Use of commercial synthetic filament waste to reinforce biobased poly(butylene succinate) with the aid of compatibilizers

DOI:

https://doi.org/10.55713/jmmm.v34i3.1947คำสำคัญ:

Poly(butylene succinate), synthetic filament, Composite, HMDI, HMDAบทคัดย่อ

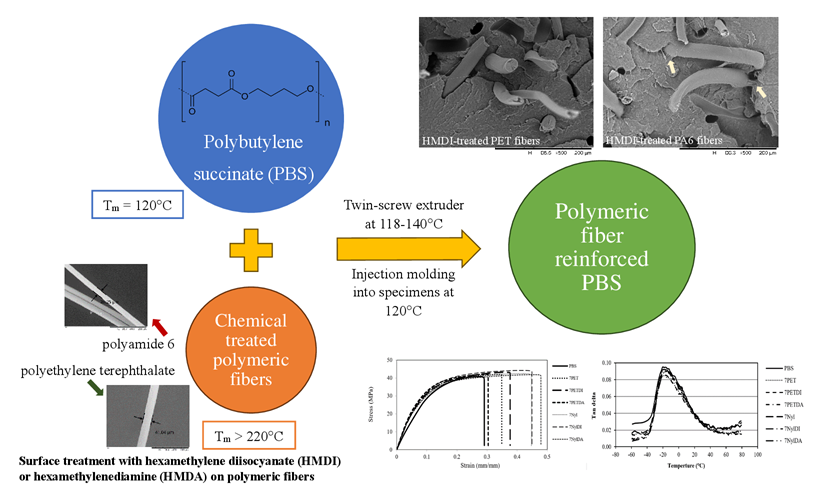

Since poly(butylene succinate) (PBS) has low rigidity for engineering application, this research attempted to reinforce PBS with poly(ethylene terephthalate) (PET) and polyamide-6 (nylon6) filaments with the reservation of polymer toughness. Filaments were chopped to be short fibers (length of 2 mm to 4 mm) and melt compounded with PBS pellets in the weight ratio of 1 wt%, 5 wt%, and 7 wt% using a twin-screw extruder that the temperature profile was set high enough for melting only PBS matrix. Two types of compatibilizers; hexamethylene diisocyanate (HMDI) or hexamethylene diamine (HMDA) of 0.05 wt% were used to treat fiber surface. It was found that tensile modulus of PBS increased with respect to fiber concentration, which untreated PET fibers provided higher tensile modulus about 2% to 7%. Surface treatment of fibers with either HMDI or HMDA increased rigidity of the composites, while elongation at break and impact strength were also improved with respect to fiber concentration. Also, shifting in glass transition temperature of PBS by DMA indicated improved interfacial interaction, which HMDA treatment gave the best benefit for mechanical properties. Number-average molecular weight of HMDI-treated composites was closed to extruded PBS, however, those of HMDA-treated composites were reduced dramatically implying chain scission highly occurred. SEM micrographs revealed good interfacial adhesion obtained after fiber treatment. Crystallization of PBS studied by XRD showed that the crystal form was not affected by the compatibilizer.

Downloads

เอกสารอ้างอิง

J. H. Schut, "Waiting for Bio PBS," in Plastics Engineering Blog vol. 2016, ed. Worldpress.com: Society of Plastics Engineers, 2014.

C. P. Hebdo, "Succinic acid: More projects for biosourced production," Focus on Catalysts, vol. 2009, no. 12, pp. 5-6 DOI: https://doi.org/10.1016/S1351-4180(09)70518-5

A. A. A. Alim, A. Baharum, S. S. M. Shirajuddin, and F. H. Anuar, "Blending of low-density polyethylene and poly(butylene succinate) (LDPE/PBS) with polyethylene–graft–maleic anhydride (PE–g–MA) as a compatibilizer on the phase morphology, mechanical and thermal properties," Polymers, vol. 15, no. 2, pp. 261, 2023. DOI: https://doi.org/10.3390/polym15020261

O. Akampumuza, P. M. Wambua, A. Ahmed, W. Li, and X. Qin, "Review of the applications of biocomposites in the automotive industry," Polymer Composites, pp. 1-17, 2016. DOI: https://doi.org/10.1002/pc.23847

