Preparation of feedstock containing water-soluble binder for powder injection moulding of silver

DOI:

https://doi.org/10.55713/jmmm.v32i3.1271คำสำคัญ:

Powder injection moulding, Silver, Polyethylene glycol, Feedstockบทคัดย่อ

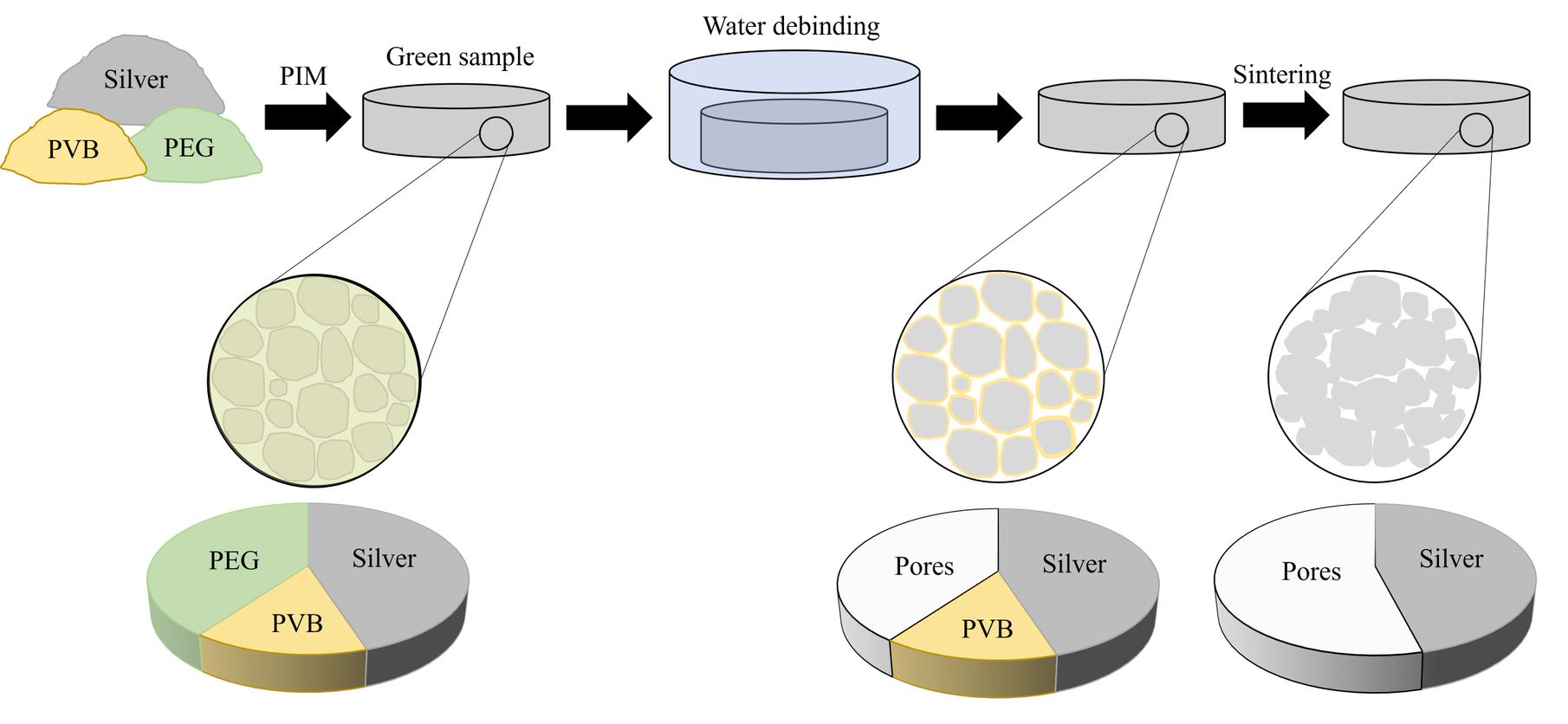

Feedstock for powder injection moulding of silver was prepared using water-soluble binder composed of polyethylene glycol (PEG) and polyvinyl butyrol (PVB). Silver powders with particle size in range of 1 μm to 20 μm can be mixed with PEG/PVB binder system to form feedstocks having powder loadings of 42 vol% and 45 vol%. PEG can be removed using water leaching method while PVB can be removed by thermal debinding. Specimens retained their shapes during debinding and after debinding. Components fabricated with relatively higher powder loading resulted in higher density with lower porosity. Density of specimens containing powder loading of 42 vol% and 45 vol% and heated at 700℃ is about 43% and 46% of the theoretical value, respectively. Therefore, it can be further developed for porous materials applications.

Downloads

เอกสารอ้างอิง

S. Amaranan, and A. Manonukul, “Study of process parameters in conventional powder metallurgy of silver,” Journal of Metals, Materials, and Minerals, vol. 20, no. 1, pp.51-55, 2010.

E. Biguereau, D. Bouvard, J. M. Chaix, and S. Roure, “On the swelling of silver powder during sintering,” Powder Metallurgy, vol. 59, no. 5, pp. 394-400, 2016. DOI: https://doi.org/10.1080/00325899.2016.1250037

N. Chuankrerkkul, K. Somton, T. Wonglom, K. Dateraksa, and P. Laoratanakul, “Physical and mechanical properties of zirconia toughened alumina (ZTA) composites fabricated by powder injection moulding,” Chiang Mai Journal of Science, vol. 43, no. 2, pp. 375-380, 2016.

