Synthesis of SiC nanowires on biochar surfaces by a simple direct method

DOI:

https://doi.org/10.55713/jmmm.v33i3.1717คำสำคัญ:

SiC synthesis, SiC nanowires, Biochar, PM 2.5 filtrationบทคัดย่อ

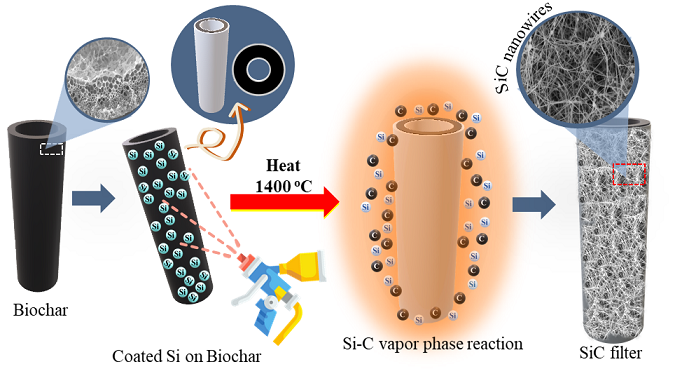

Demand for air filters is crucially required due to PM 2.5. So, SiC nanowire networks are directly grown on biochar surfaces that serve strength and filtering purposes. The nanowires were prepared by spraying silicon powder on Lesser bulrush and Grey sedge biochars which acted as carbon sources and heating up to 1300℃ to 1500℃ for 1 h in Ar atmosphere. As a result, silicon powder evaporated and diffused on biochar surfaces. Meanwhile, CO vapor was generated from biochar reacted with O2 in the chamber. The evaporated silicon reacted with both C(s) and CO(g) to form cubic SiC nanowires. At the early stage of the reaction, large nuclei of SiC nanowires were formed at 1300℃. Those nuclei became smaller to promote nanowires when a higher temperature was applied before being disappeared at 1500℃. At such temperature, the obtained network structure SiC nanowires with 10 nm to 30 nm diameters on the outer and inner surfaces of biochars were completed, facilitating superior strength and filtering purposes. Comparatively, the Lesser bulrush provided higher strength than those of the Grey sedge ones, thus it was selected for the filtering efficiency test. The results showed that particulate filter efficiency was up to 97% but it was still over the range of pressure drop at 30 in H2O.

Downloads

เอกสารอ้างอิง

P. Hu, S. Dong, X. Zhang, K. Gui, G. Chen, and Z. Hu, “Synthesis and characterization of ultralong SiC nanowires with unique optical properties, excellent thermal stability and flexible nanomechanical properties,” Scientific Reports, vol. 7, p. 3011, 2017.

W. Yang, W. Wang, and C. Xie, “Large-scale growth of patterned SiC nanowire arrays and their field emission performance,” Journal of the American Ceramic Society, vol. 102, pp. 3854-3859, 2019.

M. Dragomir, M. Valant, and M. Fanetti, “A facile chemical method for the synthesis of 3C-SiC Nanoflakes,” RSC. Advances, vol. 6, pp. 21795-21801, 2016.

H. Mousa, and K. Teker, “High-transconductance silicon carbide nanowire-based field-effect transistor (SiC-NWFET) for high-temperature applications,” Microelectronics International, vol. 38, no. 2, pp. 78-83, 2021.

X. Chen, Y. Qin, Q. Jia, Q. Zhang, Y. Zhou and X. Liu, "Synthesis of blue-green photoluminescent β-SiC nanowires via a simple catalyst-free CVD technique,” Materials Letters, vol. 234, pp. 187-190, 2019.

G. P. Ojha, G. W. Kang, Y.-S. Kuk, Y. E. Hwang, O. H. Kwon, B. Pant, J. Acharya, Y. W. Park, and M. Park, “Silicon Carbide nanostructures as potential carbide material for electrochemical supercapacitors: A review,” Nanomaterials, vol. 13, Article 150, 2023.

K. Zekentes, J. Choi, V. Stambouli, E. Bano, O. Karker, and

K. Rogdakis, “Progress in SiC nanowire field-effect-transistors for integrated circuits and sensing applications,” Microelectronic Engineering, vol. 255, Article 111704, 2022.

A. Boukezzata, A. Kebaili, A. Bouhamed, S. Bouanik, A. Manseri, H. Cheraga, S. Kaci, L. Guerbous, and H. Menari, “Elaboration and characterization of a-SiC nanowires for CO2 sensor,” Applied Physics A, vol. 127, article 775, 2021.

