flower,” Journal of The Textile Institute, vol. 112, pp. 1-8, 2020.

S. Khattak, S. Rafique, T. Hussain, and A. Bashir, “Optimization of fastness and tensile properties of cotton fabric dyed with natural extracts of marigold flower (Tagetes erecta) by pad-steam method,” Life Science Journal, vol. 11, pp. 52-60, 2014.

M. Shabbir, R. Luqman, and F. Mohammad, “Economically viable UV-protective and antioxidant finishing of wool fabric dyed with Tagetes erecta flower extract: Valorization of marigold,” Industrial Crops and Products, vol. 119, pp. 277-282, 2018.

S. Adeel, T. Gulzar, M. Azeem, F. Rehman, M. Saeed, I. Hanif, and N. Iqbal, “Appraisal of marigold flower based lutein as natural colourant for textile dyeing under the influence of gamma radiations,” Radiation Physics and Chemistry, vol. 130, pp. 35-39, 2017.

M. Montazer, and M. P. Gashti, “Dyeing of wool with marigold and its properties,” Fibers and Polymers, vol. 8, no. 2, pp. 181-185, 2007.

J. Vastrad, L. Walmiki, and G. Goudar, “Dyeing of cotton yarn with marigold (Tagetes erecta) petals: An emphasis on pre-treatments and mordants,” Journal of Applied and Natural Science, vol. 9, pp. 1282-1286, 2017.

X. Yan, L. Hong, S. Pei, A. Hamilton, H. Sun, R. Yang, A. Liu, and L. Yang, “A natural yellow colorant from Buddleja officinalis for dyeing hemp fabric,” Industrial Crops and Products, vol. 171, pp. 113968, 2021.

M. Zuber, S. Adeel, F. Rehman, F. Anjum, M. Muneer, M. Abdullah, and K. M. Zia, “Influence of microwave radiation on dyeing of bio-mordanted silk fabric using neem bark (Azadirachta indica) based tannin natural dye,” Journal of Natural Fibers, vol. 13, no. 10, pp. 1410-1422, 2020.

K. Phan, E. Van Den Broeck, V. Van Speybroeck, K. De Clerck, K. Raes, and S. De Meester, “The potential of anthocyanins from blueberries as a natural dye for cotton: A combined experimental and theoretical study,” Dyes and Pigments, vol. 176, pp. 108180, 2020.

A. K. Das, M. N. Islam, M. O. Faruk, M. D. Ashaduzzaman, and R. Dungani, “Review on tannins: Extraction processes, applications and possibilities,” South African Journal of Botany, vol. 135, pp. 58-70, 2020.

H. Bacelo, S. Santos, and C. Botelho, “Tannin-based biosorbents for environmental applications-a review,” Chemical Engineering Journal, vol. 303, pp. 575-587, 2016.

G. Gumrukcu, and M. Özgür, “Effect of tannic acid and metal salts on dyeing of woolen fabrics with red onion (Alliumcepa L.),” Asian Journal of Chemistry, vol. 23, pp. 1459-1466, 2011.

Z. Wen, Z. Yang, R. Tang, J. Guan, and Y. Qiao, “Application of tannic acid and ferrous ion complex as eco-friendly flame retardant and antibacterial agents for silk,” Journal of Cleaner Production, vol. 250, pp. 119545, 2020.

A. Ali, S. Ali, H. Saleem, and T. Hussain, “Effect of tannic acid and metallic mordants on the dyeing properties of natural dye extracted from acacia nilotica bark,” Asian journal of chemistry, vol. 22, pp. 7065-7069, 2010.

K. Li, Q. Ding, and H. Zhang, “Eco-friendly dyeing of cotton fabric using natural dye from orange peel,” Journal of The Textile Institute, vol. 113, pp. 360-366, 2020.

G. E. P. Box and K. B. Wilson, “On the experimental attainment of optimum conditions,” Journal of the Royal Statistical Society. Series B (Methodological), vol. 13, no. 1, pp. 1-45, 1951.

C. Yu, Y. Lu, K. Tao, and Z. Xi, “Optimization of the cationizing condition in salt‐free reactive dyeing of cotton fabric with the pad‐irradiate‐pad‐steam process using response surface methodology,” Environmental Progress & Sustainable Energy, vol. 39, pp. 13341, 2019.

R. Mansour, B. Ezzili, and M. Farouk, “The use of response surface method to optimize the extraction of natural dye from winery waste in textile dyeing,” Journal of The Textile Institute, vol. 108, no. 4, pp. 528-537, 2017.