A. J. Medesi, D. Nötzel, and T. Hanemann, “PVB/PEG-based feedstocks for injection molding of alumina microreactor components,” Materials, vol. 12, no. 8, p. 1219, 2019. DOI: https://doi.org/10.3390/ma12081219

J. Strauss, “The potential of PIM for the manufacture of precious metal jewellery,” Powder Injection Moulding International, vol. 2, no. 2, pp. 50-54, 2008.

B. Williams, “Watch cases and bracelet parts: PIM moves upmarket,” Powder Injection Moulding International, vol. 2, no. 2, pp. 31-32, 2008.

A. Basir, A. B. Sulong, N. H. Jamadon, N. Muhamad, and U. B. Emeka, “Process parameters used in macro/micro powder injection molding: an overview,” Metals and Materials International, vol. 27, no. 7, pp. 2023-2045, 2021. DOI: https://doi.org/10.1007/s12540-020-00767-w

M. R. Raza, A. B. Sulong, N. Muhamad, M. N. Akhtar, and J. Rajabi, “Effects of binder system and processing parameters on formability of porous Ti/HA composite through powder injection molding,” Materials & Design, vol. 87, pp. 386-392, 2015. DOI: https://doi.org/10.1016/j.matdes.2015.08.031

S. Rolere, U. Soupremanien, M. Bohnke, M. Dalmasso, C. Delafosse, and R Laucournet, “New insights on the porous network created during solvent debinding of powder injection-molded (PIM) parts, and its influence on the thermal debinding efficiency,” Journal of Materials Processing Technology, vol. 295, p. 117163, 2021. DOI: https://doi.org/10.1016/j.jmatprotec.2021.117163

S. Md Ani, A. Muchtar, N. Muhamad, and J. A. Ghani, “Binder removal via a two-stage debinding process for ceramic injection molding parts,” Ceramics International, vol. 40, no. 2, pp. 2819-2824, 2014. DOI: https://doi.org/10.1016/j.ceramint.2013.10.032

M. Song, M. S. Park, J. K. Kim, I.B. Cho, K. H. Kim, H. J. Sung, and S. Ahn, “Water-soluble binder with high flexural modulus for powder injection molding,” Journal of Materials Science, vol. 40, no. 5, pp. 1105-1109, 2005. DOI: https://doi.org/10.1007/s10853-005-6924-2