F. Yan-Hong, L. Yi-Jie, X. Bai-Ping, Z. Da-Wei, Q. Jin-Ping, and H. He-Zhi, "Effect of fiber morphology on rheological properties of plant fiber reinforced poly(butylene succinate) composites," Composites Part B: Engineering, vol. 44, no. 1, pp. 193-199, 2013. DOI: https://doi.org/10.1016/j.compositesb.2012.05.051

Y. Feng, H. Shen, J. Qu, B. Liu, H. He, and L. Han, "Preparation and properties of PBS/sisal-fiber composites," Polymer Engineering & Science, vol. 51, no. 3, pp. 474-481, 2011. DOI: https://doi.org/10.1002/pen.21852

L. S. Yi Li, Z. Wei, C. Ding, Y. Chang, G. Chen, W. Zhang, and J. Liang, "Mechanical properties and crystallization behavior of poly(butylene succinate) composites reinforced with basalt fiber," Journal of Thermal Analysis and Calorimetry, vol. 122, pp. 261-270, 2015. DOI: https://doi.org/10.1007/s10973-015-4732-8

E. Frollini, N. Bartolucci, L. Sisti, and A. Celli, "Poly(butylene succinate) reinforced with different lignocellulosic fibers," Industrial Crops and Products, vol. 45, pp. 160-169, 2013. DOI: https://doi.org/10.1016/j.indcrop.2012.12.013

M. Zhou, Y. Li, C. He, T. Jin, K. Wang, and Q. Fu, "Interfacial crystallization enhanced interfacial interaction of poly(butylene succinate)/ramie fiber biocomposites using dopamine as a modifier," Composites Science and Technology, vol. 91, pp. 22-29, 2014. DOI: https://doi.org/10.1016/j.compscitech.2013.11.019

S. Y. Cho, M. E. Lee, H. W. Kwak, and H.-J. Jin, "Surface-modified cellulose nanocrystal-incorporated poly(butylene succinate) nanocomposites," Fibers and Polymers, vol. 19, pp. 1395-1402, 2018. DOI: https://doi.org/10.1007/s12221-018-8138-7

R.-y. Chen, W. Zou, H.-c. Zhang, G.-z. Zhang, Z.-t. Yang, G. Jin, and J.-p. Qu, "Thermal behavior, dynamic mechanical properties and rheological properties of poly(butylene succinate) composites filled with nanometer calcium carbonate," Polymer Testing, vol. 42, pp. 160-167, 2015. DOI: https://doi.org/10.1016/j.polymertesting.2015.01.015

J. Huang, X. Lu, N. Zhang, L. Yang, M. Yan, H. Liu, G. Zhang, and J. Qu, "Study on the properties of nano-TiO2/ polybutylene succinate composites prepared by vane extruder," Polymer Composites, vol. 35, no. 1, pp. 53-59, 2014. DOI: https://doi.org/10.1002/pc.22633

F. B. Ali, and R. Mohan, "Thermal, mechanical, and rheological properties of biodegradable polybutylene succinate/carbon nanotubes nanocomposites," Polymer Composites, vol. 31, no. 8, pp. 1309-1314, 2010. DOI: https://doi.org/10.1002/pc.20913

A. K. Maurya, S. Kumar, M. Singh, and G. Manik, "Polyamide fiber reinforced polymeric composites: A short review," Volume 80, Part 1, vol. 80, no. 1, pp. 98-103, 2023. DOI: https://doi.org/10.1016/j.matpr.2022.10.171

T. N. Abraham, and K. E. George, "Studies on recyclable nylon-reinforced PP composites: Effect of fiber diameter," Journal of Thermoplastic Composite Materials, vol. 22, no. 1, pp. 5-20, 2009. DOI: https://doi.org/10.1177/0892705708091603

F. Ke, X. Jiang, H. Xu, J. Ji, and Y. Su, "Ternary nano-CaCO3/ poly(ethylene terephthalate) fiber/polypropylene composites: Increased impact strength and reinforcing mechanism," Composites Science and Technology, vol. 72, no. 5, pp. 574-579, 2012. DOI: https://doi.org/10.1016/j.compscitech.2012.01.001

S.-H. Lee and S. Wang, "Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent," Composites: Part A, vol. 37, pp. 80-91, 2006. DOI: https://doi.org/10.1016/j.compositesa.2005.04.015

