Investigation of oxide scale adhesion on hot-rolled steel using the tensile test and acoustic emission

DOI:

https://doi.org/10.55713/jmmm.v33i2.1579คำสำคัญ:

tensile test, acoustic emission, oxide scale, adhesion, hot-rolled steel coilบทคัดย่อ

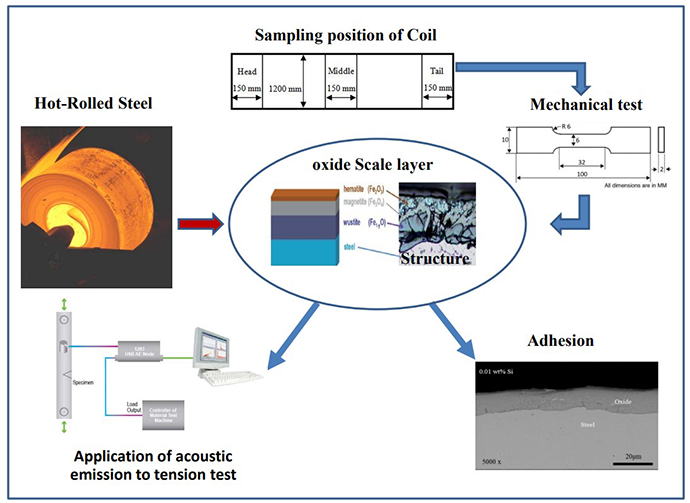

This article addresses applying a tensile test with a CCD camera to assess scale adhesion on hot-rolled steel as a function of hot-rolled coil position. The scale adhesion in this study was shown in the value of the strain initiating the first scale spallation. The result of strain initiating the first scale spallation was confirmed with an acoustic emission (AE) method. The as-received hot-rolled coil was studied at the head, middle, and tail positions. A scanning electron microscope (SEM) and X-ray diffraction (XRD) were used to examine the scale morphology and phase identification respectively. The results show that the oxide scale comprises hematite and magnetite layers. It was found that the higher strain initiating the first scale spallation was revealed on the scale formed on the hot-rolled coil at the head and middle positions. This indicates that the oxide scale was more difficult to remove than at the tail position of the coil. The scale growth and cooling affects the stresses on the oxide layer and the steel substrate. A thin oxide layer on tail position of the hot-rolled coil will easily first crack and then buckle and followed by spallation, while a thick scale on head and middle positions of the hot-rolled coil was harder than that thin scale.

Downloads

เอกสารอ้างอิง

P. Kofstad, High temperature corrosion. Elsevier Applied Science, London, 1988.

R. Y. Chen, and W. Y. D. Yuen, “Oxide-scale structures formed on commercial hot-rolled steel strip and their formation mechanisms,” Oxidation of Metals, vol. 56, no. 1/2, pp. 89-118, 2001.

R. Y. Chen, and W. Y. D. Yuen, “Oxidation of low-carbon, low-silicon mild steel at 450-900°C under conditions relevant to hot-strip processing,” Oxidation of Metals, vol. 57, no. 1/2, pp. 53-79, 2002.

R. Y. Chen, and W. Y. D. Yuen, “Review of the high-temperature oxidation of iron and carbon steels in air or oxygen,” Oxidation of Metals, vol. 59, no. 5/6, pp. 433-468, 2003.

R. Y. Chen, and W. Y. D. Yuen, “Examination of oxide scales of hot rolled steel products,” Iron and Steel Institute of Japan International, vol. 45, no. 1, pp. 52-59, 2005.

P. Sarrazin, A. Galerie, and J. Fouletier, Les mécanismes de la corrosion sèche: uneapprochecinétique. France: EDP Science, 2000.

P. Sarrazin, A. Galerie, and J. Fouletier, Mechanisms of high temperature corrosion: a kinetic approach. Zürich: Materials Science Foundations, Trans Tech Publications, 2008.

M. J. L. Gines, G. J. Benitez, T. Perez, E. Merli, M. A. Firpo, and W. Egli, “Study of the picklability of 1.8 mm hot-rolled steel strip in hydrochloric acid,” Latin American Applied Research, pp. 281-288, 2002.