Y. Yin, J. Jia, T. Wang, and C. Wang, “Optimization of natural anthocyanin efficient extracting from purple sweet potato for silk fabric dyeing,” Journal of Cleaner Production, vol. 149, pp. 673-679, 2017.

I. Elksibi, W. Haddar, M. Ben Ticha, R. Gharbi, and M. F. Mhenni, “Development and optimisation of a non-conventional extraction process of natural dye from olive solid waste using response surface methodology (RSM),” Food Chemistry, vol. 161, pp. 345-352, 2014.

N. Baaka, A. Mahfoudhi, and M. F. Mhenni, “Tannin-rich natural dye extracted from kermes oak (Quercus coccifera L.): Process optimization using response surface methodology (RSM),” Journal of Natural Fibers, vol. 16, pp. 1209-1220, 2019.

M. Sadeghi-Kiakhani, A. R. Tehrani-Bagha, S. Safapour, S. Eshaghloo‑Galugah, and S.M. Etezad, “Ultrasound-assisted extraction of natural dyes from Hawthorn fruits for dyeing polyamide fabric and study its fastness, antimicrobial, and antioxidant properties,” Environment, Development and Sustainability, vol. 23, pp. 9163-9180, 2021.

A. Haji, and M. Rahimi, “RSM optimization of wool dyeing with berberis thunbergii DC leaves as a new source of natural dye,” Journal of Natural Fibers, vol. 19, no. 8, pp. 2785-2798, 2020.

K. Sinha, K. Aikat, P. Das, and S. Datta, “Dyeing of modified cotton fiber with natural Terminalia arjuna dye: Optimization of dyeing parameters using response surface methodology,” Environmental Progress & Sustainable Energy, vol. 35, pp. 719-728, 2016.

W. Haddar, M. Ben Ticha, A. Guesmi, F. Khoffi, and B. Durand, “A novel approach for a natural dyeing process of cotton fabric with Hibiscus mutabilis (Gulzuba): Process development and optimization using statistical analysis,” Journal of Cleaner Production, vol. 68, pp. 114-120, 2014.

H. Barani, and K. Rezaee, “Optimization of dyeing process using achillea pachycephala as a natural dye for wool fibers,” Chiang Mai Journal of Science, vol. 44, pp. 1548-1561, 2017.

A. G. D. Schumacher, S. Pequito, and J. Pazour, “Industrial hemp fiber: A sustainable and economical alternative to cotton,” Journal of Cleaner Production, vol. 268, p. 122180, 2020.

D. Meghna, D. and G. Akshaya, “Optimization and extraction of natural dye from tagetes erecta and dyeing of cotton and silk fabric using banana (Musa Sp.) Pseudo Stem Sap,” Journal of Natural Fibers, vol. 19, no. 12, pp. 4443-4455, 2020.

P. Pavelková, A. Krmela, and V. Schulzová, “Determination of carotenoids in flowers and food supplements by HPLC-DAD,” Acta Chimica Slovaca, vol. 13, pp. 6-12, 2020.

W. Haddar, I. Elksibi, N. Meksi, and M. F. Mhenni, “Valorization of the leaves of fennel (Foeniculum vulgare) as natural dyes fixed on modified cotton: A dyeing process optimization based on a response surface methodology,” Industrial Crops and Products, vol. 52, pp. 588-596, 2014.

I. Puertas Arbizu, and C. J. Luis Pérez, “Surface roughness prediction by factorial design of experiments in turning processes,” Journal of Materials Processing Technology, vol. 143, pp. 390-396, 2003.

P. Pisitsak, N. Tungsombatvisit, and K. Singhanu, “Utilization of waste protein from Antarctic krill oil production and natural dye to impart durable UV-properties to cotton textiles,” Journal of Cleaner Production, vol. 174, pp. 1215-1223, 2018.

T. Inprasit, K. Motina, P. Pisitsak, and P. Chitichotpanya, “Dyeability and antibacterial finishing of hemp fabric using natural bioactive neem extract,” Fibers and Polymers, vol. 19, pp. 2121-2126, 2018.

T. Inprasit, J. Pukkao, N. Lertlaksameephan, A. Chuenchom, K. Motina, and W. Inprasit, “Green dyeing and antibacterial treatment of hemp fabrics using punica granatum peel extracts,” International Journal of Polymer Science, vol. 4, pp. 1-9, 2020.

R. Mongkholrattanasit, M. Nakpathom, and N. Vuthiganond, “Eco-dyeing with biocolorant from spent coffee ground on low molecular weight chitosan crosslinked cotton,” Sustainable Chemistry and Pharmacy, vol. 20, pp. 100389, 2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.