G. N. Onyeagoro, E. G. Ohaeri, I. O. Arukalam, M. J. Uko, U. O. Enwereuzoh, and C. O. Uzoig, "Effects of MAPI/HMDA dual compatibilizer and filler loading on physico-mechanical and water sorption properties of natural rubber/poly (ethylene terephthalate) (PET)/dikanut shell powder bio-composites," British Journal of Applied Science & Technology, vol. 4, no. 23, pp. 3383-3401, 2014. DOI: https://doi.org/10.9734/BJAST/2014/10383

N. Hongsriphan, W. Muangrak, K. Soonthornvacharin, and T. Tulaphol, "Mechanical improvement of poly(butylene succinate) with polyamide short fibers," Macromolecular Symposia, vol. 354, pp. 28-34, 2015. DOI: https://doi.org/10.1002/masy.201400114

Y. J. Phua, N. S. Lau, K. Sudesh, W. S. Chow, and Z. A. M. Ishak, "Biodegradability studies of poly(butylene succinate)/ organo-montmorillonite nanocomposites under controlled compost soil conditions: Effects of clay loading and compatibiliser," Polymer Degradation and Stability, vol. 97, pp. 1345–1354, 2012. DOI: https://doi.org/10.1016/j.polymdegradstab.2012.05.024

T.-x. Jin, M. Zhou, S.-d. Hu, F. Chen, and Q. Fu, "Effect of molecular weight on the properties of poly(butylene succinate)," Chinese Journal of Polymer Science, vol. 32, no. 7, pp. 953-960, 2014. DOI: https://doi.org/10.1007/s10118-014-1463-4

M. Asgari and M. Masoomi, "Tensile and flexural properties of polypropylene/short poly(ethylene terephthalate) fibre composites compatibilized with glycidyl methacrylate and maleic anhydride," Journal of Thermoplastic Composite Materials vol. 28, no. 3, pp. 357-371, 2015. DOI: https://doi.org/10.1177/0892705713484748

B. Tan, J.-p. Qu, L.-m. Liu, Y.-h. Feng, S.-x. Hu, and X.-c. Yin, "Non-isothermal crystallization kinetics and dynamic mechanical thermal properties of poly(butylene succinate) composites reinforced with cotton stalk bast fibers," Thermochimica Acta, vol. 525, pp. 141-149, 2011. DOI: https://doi.org/10.1016/j.tca.2011.08.003

P. Liminana, D. Garcia-Sanoguera, L. Quiles-Carrillo, R. Balart, and N. Montanes, "Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers," Composites Part B: Engineering, vol. 144, pp. 153-162, 2018. DOI: https://doi.org/10.1016/j.compositesb.2018.02.031

P. Rizzarelli and S. Carroccio, "Thermo-oxidative processes in biodegradable poly(butylene succinate)," Polymer Degradation and Stability, vol. 94, pp. 1825-1838, 2009. DOI: https://doi.org/10.1016/j.polymdegradstab.2009.06.007

P. Raffa, M.-B. Coltelli, S. Savi, S. Bianchi, and V. Castelvetro, "Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: An experimental and modelling study," Reactive & Functional Polymers, vol. 72, pp. 50-60, 2012. DOI: https://doi.org/10.1016/j.reactfunctpolym.2011.10.007

H. Zahn and H. Pfeifer, "Aminolysis of polyethylene terephthalate," Polymer, vol. 4, pp. 429-432, 1963. DOI: https://doi.org/10.1016/0032-3861(63)90055-7

A. M. Al-Sabagh, F. Z. Yehia, G. Eshaq, A. M. Rabie, and A. E. ElMetwally, "Greener routes for recycling of polyethylene terephthalate," Egyptian Journal of Petroleum, vol. 25, no. 1, pp. 53-64, 2016. DOI: https://doi.org/10.1016/j.ejpe.2015.03.001

R. M. Musale and S. R. Shukla, "Deep eutectic solvent as effective catalyst for aminolysis of polyethylene terephthalate (PET) waste," International Journal of plastic technology, vol. 20, no. 1, pp. 106-120, 2016. DOI: https://doi.org/10.1007/s12588-016-9134-7

Z. Qiu and W. Yang, "Crystallization kinetics and morphology of poly(butylene succinate)/poly(vinyl phenol) blend," Polymer, vol. 47, pp. 6429-6437, 2006. DOI: https://doi.org/10.1016/j.polymer.2006.07.001

ดาวน์โหลด

เผยแพร่แล้ว

วิธีการอ้างอิง

การอนุญาต

ลิขสิทธิ์ (c) 2024 วารสารโลหะ, วัสดุ และแร่

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors who publish in this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.