Z. Y. Jiang, A. K. Tieu, W. H. Sun, J. N. Tang, and D. B. Wei, “Characterisation of thin oxide scale and its surface roughness in hot metal rolling,” Materials Science and Engineering A, vol. 435-436, pp. 434-438, 2006.

L. Suárez, R. Petrov, L. Kestens, M. Lamberigts, and Y. Houbaert, “Texture evolution of tertiary oxide scale during steel plate finishing hot rolling simulation tests,” Materials Science Forum, vol. 550, pp. 557-562, 2007.

M. Zhang, and G. Shao, “Characterization and properties of oxide scales on hot-rolled strips,” Materials Science and Engineering A, vol. 452-453, pp. 189-193, 2007.

Y. -L. Yang, C. -H. Yang, S. -N. Lin, C. -H. Chen, and W. -T. Tsai, “Effects of Si and its content on the scale formation on hot-rolled steel strips,” Materials Chemistry and Physics, vol. 112, pp. 566-571, 2008.

A. Segawa, “Reproduction and deformation characteristics of oxide scale in hot rolling using vacuum rolling mill,” Materials Science Forum, vol. 96, pp. 150-155, 2011.

S. Chandra-ambhorn, T. Phadungwong, and K. Sirivedin, “Effects of carbon and coiling temperature on the adhesion of thermal oxide scales to hot-rolled carbon steels,” Corrosion Science, vol. 115, pp. 30-40, 2017.

S. Chandra-ambhorn, T. Nilsonthi, Y. Wouters, and A. Galerie, “Oxidation of simulated recycled steels with 0.23 and 1.03 wt.% Si in Ar–20% H2O at 900°C,” Corrosion Science, vol. 87, pp. 101-110, 2014.

R. Y. Chen, and W. Y. D. Yuen, “Isothermal and step isothermal oxidation of copper-containing steels in air at 980-1220°C,” Oxidation of Metals, vol. 63, no. 3/4, pp. 145-168, 2005.

S. Chandra-ambhorn, A. Jutilarptavorn, and T. Rojhirunsakool, “High temperature oxidation of irons without and with 0.06 wt% Sn in dry and humidified oxygen,” Corrosion Science, vol. 148, pp. 355-365, 2019.

S. Chandra-ambhorn, and K. Ngamkham, “High temperature oxidation of micro-alloyed steel and its scale adhesion,” Oxidation of Metals, vol. 88, pp. 291-300, 2017.

R. Y. Chen, and W. Y. D. Yuen, “A study of the scale structure of hot-rolled steel strip by simulated coiling and cooling,” Oxidation of Metals, vol. 53, no. 5/6, pp. 539-560, 2000.

R. Y. Chen, and W. Y. D. Yuen, “Copper enrichment behaviours of copper-containing steels in simulated thin-slab casting processes,” Iron and Steel Institute of Japan International, vol. 45, no. 6, pp. 807-816, 2005.

S. Chandra-ambhorn, K. Ngamkham, and N. Jiratthanakul, “Effects of process parameters on mechanical adhesion of thermal oxide scales on hot-rolled low carbon steels,” Oxidation of metals, vol. 80, no. 1, pp. 61-72, 2013.

H. E. Evans, “Stress effects in high temperature oxidation of metals,” International Materials Reviews, vol. 40, no. 1, pp. 1-40, 1995.

H. E. Evans, “Spallation of oxide from stainless steel AGR nuclear fuel cladding: mechanisms and consequences,” Materials Science and Technology, vol. 4, pp. 415-420, 1988.

B. A. Kschinka, and J. F. Stubbins, “Creep-fatigue-environment interaction in a bainitic 2.25wt.%Cr-1wt.%Mo steel forging,” Materials Science & Engineering A, vol. 110, pp. 89-102, 1989.

J. K. Tien, and J. M. Davidson, Stress effects and the oxidation of metals. ed J. V. Cathcart, New York, AIME, 1975.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2023 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.