Z. Shen, J. Chen, B. Li, G. Li, Z. Zhang, and X. Hou, Recent progress in SiC nanowires as electromagnetic microwaves absorbing materials,” Journal of Alloys and Compounds, vol. 815, Article 152388. 2020.

X. Li, Q. Liu, S. Chen, W. Li, Z. Liang, Z. Fang, W. Yang, Y. Tian, and Y. Yang, “Quasi-aligned SiC@C nanowire arrays as free-standing electrodes for high-performance micro-super capacitors,” Energy Storage Materials, vol. 27, pp. 261-269, 2020.

W. F. Li, and H.S. Guo, “A novel and green fabrication of 3C-SiC nanowires from coked rice husk-silicon mixture and their photoluminescence property,” Materials Letter, vol. 215, pp. 75-78, 2018.

S. Liu, and J.G. Wang, “Room-temperature magnetic properties of SiC based nanowires synthesized via microwave heating method,” Physica E, vol. 81, pp. 268-274, 2016.

A. Paka, A. Ivashutenkoa, A. Zakharovab, and Y. Vassilyevaa, “Cubic SiC nanowire synthesis by DC arc discharge under ambient air conditions,” Surface and Coatings Technology, vol. 387, no. 15, p. 125554, 2020.

Xiang-min Xie, Zhe-an Su, Dong Huang, Cheng Yang, Ya-feng Wang, Ding-yu Jiang, and Qi-zhong Huang, “Synthesis and growth mechanism of SiC/SiO2 nanochains by catalyst-free thermal evaporation method in Ar/CO atmosphere,” Transactions of Nonferrous Metals Society of China, vol. 30, pp. 3058-3066, 2020.

J.-M. Qian, J.-P. Wang, G. J. Qiao, and Zh.-H. Jin, “Preparation of porous SiC ceramic with a woodlike microstructure by sol-gel and carbothermal reduction processing,” Journal of the European Ceramic Society, vol. 24, pp. 3251–3259, 2004.

H. Liu, C. Deng, X. Wang, C. Yu, J. Ding, and H. Zhu, “Facile preparation of morph-genetic SiC/C porous ceramic at low temperature by processed bio-template,” Ceramic International, vol. 46, no. 4, pp. 4351-4357, 2019.

W. Khongwong, M. Imai, K. Yoshida, and T. Yano, “Influence of raw powder size, reaction temperature, and soaking time on synthesis of SiC/SiO2 coaxial nanowires via thermal evaporation,” Journal Ceramic Society Japan, vol. 117, no. 4, pp. 439-444, 2009.

W. Khongwong, M. Imai, K. Yoshida, and T. Yano, “Simple approach to fabricate SiC-SiO2 composite nanowires and their oxidation resistance,” Material Science and Engineer B., vol. 173, 117-121, 2010.

A. Gómez-Martín, M. P. Orihuela, J. A. Becerra, J. Martínez-Fernández, and J. Ramírez-Rico, “Permeability and mechanical integrity of porous biomorphic SiC ceramics for application as hot-gas filters, Materials and Design, vol. 107, pp. 450-460, 2016.

E. Eray, V. Boffa, M. K. Jørgensen, G. Magnacca, and V. M. Candelario, “Enhanced fabrication of silicon carbide membranes for wastewater treatment: From laboratory to industrial scale,” Journal of Membrane Science, vol. 606, Article 118080, 2020.

M. Liao, C. Guo, W. Guo, T. Hu, H. Qin, P. Z. Gao, and H. Xiao, “Hydrogen production in microreactor using porous SiC ceramic with a pore-in-pore hierarchical structure as catalyst support,” International Journal of Hydrogen Energy, vol. 45, no. 41, pp. 20922-20932, 2020.

X. Tian, X. Chen, C. Ma, K. Su, Q. Geng, F. Zhao, and X. Liu, “Green synthesis of blue-green photoluminescent β-SiC nano-wires with core-shell structure using coconut shell as carbon source,” Ceramics International, vol. 48, pp. 36273-36278, 2022.

W. Wong-Ng, “Crystallite size,” in Handbook of International Tables for crystallography, vol. H Powder diffraction, ed C. J. Gilmore, J. A. Kaduk and H. Schenk: Wiley Publishing, 2019, pp. 815-816, 2019.

P. Intra, and V. Asanavijit, “Particle filtration efficiency of N95 mask, KN95 mask and surgical mask in the particle size range between 15-700 nm”, The journal of King Mongkut’s University of Technology North Bangkok (KMUTNB), Dec. 2021 (in press).

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.