N. Chuankrerkkul, P. Sooksaen, P. Pakunthod, T. Kosalwit, and W. Pinthong, “Powder injection moulding of alumina using PEG/PVB binder systems,” Key Engineering Materials, vol. 545, pp. 173-176, 2013. DOI: https://doi.org/10.4028/www.scientific.net/KEM.545.173

G.Thavanayagam, and J. E. Swan, “Aqueous debinding of polyvinyl butyral based binder system for titanium metal injection moulding,” Powder Technology, vol. 326, pp. 402-410, 2018. DOI: https://doi.org/10.1016/j.powtec.2017.11.069

W. Buggakupta, T. Wasanapiarnpong, and N. Chuankrerkkul, “Debinding behaviour and sintering temperature-dependent features of coloured zirconia fabricated by ceramic injection moulding,” Journal of Metals, Materials, and Minerals, vol. 31, no. 2, pp. 84–88, 2021. DOI: https://doi.org/10.55713/jmmm.v31i2.1056

N. Saelee, N. Chuankrerkkul, and P. Wanakamol, “Microstructure and properties of zirconia-alumina composites fabricated via powder injection molding,” Journal of Metals, Materials, and Minerals, vol. 31, no. 1, pp. 73-80, 2021. DOI: https://doi.org/10.55713/jmmm.v31i1.1019

N. Chuankrerkkul, and P. Chakartnarodom, “Fabrication of injection moulded 304L stainless steels reinforced with tungsten carbide particles,” Materials Science Forum, vol. 706-709, pp. 638-642, 2012. DOI: https://doi.org/10.4028/www.scientific.net/MSF.706-709.638

W. Buggakupta, R. Uehara, and N. Chuankrerkkul, “Study on binder removal and green properties of tungsten carbide-nickel hardmetals fabricated by powder injection moulding,” Chiang Mai Journal of Science, vol. 47, no. 2, pp. 343-348, 2020.

N. Chuankrerkkul, P. F. Messer, and H.A. Davies, “Flow and void formation in powder injection moulding feedstocks made with PEG/PMMA binders Part 2 – Slip band model,” Powder Metallurgy, vol. 51, no. 1, pp. 72-77, 2008. DOI: https://doi.org/10.1179/174329008X271628

R. M. German, and A. Bose, Injection Molding of Metals and Ceramics. New Jersey: Metal Powder Industries Federation, 1997.

G. Thavanayagam, K. L. Pickering, J. E. Swan, and P. Cao, “Analysis of rheological behaviour of titanium feedstocks formulated with a water-soluble binder system for powder injection moulding,” Powder Technology, vol. 269, pp. 227-232, 2015. DOI: https://doi.org/10.1016/j.powtec.2014.09.020

B. Loebbecke, R. Knitter, and J. Haußelt, “Rheological properties of alumina feedstocks for the low-pressure injection moulding process,” Journal of the European Ceramic Society, vol. 29, no. 9, pp. 1595-1602, 2009. DOI: https://doi.org/10.1016/j.jeurceramsoc.2008.11.001

G. Alva, Y. Lin, and G. Fang, “Thermal and electrical characterization of polymer/ceramic composites with polyvinyl butyral matrix,” Materials Chemistry and Physics, vol. 205, pp. 401-415, 2018. DOI: https://doi.org/10.1016/j.matchemphys.2017.11.046

E. A. Oliber, C. Cugno, M. Moreno, M. Esquivel, N. Haberkorn, J. E. Fiscina, and C J. R. Gonzalez Oliver, “Sintering of porous silver compacts at controlled heating rates in oxygen and argon,” Materia Revista, vol. 8, no. 4, pp. 350-357, 2003.

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

ฉบับ

บท

การอนุญาต

ลิขสิทธิ์ (c) 2022 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.