The changes in microstructural features and physical properties of ceramic matrix composite bonding tools under ultrasonic service

DOI:

https://doi.org/10.55713/jmmm.v33i3.1709Keywords:

Ultrasonic bonding, Bonding tool, Microstructures, CharacterizationAbstract

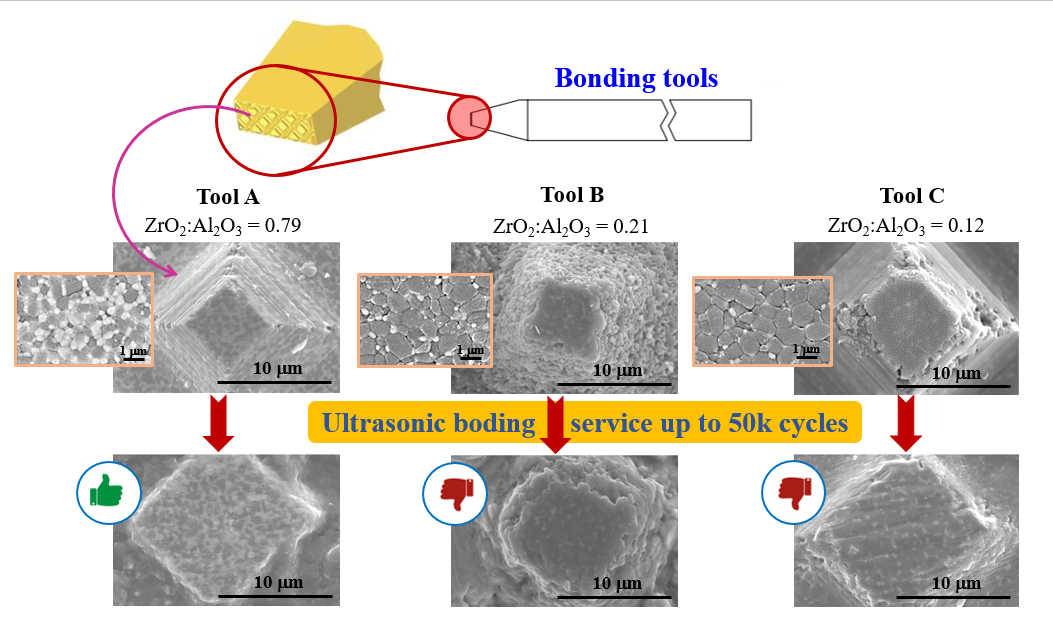

Tape automated bonding (TAB) process plays a key role in the production of disk drives, microchips and other microelectronics components. Such tools should sustain their structures and properties throughout ultrasonic operation and are expected to last until reaching the targeted numbers of TAB cycles. This project aims to evaluate the changes in microstructures and physical properties of the bonding tools under ultrasonic service. Three commercial waffle-type tools from different suppliers were focused, namely Tool A, Tool B and Tool C. They provide different levels of bonding efficiency up to 50k cycles under relatively similar ultrasonic practice. Non-destructive and destructive testing methods were examined by the means of X-Ray and mass spectroscopy techniques, respectively. The waffle-end tips of the selected tool were observed using a confocal microscope. The changes in grain size and grain size distribution before and after ultrasonic service were quantitatively analyzed via electron micrographs. Also, their bulk density, hardness and toughness were determined. The experimental work revealed the variation in microstructural features and properties among the three, leading to the difference in ultrasonic efficiency, even they all contained similar phase composition. The relationship between microstructures, properties and ultrasonic efficiency was also reported and discussed.

Downloads

References

Coorstek Inc., Gaiser® precision bonding tools. Product catalog, 2015.

Small Precision Tools, Bonding capillaries: Bonding evolution. Product Catalog.

Micro Point Pro, TAB and magnetic head bonding tools. Product Catalog.

I. Lum, Effects of ultrasound in microelectronic ultrasonic wire bonding. PhD Thesis, Canada: University of Waterloo, Library and Archive Canada, Published Heritage Branch, 2007.

D. K. Pandey, and S. Pandey, “18 - Ultrasonics: A technique of material characterization,” Acoustic Wave, ed Dissanayake: Intech, 2010, pp. 298-430.

S. F. Reiber, Bonding tool. Patent Application Publication, US2008/0197172A1 August 21, 2008.

T. Nakano, Ultrasonic bonding tool and ultrasonic bonding method. Patent Application Publication, US10625475B2 April 21, 2020.

W. J. Greig, “9 - Tape automated bonding - TAB,” in Integrated circuit packaging, assembly and interconnections, Springer, 2007, pp.129-141.

Small Precision Tools, Gold and aluminum bonding wedge: bonding spectrum. Product Catalog.

H. Ma, and B. Zhao, “Prohibition effects on the crack propagation of Al2O3-ZrO2 nano-composite ceramics under ultrasonic vibration,” Key Engineering Materials, vol. 426-427, pp.147-150, 2010.

M. Boniecki, T. Sadowski, P. Gołębiewski, H. Węglarz, A. Piątkowska, M. Romaniec, K. Krzyżak and K. Łosiewicz, “Mechanical properties of alumina/zirconia composites,” Ceramics International, vol. 46, pp. 1033-1039, 2020.

H. Carreon, A. Ruiz, A. Medina, G. Barrera, and J. Zarate, “Characterization of the alumina zirconia composite system by ultrasonic velocity measurements,” Materials Characterization, vol. 60, no. 8, pp. 875-881, 2009.

K. S. Tan, and P. Hing, “Ultrasonic through-transmission method of evaluating the modulus of elasticity of Al2O3–ZrO2 composite,” Journal of Materials Science, vol. 32, pp. 6633-6638, 1997.

K. Tanaka, “Elastic/plastic indentation hardness and indentation fracture toughness: the inclusion core model,” Journal of Materials Science, vol. 22, pp. 1501-1508, 1987.

D. Ćorić, M. M. Renjo, and L. Ćurković, “Vickers indentation fracture toughness of Y-TZP dental ceramics,” International Journal of Refractory Metals and Hard Materials, vol. 64, pp. 14-19, 2017.

T. Ferreira, and W. Rasband, ImageJ user guide IJ 1.46r. Revised edition, 2004.

Y. Yan, P. L. Xu, and B. Zhao, “Surface phase transformation analysis of nanozirconia toughened alumina ceramics under two-dimensional ultrasonic vibration grinding,” Applied Mechanics and Materials, vol. 42, pp. 259-262, 2010.

F. Sergejev, and M. Antonov, “Comparative study on indentation fracture toughness measurements of the cemented carbides,” Estonian Journal of Engineering, vol. 12, no. 4, pp. 388-398, 2006.

C. F. Luk, Y. C. Chan, and K. C. Hung, “Development of gold to gold interconnection flip chip bonding suspension assemblies,” Microelectron Reliability, vol. 42, p. 3810389.

J. Onpimai, and K. Tangchaichit, “A study on factors affecting the head stack assembly (HSA) in ultrasonic tab bonding process,” Khon Kaen University Research Journal, vol. 16, no. 4, pp. 391-397, 2011.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Journal of Metals, Materials and Minerals

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.